Featured Case Studies

Case Studies

Maximizing vertical space for one of the biggest Europe's pharmacy group

The Customer

-

Leading pharmacy chain in Europe with 210+ locations in Italy.

-

Expanded in 2023 with the acquisition of Neo Apotek SpA.

-

Centralized services in 2024 with the 14,000 sqm automated warehouse in Telgate to strengthen omnichannel capabilities and e-commerce.

-

Operates with over 20,000 employees, 3,000 pharmacies, and services across 17 European countries.

The Challenge

- Dr. Max aimed to redefine pharmacies with a clear, distinctive message while serving as a health reference point for local communities.

- Required an efficient solution for order fulfillment in warehouses in their huge network across Czech Republic, Romania, and Italy, including their 14,000 sqm warehouse in Telgate, Bergamo.

Our Solution

- Geek+ implemented Goods-to-Person solutions featuring:

- 8-meter-high RoboShuttle robots for vertical storage.

- P40 Fulfillment robots for fast, accurate picking.

- Manages 11,000+ units for e-commerce and retail.

- Collaboration with SSI Schaefer enabled quick system implementation and integration.The system supports e-commerce and retail deliveries for Italian clients and pharmacies.

The Geekplus impact

Geekplus's flexible, reliable and scalable solutions help Dr. Max to manage market changes with ease and to achieve Business Objectives.

- 3–4x efficiency improvement over manual operations.

- Achieved 99.99% accuracy in order fulfillment.

- Quick implementation completed within 1–3 months.

- Flexible, scalable solutions enable Dr. Max to easily adapt to market changes.

Geekplus Powers Happy Returns's Next-Generation Reverse Logistics Operations

The Challenge

Happy Returns, a reverse logistics company for online retailers to manage product returns, sought an automation solution to enhance the efficiency of their returns process, simplify operations for Return Hub specialists, and provide faster, more accurate service to their retailer and merchant customers.

Our Solution

Geekplus transformed Happy Returns’s 91,500 sq. ft return hub in eastern Pennsylvania by deploying 150 advanced sorting robots. This automation streamlined Happy Return's returns process into a fast and seamless operation, significantly boosting warehouse turnaround times while creating a safer and better working environment. Building on the initial implementation in Pennsylvania, Happy Returns is expanding Geekplus robotics solutions to two additional facilities across their Return Hub network.

The Geekplus impact - Results in the first 30 days

- Within the first month of implementation, Happy Returns has seen a 65% increase in process accuracy and a 50% boost in item processing efficiency

- A 35% faster shipping time for items sent to retailers

- Significant decrease in the physical strain on workers

About Customer

Happy Returns, a UPS company, provides end-to-end returns solutions for online merchants and shoppers through a unique combination of returns software plus reverse logistics. Through its nationwide network of Return Bar locations, Happy Returns delights shoppers by enabling them to drop off returns with no packaging or printing in under 60 seconds. Returns are consolidated and shipped together, reducing costs and increasing efficiency for retailers.

Transforming Automotive Logistics: Geek+, Geely, JDL Leading the Way

The customer

Geely Auto Group, a prominent automotive manufacturer in Asia, is steadfast in its ambition to become the most competitive and esteemed regional automotive brand. Under its umbrella are Geely Auto, Lynk & Co, and Geometry brands.

In the year 2020, Geely ushered in a groundbreaking era by adopting a modular strategy, encompassing BMA, CMA superstructures, SPA, and SEA vast architecture.

By October 2020, Geely celebrated a remarkable achievement, surpassing 10 million vehicles in cumulative global sales, a historic feat for an Asian automotive brand.

The Challenge:

- Wide Business Coverage: RDC warehouse manages storage for 400+ suppliers and over 7,000 parts, while also handling in-factory logistics.

- Storage Space Challenges: Faced with space constraints in warehouse storage.

- High Efficiency and Accuracy Demands

- High standards for picking and outbound operations.

Our Solution:

Optimized Upper-Level Storage: This innovative solution effectively utilizes upper-level storage (2-5) within the vertical warehouse. It seamlessly combines the X1200 omnidirectional robot with intelligent high-speed vertical elevators, resulting in automated bulk material storage and retrieval.

Efficient Picking at Ground Level: The P800 picking robots operate efficiently at the ground level of the vertical warehouse. They transport pallets and boxed materials to the workstation, significantly streamlining the picking process.

Geek+ Impact:

- 8000 Square Meters Saved: By maximizing upper-level storage for enhanced efficiency.

- 60% Efficiency Enhancement: Operations experience a remarkable boost in productivity.

- 99% Inventory Accuracy: Precise inventory management ensures smooth operations.

- 100% FIFO Execution: Adherence to the first-in, first-out principle is guaranteed.

