Featured Case Studies

Case Studies

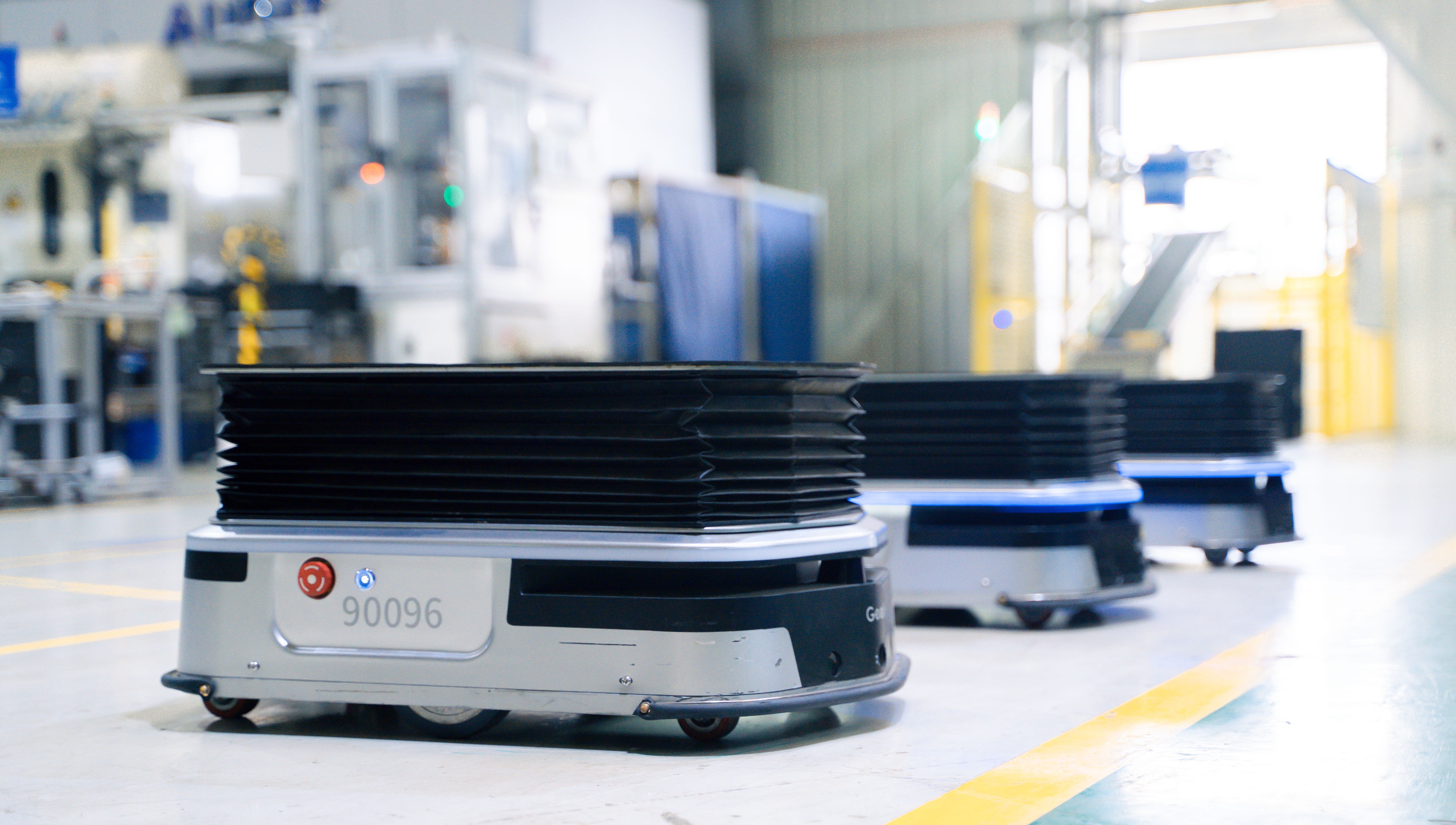

Geekplus

Recent Posts

Geek+ Helps ALPEN, Japanese Sporting Goods Retailer, Boost Picking Efficiency by 4 Times with Three Repurchases in Four Years

The customer

Started in 1972, ALPEN has become one of the major sports goods retailers in Japan through its integrated business model of production and sales. At present, ALPEN has 8 private brands such as TIGORA and IGNIO in Japan, and represents world famous sports brands such as NIKE and adidas, with nearly 400 chain stores.

