Featured Case Studies

Case Studies

-1.png?width=374&height=135&name=images%20(1)-1.png)

Infios and Geekplus drive efficiency in hardware manufacturing industry at Deutsche Telekom

The Customer

-

One of the world's leading integrated telecommunications companies: more than 261 million mobile customers, 25 million fixed-network lines, and 22 million broadband customers.

-

Deutsche Telekom is present in more than 50 countries. With a staff of some 200,000 employees throughout the world, generated revenue of 115.6 billion Euros in the 2024 financial year.

-

The B2B hardware distribution hub, supplying branches and enterprise customers. It manages 2,200 SKUs with a total stock of 2.5 million units.

The Challenge

- Digitalize B2B hardware logistics to improve efficiency, scalability, and working conditions.

- Reduce unnecessary walking and repetitive manual tasks in inbound and outbound processes.

- Replace outdated logistics technology after only 18 months of planning and development.

Our Solution

As general contractor, Infios deployed an integrated software and robotics solution, centered on the Geekplus Shelf-To-Person P1200 system.

-

- Autonomous Mobile Robots (AMRs) transport shelves of up to 1,200 kg directly to picking and packing stations.

- Manual walking is eliminated, while put-to-light and pick-to-light systems ensure accuracy in order fulfillment.

- Designed throughput: 30 inbound positions per hour and 100 outbound positions per hour, with easy scalability by adding robots or stations.

- All logistics flows are orchestrated by the Infios Unified Control System (UCS), seamlessly integrated into Deutsche Telekom’s IT landscape..

The Geekplus impact

Through Geek+ technology, Infios successfully transformed the Hanover distribution center:

- Operational efficiency: Significant improvement in inbound and outbound speed with minimized human error.

- Workplace ergonomics and safety: Staff relieved from monotonous and physically demanding tasks, improving conditions and reducing risks.

- Scalability and adaptability: Modular and compact solution that can be scaled to meet growing demand with minimal effort.

- Modernization of logistics: Complete replacement of outdated technology with a future-proof, automated system.

Geek+ Opens Innovation Center to Revolutionize Warehouse Automation in North America

![]()

The Customer

Outdoor Network, a major U.S. distributor of vehicles and OEM parts, faced critical operational challenges, including consolidating multi-line orders across two facilities, labor shortages, and the need to enhance efficiency to meet peak-season demands. Partnering with Geek+ and KPI Solutions, Outdoor Network deployed innovative mobile robotic solutions at their East Coast Distribution Center in Albany, Georgia.

The Challenge

Outdoor Network encountered multiple hurdles in its warehouse operations:

- The need to consolidate multi-line orders from two separate facilities.

- Ongoing labor shortages due to heightened demand for their products.

- A pressing requirement to enhance operational efficiency to cope with peak demands.

These challenges hindered Outdoor Network's ability to maintain high service levels and operational agility, demanding a scalable and efficient solution.

Our Solution

Geek+ and KPI Solutions collaborated to design and implement an advanced automation strategy tailored to Outdoor Network’s needs:

- Integration of Mobile Robotic Solutions: Mobile robots were deployed to handle oversized items, efficiently managing putaway to static shelving and pallet racks.

- Streamlined Picking Operations: Robots transported oversized picks in carts to a dedicated consolidation area for outbound shipping.

- Optimized Single Facility Approach: By merging storage and picking processes into one consolidated facility, operations were simplified and streamlined.

This solution leveraged smart automation to boost storage capacity and efficiency while addressing labor challenges through reduced dependency on manual tasks.

The Geekplus impact

The collaboration between Ariat, Geek+, and Körber yielded impressive results that transformed Ariat’s supply chain operations:

- Improved Efficiency: Warehouse picking efficiency and accuracy experienced significant enhancements, directly impacting speed and reducing errors.

- Associate Productivity Advance: Productivity doubled, with a 100% increase noted following the implementation.

- Reduced Walking Strain on Associates: Associate walking decreased by 82%, minimizing workplace fatigue and improving employee satisfaction.

- Compliance with Demand Surges: The scalability of Geek+’s robots ensured Ariat could effectively meet demand spikes without operational bottlenecks.