Video

Geek+ and Paack Partner to Set European Benchmark for Ultra-Large Scale Sorting

The customer

Paack is a technology-enabled delivery solution provider that currently delivers millions of orders per month to approximately 150 international customers such as Amazon, Apple, Inditex, AliExpress, Nike and Nespresso.

The challenge

- Loose coupling of multiple links, need to achieve integrated management

- Full process automation with timeliness, cost and efficiency

Our solution

S series, P series

Customer value

- For the first time, "last-mile picking" and "overstock picking" are carried out simultaneously

- 1000+ shipments per hour

- 99.99% order fulfillment accuracy rate

Italian 3PL Leader Life365 Enhances Multinational Cloud Deployment with High Speed and Intelligence

The customer

LIFE365 Italy S.P.A. provides customers with cutting-edge high-tech products and builds a bridge of commerce between Asia and Europe through import and export contracts with important manufacturers in China, Japan, Korea, Singapore and other countries..

The challenge

- Long walking distance for employees, efficiency to be improved

- New employees are not familiar with the site, high training costs

- Frequent order changes, operation flexibility to be improved

Our solution

Goods-to-person

M200C

Customer value

- Significant reduction in ineffective employee movement

- Increased picking efficiency

- Smoother field operations

- Accuracy rate increased to 99.99%

ASDA launches UKs first national sortation project

About Customer

Asda Logistics Services is a hub of activity, with 39 nationwide distribution operations including 21 food depots, three clothing centers, two ambient GM hubs, two import centers, two dot.com fulfillment centers, and nine ASCs. Supporting distribution across five types of store formats as well as the delivery of parcels to customers’ homes and to store for Click and Collect, Asda Logistics Services distributes an estimated 800,000 deliveries to store and 20,000,000 deliveries to customers a year.

The challenge

- More customers shopping online, followed by surges in forward and reversed volume

- Boost Asda’s toyou e-commerce service to better serve customers

- Respond to fluctuating order volumes without having to invest in additional warehouse space.

Our Solution

- 60 Geek+ S20C robots were deployed on a sorting area of 360 sqm in Asda’s cross-docking facility.

Video

Geek+ M100 robots streamline Yanfeng’s manufacturing process

The Customer

Yanfeng is a world leader in automotive interiors focused on product development, system integration, and design. Since 2010, Yanfeng has expanded its global presence and is currently operating over 230 factories worldwide with over 65,000 employees, and 6,700 employees dedicated to development and design. By providing the automotive industry with first-class products and services, Yanfeng aims to redefine the way people relax, work and play inside their vehicles.

The Challenge

- Low efficiency of moving materials to production line

- Difficulties managing inventory

- Long material transportation path

- Labor-intensive operations due to frequent manual transfer of materials

- Difficulties visualizing the manufacturing flow and high error rates

Our Solution

- Geek+ provides Yanfeng with moving robots M100 for transferring raw materials to production lines

- Connecting Geek+ Moving System (GMS) to WMS and MES, enabling real-time visibility of the manufacturing process

The Geek+ impact

- Reduced labor costs

- 99% Material handling accuracy

- Real-time monitoring of manufacturing process

Video

Konica Minolta streamlines manufacturing process with both picking and moving solutions

The customer

Konica Minolta is a Japanese multinational technology company headquartered in Tokyo, with offices in 49 countries worldwide. The company manufactures business and industrial imaging products, including copiers, laser printers, multi-functional peripherals (MFPs) and digital print systems for the production printing market.

The challenge

- Konica was looking for an AMR solution to achieve higher accuracy of materials handling in its warehouse and replace its magnetic stripe AGVs which offer little flexibility, are subject to low operating efficiency, and lead to high maintenance costs.

- Production line consists of more than 30,000 different materials, it is costly to manage the inventory and accuracy.

- High frequency of material delivery, low efficiency of manual material delivery, poor timeliness, and high labor-intensity.

Our solution

- 10 P800 robots in the warehouse and make use of Geek+ iWMS , for precise management of materials

- 3 M100 robots featuring SLAM navigation at the production line to deliver the materials from warehouse to production line

- Geek+ Moving System (GMS) receives task from iWMS and deliver the materials to production line automatically.