The challenge

- Difficult to cope with the huge number of SKUs

- Insufficient workforce

- Fragmentation of orders

Our solution

P800

Customer value

- 4X improvement in shipment picking efficiency

- 50% reduction in ALPEN order fulfillment time

- Achieved multiple warehouse expansions

- Achieve rapid sales growth

- Develop sales strategies that peers can't

- Improve customer shopping experience and satisfaction

Italian 3PL Leader Life365 Enhances Multinational Cloud Deployment with High Speed and Intelligence

The customer

LIFE365 Italy S.P.A. provides customers with cutting-edge high-tech products and builds a bridge of commerce between Asia and Europe through import and export contracts with important manufacturers in China, Japan, Korea, Singapore and other countries..

The challenge

- Long walking distance for employees, efficiency to be improved

- New employees are not familiar with the site, high training costs

- Frequent order changes, operation flexibility to be improved

Our solution

Goods-to-person

M200C

Customer value

- Significant reduction in ineffective employee movement

- Increased picking efficiency

- Smoother field operations

- Accuracy rate increased to 99.99%

Handling Critical Supply Chain Challenges in the Pharmaceutical industry with Shelf-to-person solutions

About Customer

With over 25 years of experience in the local market, A&D Pharma is one of the largest pharmaceutical groups in Europe, offering pharmaceutical retail and drug distribution services, with a turnover of over 1 billion euros in 2021 and over 5000 employees.

A&D Pharma has two business lines, both of strategic importance: A drug distribution line and a pharmaceutical retail line.

About Partner

One of Europe’s leading chain of pharmacies, Dr.Max, recently upgraded their operations with a fleet of Geek+ shelf-to-person robots. Their distribution center in Bucharest, Romania, is now able to handle over 25 000 items a month with a picking accuracy rate of over 99%. The result is a new experience of shopping for medications for Dr.Max’s patients – the Hyper Pharmacy – where the experience goes beyond simply handing over a prescription and receiving medications.

The Challenge

-

The challenge posed by the growth of e-commerce businesses in recent years, as well as the demand of peak season.

-

Delivering products with a very strict best-before date in a faster and more accurate way. Customers need products from outbound operations to be shipped with the correct best-before date (Expiry date)

Our Solution

-

Dr. Max's distribution center in Bucharest (Romania) is operating currently with 96 P500 picking robots. The area in which the Geek+ shelf-to-person solutions operate is 3,200 m2, out of a total warehouse area of 4,830 m2.

-

Dr. Max is able to handle more than 25,000 SKUs per month thanks to Geek+'s warehouse automation. With 99.99% accuracy, Dr. Max is able to handle 180 - 190 lines/hour during peak seasons.

-

Dr. Max has become a gamechanger in the pharmaceutical industry by implementing these solutions. It has become one of the most powerful e-commerce players in Romania and has established a new way of shopping in pharmacies with a concept called Hyper Pharmacies.

The Geek+ impact

-

99.99% accuracy in packet classification

-

The warehouse supports more than 25,000 SKUs per month

-

96 P500 robots working 24/7

-

One of the most important e-commerce platforms in Romania

Geek+ and Körber Digitalize Ariat Supply Chain with Smart Robotics

About Customer

Ariat International, Inc. is a leading manufacturer of innovative performance equestrian footwear, apparel and belts. Featuring a patented technology designed to deliver stability, durability and comfort, Ariat pioneered the application of advanced athletic shoe technology into English riding boots and authentic Western boots, Ariat products are sold in a network of retail outlets throughout the world.

About Partner

Supply Chains are growing more complex by the day. Körber Supply Chain uniquely provides a broad range of proven, end-to-end supply chain solutions fitting any business size, strategy or appetite for growth. Capable of delivering not just software, but automation, voice, robotics, and materials handling - plus the expertise to tie it all together. We are a global partner not just for today, but also as the needs of supply chains continue to evolve.

The Challenge

- Labor Shortages created by the rise in demand

- Needing to optimize the warehouse and increase throughput

- Needing to reduce physical strain for associates

Our Solution

Geek+ worked collaboratively with Körber Supply Chain to optimize throughput and increase storage capacity in Ariat's 1 million sq. ft warehouse operations. Integrating with K. Motion Warehouse Advantage (WMS), 88 Geek+ picking robots and 2,000 racks helped Ariat to achieve greater operational speed and end-customer experience. After its initial order, Ariat expanded the solution with an additional 30 picking robots.