Video

Geek+ and K&V Elektro Modernize Distribution with Shelf-to-Person Robotics

The Customer

K&V Elektro is a prominent distributor of electrical installation materials in the Czech Republic. Known for its modern approach to logistics and emphasis on operational efficiency, the company serves a wide range of customers with a constantly expanding product portfolio. To maintain its competitive edge and meet growing customer demands, K&V Elektro sought to modernize its distribution infrastructure with advanced automation.

The Challenge

K&V Elektro needed to address several key challenges to improve its warehouse operations:

- Increase warehouse capacity to store more than 14,000 SKUs.

- Speed up the order picking process to handle up to 7,700 lines/day.

- Automate goods handling operations to reduce reliance on manual labor.

- Improve picking accuracy and operational safety.

- Optimize the use of storage space.

- Seamlessly integrate with the company’s existing SAP ERP system.

These challenges were compounded by a long-term shortage of human resources in the labor market, making automation a critical priority.

Our Solution

Geek+ implemented a Shelf-to-Person robotic warehouse system tailored to K&V Elektro’s needs. The solution included:

-

Racking System:

Shelving racks 2.8 m high with 6 shelves per rack, each capable of holding up to 1,000 kg. The design allowed transport robots to pass under the first shelf for efficient operations. -

25x Geek+ Mobile Robots:

The warehouse was equipped with 25 Geek+ P800 transport AMR robots, which transported racks to inbound and outbound stations. The robots navigated using QR codes on the floor, ensuring precise and efficient movement. -

Inbound Workstations:

Two inbound workstations were used for placing goods on racks. Once goods were confirmed, robots transported the racks to designated storage locations. The receiving capacity was up to 153 items per hour. -

Outbound Workstations:

Three outbound workstations were equipped with Put-to-Wall racks and Pick-to-Light technology. Operators were guided by panels displaying item details, optical pointers, and other tools to ensure accuracy. The system achieved a daily picking performance of 6,020 order lines, with a peak capacity of 7,700 lines/day.

The Geekplus impact

The implementation of Geek+ robotics brought significant improvements to K&V Elektro’s operations:

- Increased Throughput: Enhanced warehouse capacity and daily picking performance, with up to 7,700 lines/day during seasonal peaks.

- Improved Accuracy: Automation minimized errors in goods storage and picking.

- Labor Optimization: Reduced dependency on manual labor, addressing workforce shortages.

- Operational Flexibility: The system easily adapted to fluctuations in demand, such as seasonal peaks.

- Enhanced Transparency: Integration with SAP BW enabled accurate monitoring of performance and deviations.

- Optimized Space Utilization: Efficient use of available warehouse space supported K&V Elektro’s modernization strategy.

Video

Geek+ and TAHUHU Revolutionize Cold Chain Logistics with SkyCube Automation

The Customer

The Customer

TAHUHU is a leading cold-chain logistics provider supporting industries such as frozen food, fresh produce, dairy, and retail. Known for its unwavering commitment to quality and reliability, TAHUHU operates across multiple temperature-controlled zones, ensuring fast and safe delivery of sensitive products while maintaining customer satisfaction.

The Challenge

Cold-chain logistics presents unique difficulties, requiring precision, efficiency, and resilience to harsh conditions. TAHUHU faced three significant challenges:

- Labor Strain: Employees struggled to meet operational demands in low-temperature environments.

- Rising Delivery Pressures: Growing customer demand required faster fulfillment and streamlined processes.

- Operational Precision: Maintaining absolute accuracy and compliance was crucial to prevent costly errors in a highly sensitive supply chain.

Our Solution

Geek+ implemented its SkyCube pallet-to-person solution, specifically engineered for the needs of low-temperature warehouses like those operated by TAHUHU. This groundbreaking system transformed TAHUHU’s logistics processes across three controlled temperature zones (-25°C to 4°C).

- Cold Store AMRs: Automated mobile robots capable of operating in extreme low temperatures, ensuring efficient and continuous movement of pallets.

- Low-Temperature 4-Way Shuttle Trucks: Advanced vehicles designed to transport goods across storage locations, providing precise control and scalability.

- Automated Goods-to-Person Stations: Human-friendly workstations facilitated accurate order picking in a temperature-controlled environment.

