Featured Case Studies

Case Studies

.png?width=120&height=80&name=download%20(6).png)

-1.webp?width=80&height=80&name=Retail_0001_walmart%20(1)-1.webp)

Geekplus

Recent Posts

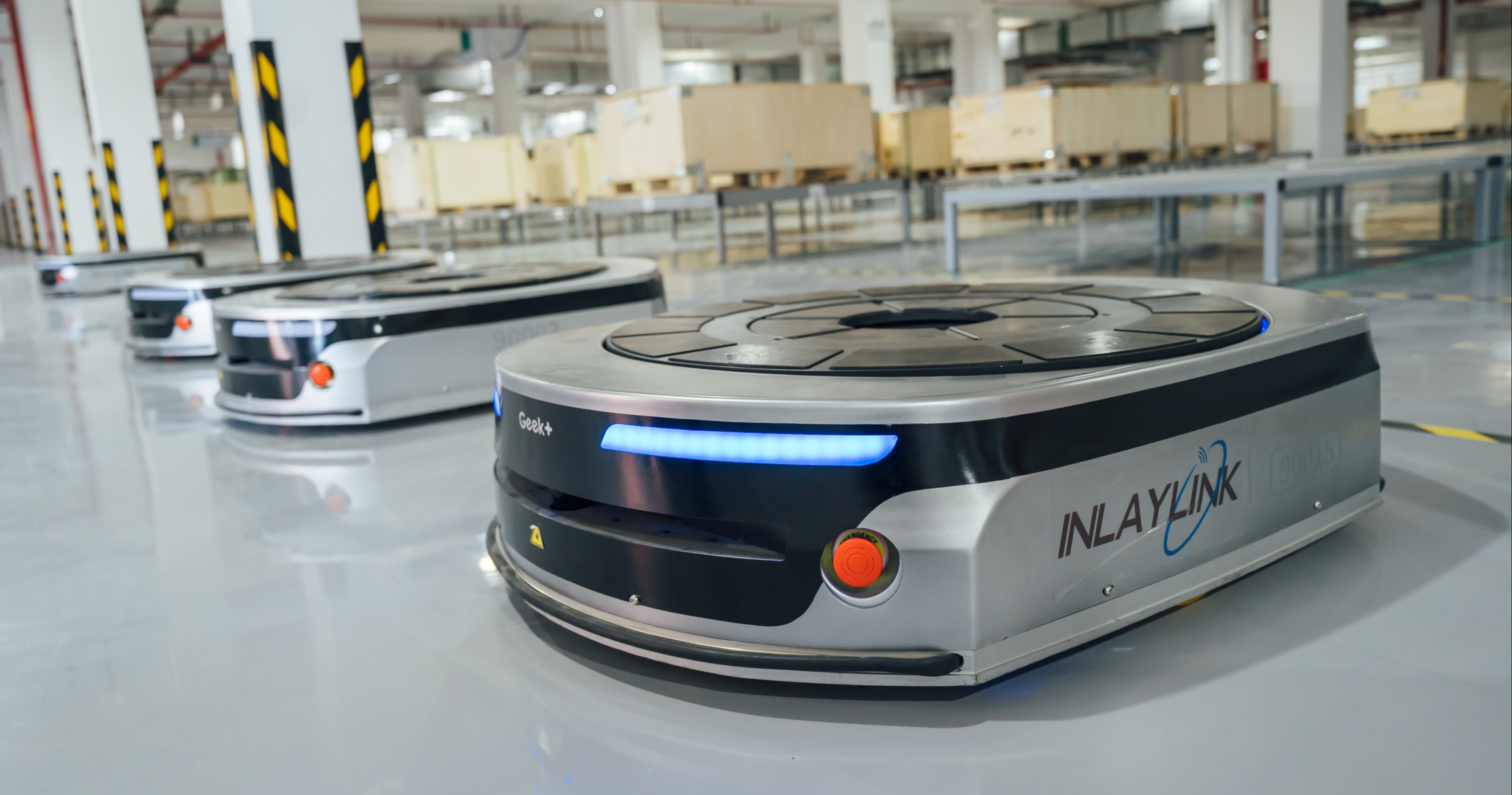

INLAYLINK factory realizes a smart upgrade with moving robots

The Customer

INLAYLINK is one of the world-renowned manufacturers of RFID tag antennas, specializing in the design, research and development, production, and sales of RFID tag antennas. It is also one of the few high-tech companies that can provide RFID data collection solutions and has won many world-known rewards.

The Challenge

- On-site materials are moved across floors and multiple areas frequently, and manual handling cannot guarantee the timeliness

- Manual handling is labor-intensive

- The value of a single material on-site is high. Checking, verification, signing, and handover are required for the delivery, online, offline, and warehousing links.