The Geek+ impact

- Improved picking efficiency, accuracy and throughput

- Decreased walking distance by 82% - from 40,000 steps a day to 7,000 steps a day

- Increased associates' productivity by 100%

- Faster and easier training process for associates

- Moral boosting - staff see automation as a way to support them, instead of replacing them

Decathlon Case Study - Europe E-commerce Logistics Upgrade

About Customer

Founded in France in 1976, Decathlon is a professional sports goods retailer specializing in the mass sports market, integrating the entire production chain of sports product design, R&D, production, branding, logistics, and retail. With over 1500 stores in 49 countries, it is the largest sporting goods retailer in the world.

The challenge

New customer expectations for e-commerce – higher volumes of orders and returns, same- and next-day delivery, and nearly perfect accuracy – have brought

new challenges for retailers and a need to address logistics bottlenecks. With 1045 stores in 25 European countries, Decathlon requires a highly flexible and fast supply chain and has turned to Geek+’s goods-to-person solutions to optimize its B2C logistics.

Our Solution

Geek+ tailor-made new robotics solutions for three distribution centers located in Castelnau, France,

Łódź, Poland, and Campania, Italy, use hundreds of P-series picking robots. Unlike traditional infrastructure, the AMR systems allow for flexible maintenance and modification without any interruption of service.

%20Geek+%20a%20transform%C3%A9%20les%20entrep%C3%B4ts%20chez%20D%C3%A9cathlon%20dans%20de%20multiples%20sites%20en%20Europe%20-%20YouTube-1.png?width=640&height=314&name=(2)%20Geek+%20a%20transform%C3%A9%20les%20entrep%C3%B4ts%20chez%20D%C3%A9cathlon%20dans%20de%20multiples%20sites%20en%20Europe%20-%20YouTube-1.png)

The Geek+ impact

-

Expansion of the online customer base across EU

-

Increase storage capacity by up to 30%

-

Increase picking efficiency: 250 order lines per hour per station

-

Increase putaway efficiency: 339 articles per hour per station

-

3x efficiency vs. manual operations

Geek+ solutions improved Verte's warehouse throughput by 4x

About Customer

Verte is an AI cloud-based supply platform provider that connects, unifies, and automates commerce operations, powering retailers to sell wherever their customers are and focus on scalable growth.

The challenge

- Complex requirements across multi-sellers

- Needing to implement faster throughput for better customer satisfaction

Our Solution

- After purchasing 45 picking robots initially, Verte asked Geek+ to scale the solution to 130 picking robots and 3,000 racks in Verte's 750,000 sqft. warehouse in Georgia. Geek+ solutions enabled Verte to achieve greater warehouse productivity and meet rising consumer expectations.

The Geek+ impact

- Scaled throughput 4x times

- Implemented in less than 3 months

- Improved inventory storage and picking efficiency for both inbound and outbound fulfillment

- During peak season, Verte received over 250,000 units on the first shift with fewer than 50 staff-hours and didn't miss a single inbound or outbound service level agreement (SLA).

Video

Pharmaceuticals Company builds supply chain resilience with Tote-to-Person picking

About Customer

Founded in 1999 and headquartered in Wuhan, China, the company is responsible for the distribution of pharmaceutical formulation, TCM and herbs, medical devices, APIs, and more. With a broad domestic distribution network, the company is considered one of China’s leading pharmaceutical companies.

The challenge

- Labor-intensive operations and unsafe work environment

- Strict safety regulations due to COVID-19

- Need for more storage capacity

- Demand for highly accurate operations

Our Solution

- Eight tote-picking RS-2 robots were deployed on a 500 sqm storage area

- Installation of robot compatible shelving, including 3000 totes

The Geek+ impact

- Storage capacity improved by 200%

- Picking efficiency improved by 300%

- Picking accuracy improved by 99.99%

- Improved work environment compatible with current safety regulations

-1.png)

Catch.com.au improves services with over 100 AMRs

About Customer

Catch.com.au is one of Australia’s leading online retailers. Founded in 2006, they aim to bring new e-commerce solutions to Australia and support online shoppers with a wide range of brands and products at low prices. Purchased by Westfarmers Group in June 2019, they experienced rapid business growth.

The challenge

- Low warehouse storage efficiency cannot meet regular storage demands

- Rapid surge in demand

- Rapidly growing customer base with 30,000 new customers every week

- High expectations for fast and accurate deliveries

Our Solution

- Over 100 picking robots were deployed in Catch.com.au’s 2,000 sqm facility to manage an inventory of 80,000 SKUs

The Geek+ impact

- The ability to quickly expand operations in line with growth

- Improved picking efficiency; picking rates up to 2000 items / h

- Increased throughput capacity and speed of delivery

Siemens Switchgear Use a Robot Army to Achieve a 350% Efficiency Leap

About Customer

Shanghai Siemens Switchgear is a core node in Siemens’s global supply chain, specializing in medium-voltage switchgear production. With a focus on innovation and lean digitalization, the company operates a state-of-the-art facility in Shanghai, China, and plays a pivotal role in Siemens’s global manufacturing strategy.