- Temperature-Controlled Loading Docks: Seamlessly integrated docking systems expedited loading while maintaining strict temperature integrity.

These innovative technologies enhanced every stage of the cold-chain process, from optimized storage to last-mile delivery.

The Geekplus impact

The implementation of Geek+ SkyCube technology delivered measurable and unrivaled results for TAHUHU. Over a two-year performance survey, the solution exceeded expectations, achieving a remarkable 100% satisfaction rate across 68 operational criteria.

- 60% Manpower Reduction: Automation relieved employees from physically demanding and time-intensive tasks, significantly reducing labor dependency.

- 30% Increase in Storage Capacity: Optimized use of storage spaces allowed TAHUHU to accommodate a higher volume of products.

- 24/7 Operations: Automated systems enabled continuous operation, ensuring that TAHUHU could meet customer demands even during peak hours.

- Real-Time Tracking and Analytics: Digital transformation through real-time data monitoring improved decision-making and operational transparency.

- Enhanced Customer Satisfaction: Faster deliveries and consistent product quality solidified TAHUHU’s reputation as a trusted logistics provider.

TAHUHU’s upgraded cold-chain logistics are now safer, faster, and more efficient than ever, setting new benchmarks for the industry.

From TAHUHU’s feedback, they shared:

"Our CSA (Cold Chain, System, Automation) solution, in partnership with Geekplus, has completely revolutionized the way we operate. From pick-up to warehousing, order management, transportation, and delivery, Geekplus ensures low-temperature preservation across all processes. Managing three temperature zones is no longer a challenge thanks to Geekplus seamless technology integration."

Video

X5 Retail Group and Geek+: Revolutionizing Retail Logistics with Smart Sorting Systems

The Customer

- X5 Retail Group stands as one of the largest and most innovative retail companies in Russia, with a prominent presence across the country's expansive consumer market. Founded in 2006, the group has grown rapidly, earning a reputation for its diverse retail formats, cutting-edge technology adoption, and customer-first strategies that cater to millions daily.

