Featured Case Studies

Case Studies

Siemens Switchgear Use a Robot Army to Achieve a 350% Efficiency Leap

About Customer

Shanghai Siemens Switchgear is a core node in Siemens’s global supply chain, specializing in medium-voltage switchgear production. With a focus on innovation and lean digitalization, the company operates a state-of-the-art facility in Shanghai, China, and plays a pivotal role in Siemens’s global manufacturing strategy.

The Challenge

- Managing a vast, complex SKU portfolio.

- Manual operations limiting efficiency and response time.

- Space constraints hindering storage capacity.

- Implementing automation without disrupting production.

- No existing solutions for discrete manufacturing needs.

Our Solution

- Solution Deployed: End-to-end warehouse-to-production automation.

- Robotic Integration: 100+ robots, including P800, RS/C, X-series, and MP1000R.

- System Integration: Integrated with WMS, MES, and SAP for real-time data.

- Spatial Optimization: 60% footprint reduction, 300% storage increase.

.png?width=788&height=440&name=Untitled%20design%20(2).png)

The Geek+ impact

- Efficiency: 350% increase in operational efficiency.

- Accuracy: Near-perfect materials accuracy on the production line.

- Storage Utilization: 300% increase in site storage capacity.

- Safety: Human-centered design with advanced safety systems and ergonomic improvements.

Video

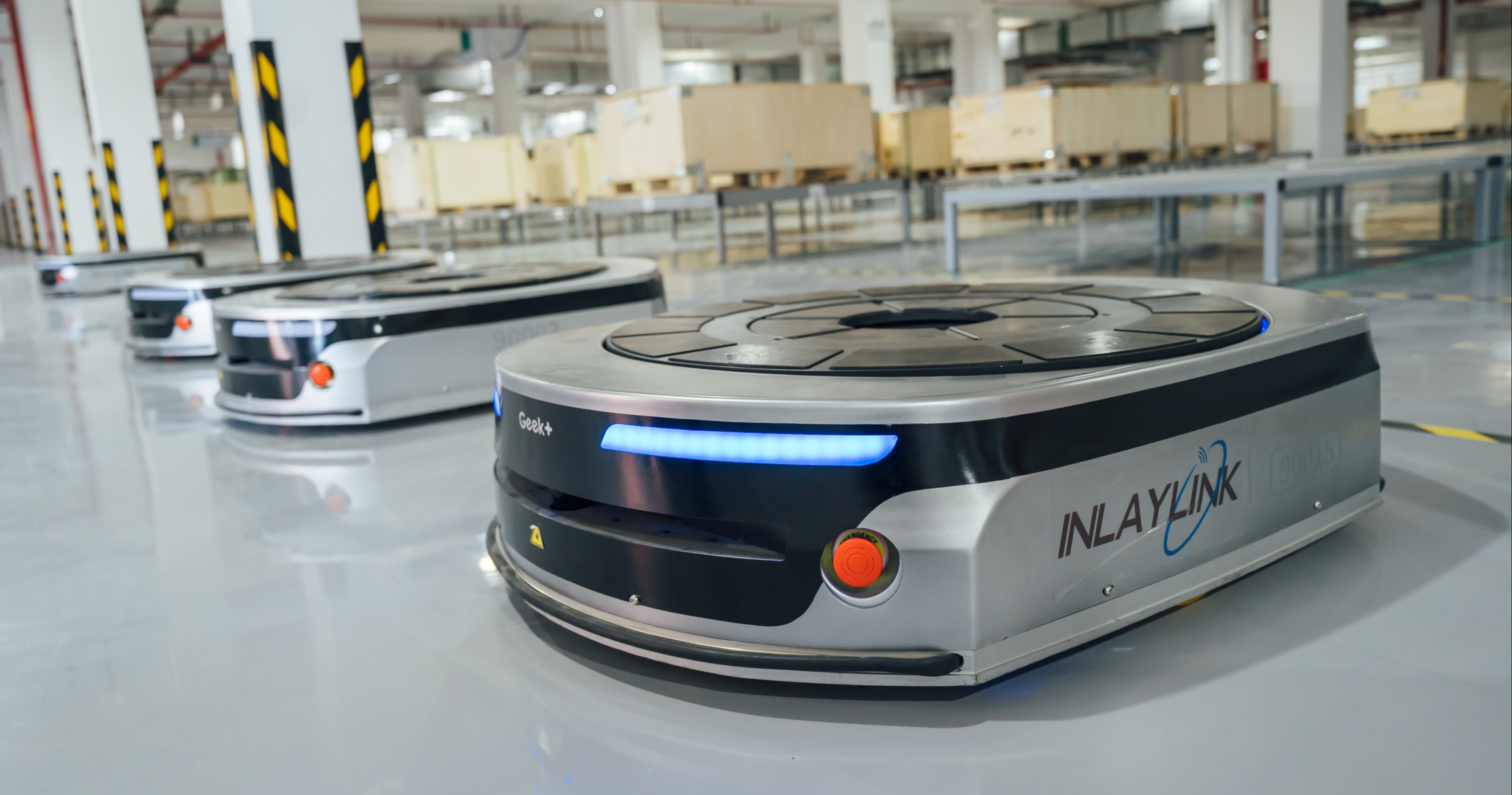

INLAYLINK factory realizes a smart upgrade with moving robots

The Customer

INLAYLINK is one of the world-renowned manufacturers of RFID tag antennas, specializing in the design, research and development, production, and sales of RFID tag antennas. It is also one of the few high-tech companies that can provide RFID data collection solutions and has won many world-known rewards.

The Challenge

- On-site materials are moved across floors and multiple areas frequently, and manual handling cannot guarantee the timeliness

- Manual handling is labor-intensive

- The value of a single material on-site is high. Checking, verification, signing, and handover are required for the delivery, online, offline, and warehousing links.

- The efficiency is low and the management cost is high.

- An information system is required to connect the warehouse and the production line to achieve physical and automatic docking of accounts.

Our Solution

- The site is equipped with 12 M1000 robots that transfers the materials out of the warehouse and sends them to the production lines.

- The robots are connected with vertical warehouse stackers, elevators, access control, and other systems to realize automatic, accurate, and timely distribution of materials across floors and sectors.

- The Geek+ Moving System (GMS) is connected to WMS and MES, enabling real-time visibility of the manufacturing process.

The Geek+ impact

- The integration information allowed a reduction in material management costs by 60%

- Material handling efficiency increased by 30%

- Reduced labor-insensitive operations

Video

.png)