The Challenge

- Managing a vast, complex SKU portfolio.

- Manual operations limiting efficiency and response time.

- Space constraints hindering storage capacity.

- Implementing automation without disrupting production.

- No existing solutions for discrete manufacturing needs.

Our Solution

- Solution Deployed: End-to-end warehouse-to-production automation.

- Robotic Integration: 100+ robots, including P800, RS/C, X-series, and MP1000R.

- System Integration: Integrated with WMS, MES, and SAP for real-time data.

- Spatial Optimization: 60% footprint reduction, 300% storage increase.

.png?width=788&height=440&name=Untitled%20design%20(2).png)

The Geek+ impact

- Efficiency: 350% increase in operational efficiency.

- Accuracy: Near-perfect materials accuracy on the production line.

- Storage Utilization: 300% increase in site storage capacity.

- Safety: Human-centered design with advanced safety systems and ergonomic improvements.

Video

ASDA launches UKs first national sortation project

About Customer

Asda Logistics Services is a hub of activity, with 39 nationwide distribution operations including 21 food depots, three clothing centers, two ambient GM hubs, two import centers, two dot.com fulfillment centers, and nine ASCs. Supporting distribution across five types of store formats as well as the delivery of parcels to customers’ homes and to store for Click and Collect, Asda Logistics Services distributes an estimated 800,000 deliveries to store and 20,000,000 deliveries to customers a year.

The challenge

- More customers shopping online, followed by surges in forward and reversed volume

- Boost Asda’s toyou e-commerce service to better serve customers

- Respond to fluctuating order volumes without having to invest in additional warehouse space.

Our Solution

- 60 Geek+ S20C robots were deployed on a sorting area of 360 sqm in Asda’s cross-docking facility.

Video

Geek+ M100 robots streamline Yanfeng’s manufacturing process

The Customer

Yanfeng is a world leader in automotive interiors focused on product development, system integration, and design. Since 2010, Yanfeng has expanded its global presence and is currently operating over 230 factories worldwide with over 65,000 employees, and 6,700 employees dedicated to development and design. By providing the automotive industry with first-class products and services, Yanfeng aims to redefine the way people relax, work and play inside their vehicles.

The Challenge

- Low efficiency of moving materials to production line

- Difficulties managing inventory

- Long material transportation path

- Labor-intensive operations due to frequent manual transfer of materials

- Difficulties visualizing the manufacturing flow and high error rates

Our Solution

- Geek+ provides Yanfeng with moving robots M100 for transferring raw materials to production lines

- Connecting Geek+ Moving System (GMS) to WMS and MES, enabling real-time visibility of the manufacturing process

The Geek+ impact

- Reduced labor costs

- 99% Material handling accuracy

- Real-time monitoring of manufacturing process

Video

Konica Minolta streamlines manufacturing process with both picking and moving solutions

The customer

Konica Minolta is a Japanese multinational technology company headquartered in Tokyo, with offices in 49 countries worldwide. The company manufactures business and industrial imaging products, including copiers, laser printers, multi-functional peripherals (MFPs) and digital print systems for the production printing market.

The challenge

- Konica was looking for an AMR solution to achieve higher accuracy of materials handling in its warehouse and replace its magnetic stripe AGVs which offer little flexibility, are subject to low operating efficiency, and lead to high maintenance costs.

- Production line consists of more than 30,000 different materials, it is costly to manage the inventory and accuracy.

- High frequency of material delivery, low efficiency of manual material delivery, poor timeliness, and high labor-intensity.

Our solution

- 10 P800 robots in the warehouse and make use of Geek+ iWMS , for precise management of materials

- 3 M100 robots featuring SLAM navigation at the production line to deliver the materials from warehouse to production line

- Geek+ Moving System (GMS) receives task from iWMS and deliver the materials to production line automatically.

The Geek+ impact

- Improved inventory accuracy

- Stock-taking frequency reduced by 92%

- Material delivery efficiency increased by 31~42%

- Storage area saved by more than 32%

- Reduced labor intensity

Video

%20(1)-1.png)

.png)

.png)

.png)