Video

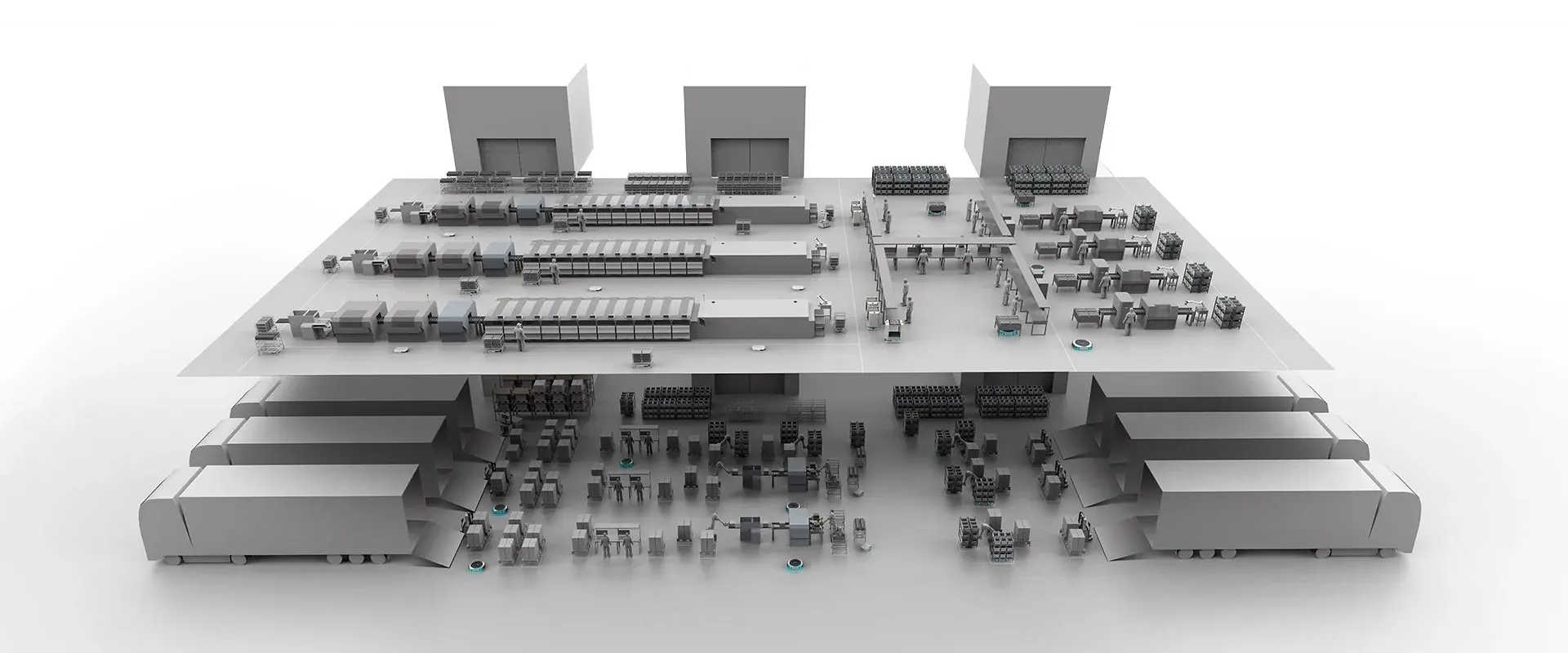

Geek+ Smart Factory: Setting a New Standard for Automated, Efficient Manufacturing

The Customer

The Geek+ Smart Factory system is at the forefront of manufacturing automation. Its AMRs connect diverse production scenarios, transforming traditionally static operations into dynamic and agile processes. Smart Factory solutions are designed to meet the diverse needs of global manufacturing facilities, enabling operations in industries ranging from electronics to automotive.

The Challenge

Manufacturers face significant challenges in today’s competitive landscape:

- Production Bottlenecks: Aging conveyor-based systems limit operational flexibility and struggle to keep up with growing production demands.

- Complex Product Portfolios: Managing multi-category production lines requires adaptable and scalable processes.

- Inefficient Resource Utilization: High costs and waste often stem from outdated systems and lack of operational visibility.

- Demands for Exceptional Quality: Clients increasingly expect high product quality and manufacturing traceability.

Our Solution

The Geek+ Smart Factory system delivers an end-to-end automation solution, transforming manufacturing sites into fully digitalized, streamlined operations.

- Advanced AMR Deployment: AMRs replace traditional conveyor systems, introducing flexible, decentralized production “islands” for greater agility than linear workflows. Deployment is carried out in strategic phases to ensure uninterrupted production, optimize robotic placement for workflow efficiency, address bottlenecks, and ultimately enable factories to double their production capacity.

- IoT and 5G Connectivity: Industrial IoT and 5G are leveraged for real-time data transmission and synchronization across the manufacturing floor, supporting precise initiation, tracking, and reporting of tasks.

- Edge Computing and MES Integration: Manufacturing Execution Systems (MES) combined with edge computing allow real-time control, seamless machine-to-machine communication, and detailed production oversight. Each implementation is customized to the client's unique industrial requirements.

- 3D Vision Technology: All AMRs feature advanced 3D vision systems, supporting autonomous navigation, object recognition, and manipulation, even in the most complex, multi-product environments.

The Geekplus impact

The Geek+ Smart Factory system delivers a comprehensive automation solution that transforms manufacturing sites into digital, streamlined operations with minimal disruption and clear, measurable gains.

- Efficiency Gains: Single-shift production efficiency increases by 33% to 67%, with reduced idle time and minimized production waste.

- Superior Quality Control: Assembly pass rates exceed 98%, ensuring products are delivered with consistent, exceptional quality.

- Cost Reduction: Material traceability reaches up to 95%, improving inventory management and reducing operational expenses.

- Versatility and Scalability: The system easily manages multi-category production lines and scales rapidly to suit urgent or high-volume orders.

Video

Geek+ and Assurant Elevate Risk Management with Robotics Solutions

The Customer

Assurant, a global leader in risk management solutions, specializes in protecting consumer goods and ensuring seamless customer experiences. With its deep expertise and innovative strategies, Assurant has set the standard for safeguarding assets and enhancing operational efficiency. By integrating advanced technologies into its processes, Assurant continues to redefine how businesses mitigate risk and deliver value to their customers.