- The efficiency is low and the management cost is high.

- An information system is required to connect the warehouse and the production line to achieve physical and automatic docking of accounts.

Our Solution

- The site is equipped with 12 M1000 robots that transfers the materials out of the warehouse and sends them to the production lines.

- The robots are connected with vertical warehouse stackers, elevators, access control, and other systems to realize automatic, accurate, and timely distribution of materials across floors and sectors.

- The Geek+ Moving System (GMS) is connected to WMS and MES, enabling real-time visibility of the manufacturing process.

The Geek+ impact

- The integration information allowed a reduction in material management costs by 60%

- Material handling efficiency increased by 30%

- Reduced labor-insensitive operations

Video

Geek+ implements first large-scale AMR sorting system for Banggood’s e-commerce business

The customer

Banggood is a global e-commerce player focused on B2C cross-border export. With 37 international warehouses and deliveries bound for over 200 countries, Banggood is committed to bringing high-quality goods, efficient supply chain and top-class customer service to the world.

The challenge

Due to the accelerated shift towards e-commerce, Banggood faced challenges of rapid growth in online sales, unpredictable demand, labor shortages, and higher requirements for safer operations. With labor-intense processes often subject to inaccurate sorting, the company turned to Geek+ to automate its warehouse and realize and upgrade in its sorting operations.

Our solution

- To meet customer demand, Banggood turned to Geek+ Fleetsort solution, using a combination of S20T and P500 robots and realize more efficient and accurate operations through automated parcel sorting.

The Geek+ impact

- Reduced labor costs

- Reduced investment in fixed facilities

- Significant improvements in sorting efficiency

- 99% sorting accuracy

Geek+ & eStore Logistics partner to implement the largest rollout of AMRs in Australian e-commerce

The customer

eStore Logistics is Australia’s largest 3PL e-commerce fulfillment business. With a network of warehouses in Melbourne and Sydney, eStore strives to enable retailers across Australia to meet higher customer expectations by providing them with accurate, fast, and cost-efficient deliveries.

The challenge

Serving over 50 of Australia’s leading online retailers, eStore Logistics has a very wide SKU range. In turn, eStore Logistics was looking for a technology partner that could support its multi-customer business, flexibly meet rapidly changing SKUs and enable retailers to improve fulfillment performance while remaining profitable.

Our solution

-

On the company’s 26,000 sqm warehouse Geek+ deployed 200 picking robots.

The Geek+ impact

- 30% reduction in logistics costs for eStore’s customers

- Improved same-day delivery service

- Productivity increased by 300%

- 99 % Picking Accuracy

DSV doubled its productivity by deploying Geek+ picking system

The customer

DSV is a global supplier of transport and logistics solutions. With offices and facilities in more than 90 countries on six continents, DSV provides and runs supply chain solutions for thousands of companies on a daily basis.

The challenge

In its Hong Kong warehouse, they have more than 6,000 SKUs of tiny cosmetic items in a 45,000 sq.ft area. Workers take time to walk through the warehouse and spot the right item to fulfill each order. This lowers the picking productivity & accuracy.

Our solution

- Geek+ deployed 42 picking robots, 739 racks & 9 workstations in DSV warehouse. Once DSV received clients' order, Geek+ RMS would control the picking robots to bring the right rack with the right amount of items for workers to fulfill multi-order picking. Workers no longer need to walk through the warehouse.

The Geek+ impact

- Productivity has been doubled

- Improved picking accuracy

- Reduce in labor cost

- Overall 200% increase in bin location and thus increasing storage capacity

- Innovative product application, assist brand marketing effectively

Decathlon Triples Efficiency with Logistics Robots

About Customer

Founded in France in 1976, Decathlon is a professional sports goods retailer specializing in the mass sports market, integrating the entire production chain of sports product design, R&D, production, branding, logistics, and retail. With over 1500 stores in 49 countries, it is the largest sporting goods retailer in the world.

The challenge

The rapid growth of Decathlon's e-commerce business highlighted the limited performance of manual processes. Additionally, as a pioneer of the RFID technology, Decathlon required higher picking efficiency and accuracy to meet its business goals.

Our Solution

- Geek+ provides innovative warehousing solutions for Decathlon’s massive Kunshan warehouse: an RFID technology-based goods-to-person picking and inventory program

- The project area is about 2,000 square meters, with 46 P800 robots, 7 picking stations, and 7 single-point stations. The total inventory of the warehouse is nearly 300,000, involving more than 20,000 SKUs

The Geek+ impact

- Shipment capacity increased to 40,000 pieces/day

- Picking efficiency has reached 300 pieces/hour, 300% increased from manual picking

- Picking system integrated with RFID technology improve inventory management and increase accuracy

- The single-point station adopted to save space and make the operation more flexible

How does retail giant Walmart successfully reduce cost and increase efficiency?