The Geek+ impact

- Improved inventory accuracy

- Stock-taking frequency reduced by 92%

- Material delivery efficiency increased by 31~42%

- Storage area saved by more than 32%

- Reduced labor intensity

Video

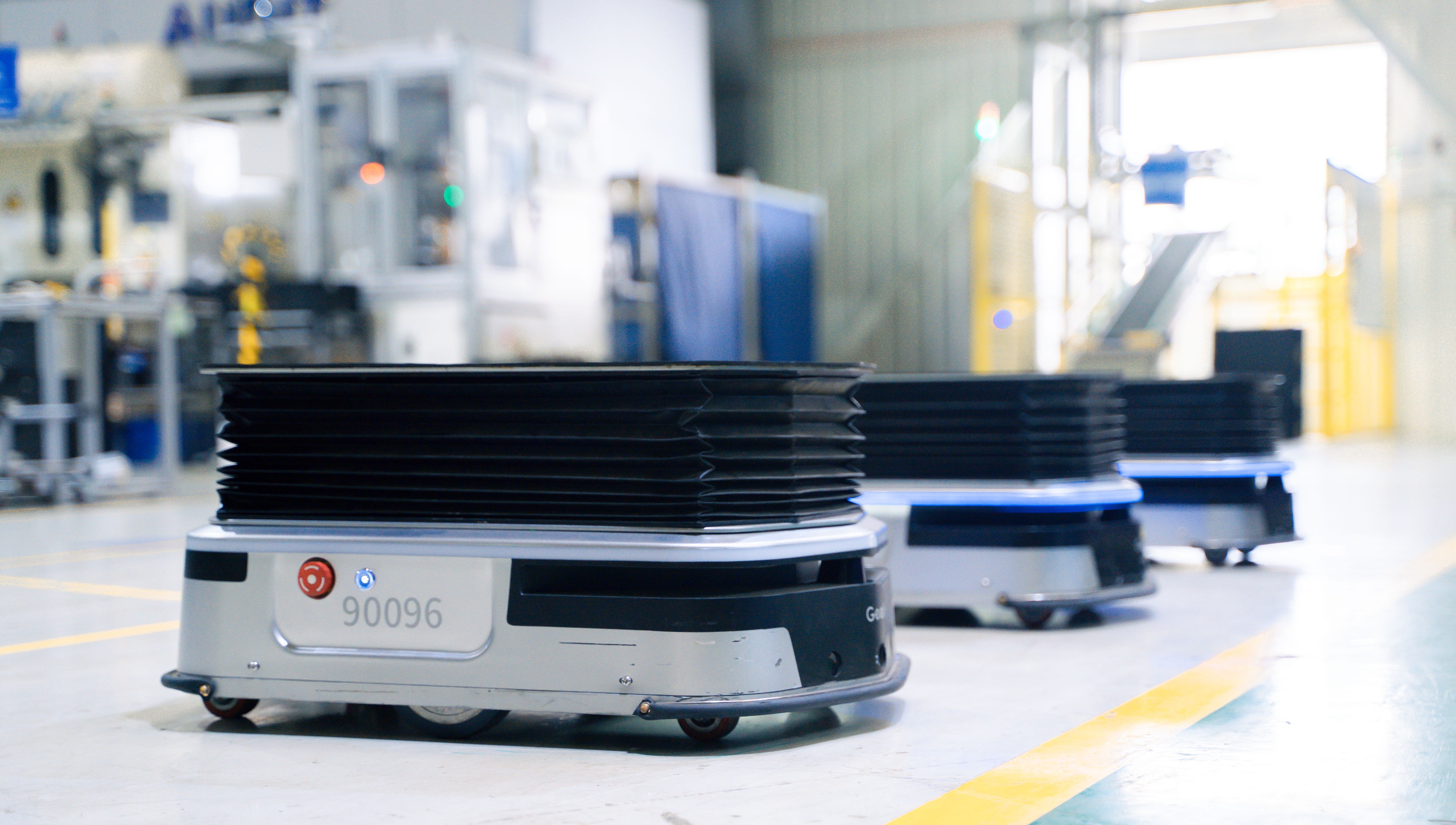

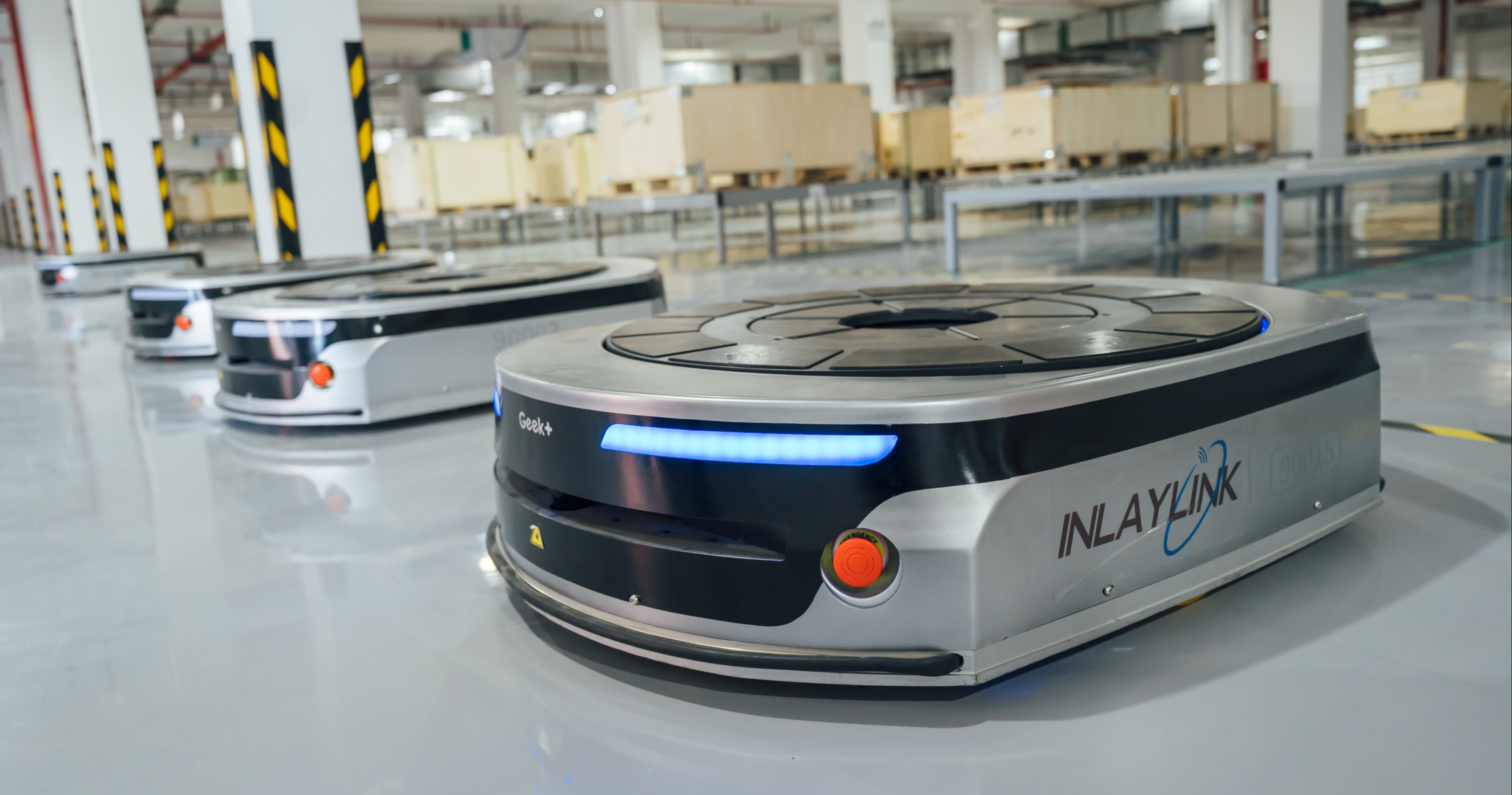

INLAYLINK factory realizes a smart upgrade with moving robots

The Customer

INLAYLINK is one of the world-renowned manufacturers of RFID tag antennas, specializing in the design, research and development, production, and sales of RFID tag antennas. It is also one of the few high-tech companies that can provide RFID data collection solutions and has won many world-known rewards.

The Challenge

- On-site materials are moved across floors and multiple areas frequently, and manual handling cannot guarantee the timeliness

- Manual handling is labor-intensive

- The value of a single material on-site is high. Checking, verification, signing, and handover are required for the delivery, online, offline, and warehousing links.

- The efficiency is low and the management cost is high.

- An information system is required to connect the warehouse and the production line to achieve physical and automatic docking of accounts.

Our Solution

- The site is equipped with 12 M1000 robots that transfers the materials out of the warehouse and sends them to the production lines.

- The robots are connected with vertical warehouse stackers, elevators, access control, and other systems to realize automatic, accurate, and timely distribution of materials across floors and sectors.

- The Geek+ Moving System (GMS) is connected to WMS and MES, enabling real-time visibility of the manufacturing process.

The Geek+ impact

- The integration information allowed a reduction in material management costs by 60%

- Material handling efficiency increased by 30%

- Reduced labor-insensitive operations

Video

Geek+ implements first large-scale AMR sorting system for Banggood’s e-commerce business

The customer

Banggood is a global e-commerce player focused on B2C cross-border export. With 37 international warehouses and deliveries bound for over 200 countries, Banggood is committed to bringing high-quality goods, efficient supply chain and top-class customer service to the world.

The challenge

Due to the accelerated shift towards e-commerce, Banggood faced challenges of rapid growth in online sales, unpredictable demand, labor shortages, and higher requirements for safer operations. With labor-intense processes often subject to inaccurate sorting, the company turned to Geek+ to automate its warehouse and realize and upgrade in its sorting operations.

Our solution

- To meet customer demand, Banggood turned to Geek+ Fleetsort solution, using a combination of S20T and P500 robots and realize more efficient and accurate operations through automated parcel sorting.

The Geek+ impact

- Reduced labor costs

- Reduced investment in fixed facilities

- Significant improvements in sorting efficiency

- 99% sorting accuracy

.png)