Video

Geek+ and Hessing Revolutionize Food Logistics with Robotics

The Customer

Hessing Supervers has been a trusted name in fresh produce processing for over 50 years. Specializing in ready-to-cook vegetables, processed fruits, and meal salads, Hessing supplies retail chains, fast-food outlets, and inflight caterers across the Netherlands, Belgium, Germany, and Denmark. Handling millions of packages weekly, the company sought to modernize operations to keep pace with growing demand and maintain its commitment to freshness and quality.

The Challenge

Operating in the highly competitive fresh food market, Hessing faced several operational challenges:

- Complex Workflow Management: Their Greenport Venlo site required seamless coordination across washing, mixing, and packaging zones.

- Time Sensitivity: With fresh produce having limited shelf life, delays in processing and distribution could lead to increased food waste and cost inefficiencies.

- Scalability Needs: Rising demand for pre-packaged fruits and vegetables necessitated a logistics solution capable of efficient scaling.

- Employee Safety and Productivity: Managing a three-story facility posed increased risks and physical demands on employees.

Our Solution

Hessing turned to Geek+ to implement a state-of-the-art logistics system designed to meet these challenges head-on. Key features of the solution included:

- 112 Geek+ M200 Robots: These autonomous mobile robots connected distinct processing areas and ensured seamless movement of goods across floors.

- AI-Driven Fleet Management: Utilizing advanced algorithms, the central AI monitored hundreds of robots simultaneously to optimize routes, reduce traffic congestion, and ensure peak performance.

- 3D Obstacle Detection: Robots were equipped with sensors to identify and safely bypass obstacles, maintaining the highest safety standards for employees and products.

- Three-Story Operation Integration: The AMRs operated on multiple levels, ensuring end-to-end coverage of the distribution process while optimizing vertical space utilization.

- Streamlined Food Processing Workflow: The system enabled faster transitions between washing, mixing, and packaging stations, minimizing hold-ups and preserving the freshness of produce.

The Geekplus impact

The new system delivered outstanding results for Hessing, including:

- Efficiency Gains: Robots transformed workflow efficiency, enabling faster processing times and timely produce delivery.

- Reduced Food Waste: The intelligence-driven logistics minimized delays, ensuring higher percentages of products reached consumers in peak condition.

- Fresher Produce: Accelerated movements through the supply chain enabled retailers to enjoy longer product shelf lives.

- Enhanced Safety and Productivity: Employees reported improved working conditions due to reduced physical strain and optimized facility operations.

- Scaled Operations: The innovative system positioned Hessing to expand its operations in response to rising demand without adding logistical bottlenecks.

“By automating our distribution center with Geek+’s moving solutions, we’ve made our ‘factory of the future’ vision a reality. We now bring healthier food to consumers faster and with less waste—an achievement we are truly proud of.”

Hans Hessing, Director Center of Excellence, Hessing Supervers

Video

Geek+ and Systemex Automation Partner to Revolutionize Robotics in North America

The Customer

Systemex Automation is a leading Canadian systems integrator specializing in the engineering, manufacturing, and integration of advanced automation solutions for diverse industries. With a vision to deliver innovative robotics to its manufacturing, distribution, and retail customers across North America, Systemex Automation partnered with Geek+ to access a world-class autonomous mobile robot (AMR) portfolio and enhance its capabilities as a trusted solutions provider.

The Challenge

- Escalating labor shortages were causing operational bottlenecks and limiting growth potential for Systemex Automation's clients.

- Rising operational costs placed additional pressure on margins, demanding more efficient processes.

- Diverse customer needs for scalable, flexible automation tailored to existing warehouse workflows complicated solution design.

- The need to quickly adapt to changing order volumes and market dynamics called for future-proof, easily integrated robotics.

Our Solution

Geek+ and Systemex Automation worked together to deliver a comprehensive response to these industry demands:

- Integrated AMR Portfolio: Geek+ supplied Systemex Automation with an extensive range of AMR solutions, including picking, moving, sorting, and storage/ASRS systems, to tackle all stages of warehouse logistics.

- Seamless Deployment: Systemex Automation leveraged its systems integration expertise to ensure smooth implementation of Geek+ robotics, enabling minimal disruption and maximum compatibility with existing operations.