Geek+ robots help Walmart easily handle their massive quantity of SKUs, improving their picking efficiency by about 3.5 times

The customer

Walmart is a multinational retail corporation and the number 1 Fortune 500 company. It operates 8,500 stores worldwide, more than 400 stores in China, 18 logistics distribution centers, and has dozens of new stores opening each year.

The challenge

As the world largest retail chain operating different hypermarket chains and discount stores Walmart faces a variety of challenges with its warehouses including:

- Large volumes in and out of the warehouse; Massive SKUs; Different depth of storage; High volatility;

- Daily orders must be shipped the on same day, and delivery accuracy requirements of 99.99%;

- High error rate and high labor costs of manual picking

Our solution

This is the first time Walmart has used robotic solutions in its warehouses. Geek+ implemented a pilot project in Walmart’s Shenzhen Distribution Center to test the efficiency and adaptability of the Geek+ Picking System with Wal-Mart’s existing operations.

Geek+ deployed 6 picking robots in a 200 square meter pilot area, used for loading and unloading shelves, replenishing shelves, inventory, and performing outbound operations according to order instructions.

The Geek+ impact

- Highly successful pilot project for Walmart’s first robotic solution experience

- Reduced labor intensity

- Improved picking accuracy

- Productivity increased from 149 pieces/person/hour to 533 pieces per person/hour

- Picking efficiency improved by 3.5 times

- Following the successful test, Walmart and Geek+ are expanding its partnership, with 18 more new robots and introducing the robotic solution to Walmart Chile.

Yanfeng swiftly and efficiently completed the behind-the-scenes assistance of its smart factory transformation

Geek+ empowered Yanfeng to achieve faster production pace and better efficiency and stability of its automotive manufacturing solutions.

The customer

Yanfeng focuses on automotive interior and exterior, car seats, cockpit electronics and safety. Since 2010, Yanfeng has actively expanded its presence globally market and has become the world’s largest automotive interior company. It currently has more than 230 factories worldwide and employs more than 65,000 people (including more than 6,700 engineering and design staff).

The challenge

- Cost: Labor costs are rising year by year

- Efficiency: It is increasingly difficult for logistics to meet high-frequency production needs

- Safety: High risk for manual handling

- Management: Unable to conduct WIP inventory management and data traceability

Our solution

- Geek+ provides Yanfeng with 18 P800 for picking and handling and introduces a self-developed inventory process management system

- Geek+ solutions take care of the handling and buffering of finished products after injection molding; before and after secondary processing, and picking and handling before delivery, effectively achieving unmanned and intelligent automation

The Geek+ impact

- 4 production areas are linked with robots for better efficiency, increasing average production tempo to 60s

- Average production tempo increased to 60S

- Feeding flow rate up to 60 cars / hour, twice the efficiency of traditional AGV

- Efficient and timely management of production flow, achieving a neat and organized site layout and scoring a system management accuracy rate of 100%

- Return on investment achieved in less than 2 years

ACCA is the first to introduce Chinese logistics ‘goods to person’ robotic warehouse, fulfilling increasing orders

Geek+ first execution of overseas project marks its official entry into the Japanese market.

The Customer

ACCA is the logistics arm of Daiwa House Group, a leading provider of construction and real estate services in Japan. ACCA is an advanced 3PL in Japan, using robotic automation to improve its operational efficiency.

The Challenge

With a fast increasing sales of shoes and clothes in Japan, more and more warehouse operators have to walk long distances back and forth between the storage area and delivering area. Aging population has increased scarcity and cost of labor. Geek+ solutions help decrease labor costs and make warehouse operations smooth and efficient.

Our Solution

- In 2017, ACCA first introduced 30 P500 P series robots and 800 Sets rack in a 2600㎡ area.

- In 2018, ACCA expanded the operations with 90 additional robots and 2400 Sets rack, with the warehouse expanding to 8000㎡.

The Geek+ impact

- Warehouse area: 8000㎡

- AGV: P500 120 Pcs

- Rack: 3200 Sets

- Working station: 12 Sets

- In the past two years, warehouse operations have significantly improved in efficiency.

- The number of workers decreased from 20 person to only 4 person by using only 30 Pcs robots.

- By using Geek+ solution, ACCA has also improved its brand image and become a renowned 3PL in Japan, attracting world renowned brands in their warehouse.

ALP introduces warehouse automation to solve its problem of limited resources

Geek+ AMRs help ALP reduce its picking labor by two thirds, improving space utilization of new storage layout by 20%.