- Tailored Rollouts and Training: Joint planning allowed phased deployments based on client-specific needs, with collaborative training programs preparing staff to efficiently manage new robotic systems.

- Continuous Support: Ongoing assistance from both partners guaranteed successful adoption and long-term reliability for customers.

The Geekplus impact

Systemex Automation’s partnership with Geek+ has delivered transformative benefits to its client base:

- Boosted Operational Efficiency: Automated solutions have streamlined warehouse workflows, elevating accuracy and reducing order fulfillment times.

- Reduced Operating Costs: Reliance on manual labor decreased, while workplace inefficiencies were minimized, resulting in measurable savings.

- Alleviated Labor Constraints: Robotics have enabled customers to scale rapidly and adapt to labor market fluctuations, driving competitive advantage.

- Scalable Flexibility: The modular AMR solutions allow seamless expansion and customization as business needs evolve.

Video

Geek+ and China Post Revolutionize Logistics with Smart Sorting Technology

The Customer

China Post is a leading logistics enterprise in China, known for its extensive delivery network and capacity to handle massive volumes of parcels daily. To maintain its competitive edge and support the rapid growth of e-commerce and express logistics, China Post sought innovative, scalable solutions to boost productivity and automation in its processing centers.

The Challenge

- The growing volume of parcels presented a significant challenge in terms of space, speed, and efficiency in sorting operations.

- High labor costs and reliance on manual processes limited scalability and efficiency.

- Intense logistics pressure during shopping festivals such as 618 and Double 11 required the ability to handle extreme peak demand efficiently.

- The need for a unified system that could simultaneously manage large and small parcels effectively.

Our Solution

Geek+ collaborated with China Post to design and implement a smart sorting system at the Wuhan Processing Center. Key elements of the solution included:

- Belt Sorting Robots: Geek+ deployed belt sorting robots tailored for express logistics and postal scenarios, capable of managing returns, order sorting, and package distribution.

- Modular Coordination: A three-dimensional modular design ensured seamless operations between automated systems across the facility.

- High-Volume Capacity: 320 robots were deployed, covering 5,000 square meters of operational space, enabling simultaneous sorting of large and small parcels.

- Smart Scheduling: Intelligent algorithms optimized robot dispatch, reduced congestion, and ensured smooth, efficient operations.

- Simplified Integration: The system was designed for quick deployment and required minimal maintenance.

The Geekplus impact

The implementation of Geek+'s AGV sorting technology delivered outstanding results for China Post:

- 60% Efficiency Improvement: Daily processing capacity reached over 600,000 parcels, meeting the demands of peak periods with ease.

- Enhanced Sorting Accuracy: High operational stability ensured a substantial reduction in sorting errors, enhancing customer satisfaction.

- Cost Reduction: Low-cost, easily maintained solutions minimized operational expenses.

- Streamlined Operations: Unified automation for large and small parcels ensured smooth handling and maximized facility throughput.

- Global Scalability: The system has been replicated successfully across other facilities, demonstrating its robustness and adaptability.

Video

NEXT and Geek+: Transforming Retail Operations with Autonomous Robotics

The Customer

NEXT is a leading UK retailer specializing in clothing, footwear, and home products. With over 700 stores, including 500 in the UK and around 200 across Europe, Asia, and the Middle East, NEXT serves millions of customers annually. A member of the FTSE 100 index, the publicly traded company is recognized for its innovative approach to e-commerce and customer-focused retail solutions.

The Challenge

The fashion industry often experiences dynamic demand cycles and NEXT faced several key operational challenges in keeping up with growing customer expectations:

- Demand Volatility: Customer orders surged unpredictably, creating strain on supply chain operations.

- Manual Process Limitations: Traditional workflows delayed order handling and fulfillment, making it challenging to maintain operational efficiency.

- Delivery Speed Requirements: Rapid same-day and next-day fulfillment became critical during high-demand periods such as sales and promotions.

- Scalability: NEXT required a flexible and future-proof system to efficiently handle growing business demands.

Our Solution

Geek+ deployed a comprehensive robotics solution tailored to NEXT’s operational needs, including the following components:

- Fleet of 250 AMR Robots: The robots enabled seamless automated workflows, managing sorting and picking operations with maximum precision and efficiency.

- Sorting and Picking Automation: Integrated sorting and picking systems streamlined the entire order fulfillment process, from inventory handling to delivery preparation.

- Advanced Robotics Technology: Real-time AI-driven algorithms optimized operations, streamlining inventory placement and retrieval to reduce delays.

- Scalable Design: The system was designed to adapt to NEXT’s evolving needs, allowing for seamless expansion during peak demand or future business growth.

The Geekplus impact

NEXT experienced substantial benefits following the integration of Geek+ AMR robots and automated systems:

- Enhanced Productivity: Warehouse operations saw a 2x boost in efficiency compared to previous manual processes.

- High Order Volumes: NEXT successfully processed over 16,000 products daily, meeting customer demands reliably.

- Same-Day Fulfillment: Automation supported rapid and accurate deliveries, even during peak sales periods.

- Seamless Scalability: The flexible architecture enabled NEXT to manage growing inventory volumes and future-proof its warehouse operations for continued expansion.

Video

Starlinks and Geek+ Transform E-commerce Logistics in Saudi Arabia

The Customer

Starlinks is a prominent logistics and supply chain solutions provider based in Saudi Arabia. The rapid growth of e-commerce within the region saw online sales surge from 6% to 23% in recent years, pushing Starlinks to adapt to the market's evolving logistics requirements. Known for delivering innovative and efficient logistics services, Starlinks sought a robust automated solution to handle increasing order volumes while maintaining a high level of customer satisfaction.

The Challenge

Starlinks faced several operational hurdles as they sought to meet the demand of a booming e-commerce landscape:

- High Storage and Flexibility Needs: Managing an extensive catalog of SKUs while maintaining the ability to scale operations as demand fluctuated.

- Labor Challenges: Addressing recruitment and workforce constraints by designing a system that reduced dependency on manual labor.

- Order Processing Efficiency: Ensuring fast and accurate order handling to enhance the customer experience and maintain competitiveness.

Our Solution

To address these challenges, Starlinks partnered with Geek+ to implement a comprehensive automation solution comprising:

- Goods-to-Tote RoboShuttle: This system enabled double-deep storage, supporting 12 million items, and effectively managed extensive SKU requirements.

- Intelligent Sorting System: Using Geek+ proprietary algorithms and smart technologies, the solution streamlined the flow of goods from inbound to sorting and outbound operations.

- Ergonomic and User-Friendly Design: The system prioritized employee comfort and health, integrating ergonomic workflows and easy-to-navigate interfaces that required minimal training.

- Advanced Scheduling and Coordination: Multiple robots worked collaboratively to ensure seamless picking, sorting, and replenishment operations.

The Geekplus impact

The deployment of Geek+ solutions delivered significant value to Starlinks across key performance indicators:

- Scalable Storage: Double-deep storage capacity met peak demand requirements, housing up to 12 million items while maintaining quick access to high-mix SKUs.

- Improved Workforce Efficiency: With ergonomic design and simplified workflows, employees experienced a comfortable and productive working environment, reducing labor-intensive tasks.

- Enhanced Accuracy and Speed: Geek+ intelligent systems enabled rapid and precise order processing, ensuring customer satisfaction through timely deliveries.

- Operational Efficiency: Streamlined workflows maximized throughput while the intelligent sorting and picking systems minimized errors.

- Future Expansion Capability: The automation system provided the flexibility needed to meet future business growth and fluctuating market demands seamlessly.

" Our new solution comprises a pallet storage and handling storage system, a manual pick tower as well as a robotics solution allowing us to cater to a wide range of customer requirements and operations complemented by micro fulfilment centres distributed strategically across Saudi Arabia. Advanced automation and big data analytics enable us to better track and manage inventory, predict demand, and optimize routes for transportation thus helping us to increase efficiency, reduce operating costs and provide seamless services to our customers. We are committed to driving further innovation in the logistics and supply chain industry in the region and reducing lead time to e-commerce shoppers."

Salah Taha, Director of Operations at Starlinks

Video

-1.png?width=169&height=61&name=images%20(1)-1.png)

-1.jpg?width=200&height=66&name=Hessing%20Corporate%20SV%20logo%2070cm(1)-1.jpg)