The customer

Ally Logistic Property, Co., Ltd (ALP) is the first professional logistic property developer in Taiwan. With its award winning warehouse solution Logistics Republic, the Company aims to create a new generation of logistics facility, by developing the logistics network, integrating resources and implementing the latest technology equipment, providing a highly efficient industrial environment for major industries and logistics services providers.

The challenge

Faced with an increasing variety of SKUs but restricted quantities, ALP decided to implement warehouse automation to facilitate its operation.

Our solution

- Geek+ implemented its picking solution in a 5776 square meter warehouse covering 10,000 active SKUs, for an improved picking rate of 450 pieces per hour.

The Geek+ impact

- Significant warehouse operation improvement

- Implementation of Geek+ AMR reduced picking workforce by 2/3

- New layout helped enhance 20% of space utilization

- No. of racks: 800

- No. of workstation: 15 (putaway: 6, picking: 9)

- No. of robots applied: 70*P800

- Picking rate/hr: 450/hr

Empower teams up with Geek+ to build a fully automated logistics warehouse for clients

Geek+ flexible logistics solutions lead clients from convenience to agility.

The Customer

Empower is a new company which offers tailor-made logistics solutions for E-Commerce Industry. It is based in Hong Kong and it mainly caters needs for the client in the asia pacific (inc. XiaoHongShu and Globalegrow E-Commerce).

The Challenge

Develop an automated warehouse for mainland e-commerce client to increase its efficiency and meet peak requirement.

Our Solution

- Warehouse size: 1500 sqm; No. of workstation: 6+1

- No. of racks: 331* racks + 6* pallets; No. of robots applied: 15* P800

The Geek+ impact

- Combination of standard and simplified workstation to adapt picking process for both bin picking and pallet picking.

- The standard workstation is for piece picking while the simplified workstation is for large carton box picking only. Thus, forklift can directly pick the pallet at the simplified workstation to enhance the picking process.

Why did Dell choose Geek+’s picking solutions to upgrade its warehouse?

Geek+ innovatively integrated the rapid visual inventory feature in the ‘goods to person’ picking system, improving the inventory management.

The customer

Kerry Logistics is a third party logistics provider, warehouse operator and the oldest international freight services company in mainland China.

Dell is a multinational computer technology company that develops, repairs and supports computers and related products and services.

The challenge

Kerry Logistics manages and operates Dell’s Xiamen spare parts warehouse. The layout of the warehouse area is very compact, and the usage rate of the storage area is very high, which increases the difficulty of manual selection. The traditional manual picking efficiency cannot meet the timeliness of Dell’s outbound storage requirements.

Our solution

- Geek+ deployed 32 P500 picking robots and over 2,000 sets of shelves

- A dense storage method was implemented to meet high storage capacity and high space utilization requirements

- The solutions allows to manage massive SKUs and the solution is highly flexible, functions such as picking, loading, and inventory can be switched at any time according to business needs

The Geek+ impact

- Single package inventory efficiency multiplied by 10 with the integration of a fast visual inventory device

- Entirely open and unmanned process, optimizing space utilization

- The number of on-site operators has been reduced, and the timeliness and accuracy of the overall operation has been improved, saving labor and management costs

How does Bosideng easily deploy smart logistics?

Geek+ and Bosideng work together to reduce costs and increase efficiency.

The customer

Bosideng, founded in 1976, is the largest manufacturer of down jackets, operating the most advanced production equipment in China, and has over 20,000 employees. Bosideng down jackets are hugely popular in 72 countries, such as the United States, France, Italy, with more than 200 million people wearing them in the world.

The challenge

- In-store sales are growing rapidly, and manual picking has become a bottleneck

- Forklift quantity is overly large, resulting in high costs, and personnel management is difficult;

- Automation rate is low, operation error rate is high

Our solution

- Provide an innovative storage solution for the warehouse operation of the Bosideng warehouse. The seeding container is directly the shipping carton, which is transported to the station through the suspension chain; the seeding wall is of two-layer fluent type, and the back is directly connected with the conveyor line and transported to the packing station for packaging.

- Build a logistics information platform via the logistics information exchange and warning feedback between the functional modules (WMS, WCS, TMS)

- Phase 1 project area covered 5000 square meters, utilizing 116 P800 robots, 15 picking stations and 3 single point stations are deployed. The total design inventory of the whole warehouse is nearly 150000, involving more than 6000 SKUs.

- Phase 2 project area covered 20,000 square meters and utilized 200 sets of P800 robots.

The Geek+ impact

- Delivery capacity increased to 3500 pieces / hour

- Single point RF putaway, reduced site occupation

- Enabled multi batch and small batch store replenishment

- Saved over 10 units of forklifts and over 50 manual workers

- Difficulty of personnel management is reduced, and the operation accuracy is established at 100%