Featured Case Studies

Case Studies

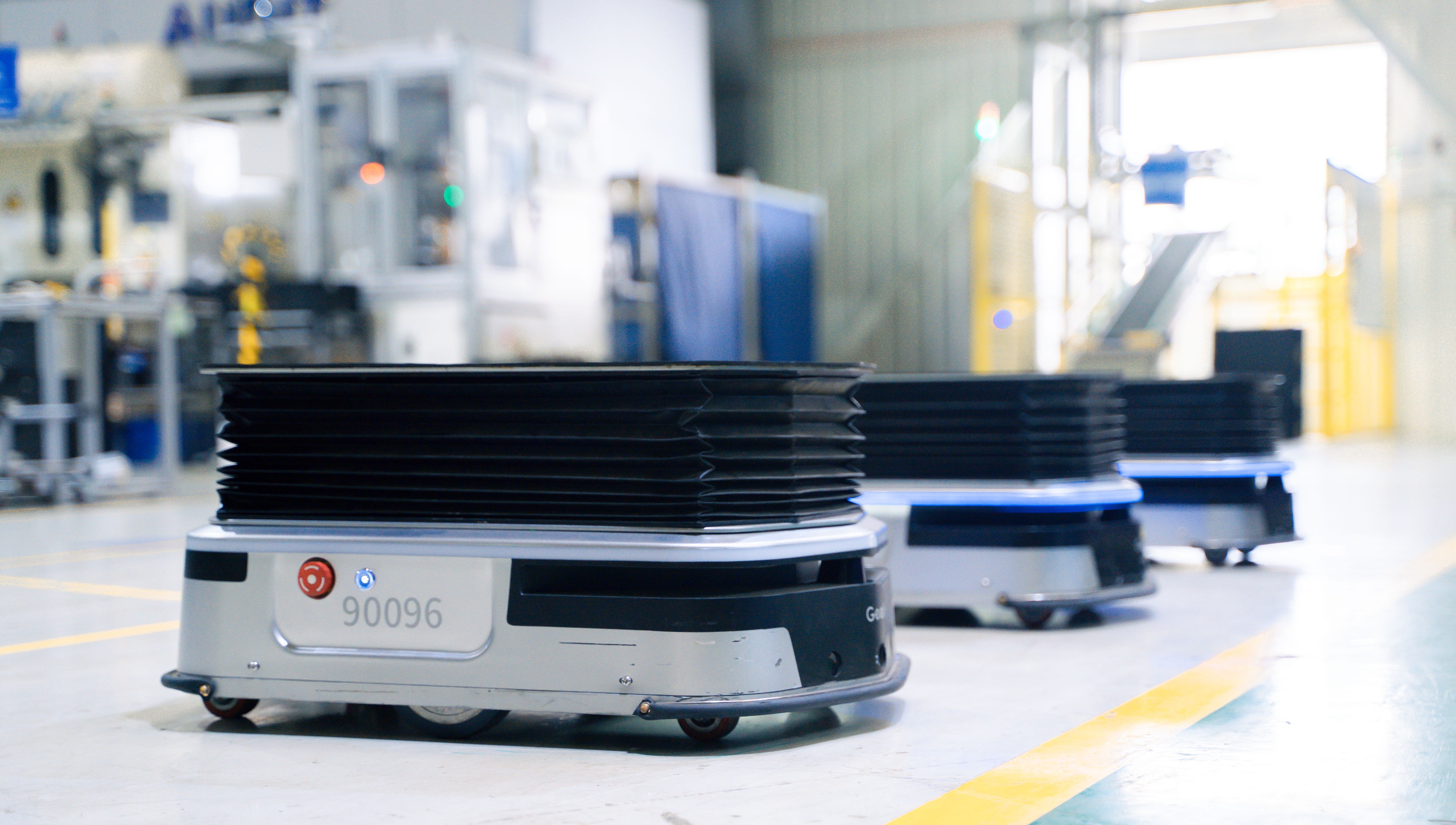

Geek+ M100 robots streamline Yanfeng’s manufacturing process

The Customer

Yanfeng is a world leader in automotive interiors focused on product development, system integration, and design. Since 2010, Yanfeng has expanded its global presence and is currently operating over 230 factories worldwide with over 65,000 employees, and 6,700 employees dedicated to development and design. By providing the automotive industry with first-class products and services, Yanfeng aims to redefine the way people relax, work and play inside their vehicles.

The Challenge

- Low efficiency of moving materials to production line

- Difficulties managing inventory

- Long material transportation path

- Labor-intensive operations due to frequent manual transfer of materials

- Difficulties visualizing the manufacturing flow and high error rates

Our Solution

- Geek+ provides Yanfeng with moving robots M100 for transferring raw materials to production lines

- Connecting Geek+ Moving System (GMS) to WMS and MES, enabling real-time visibility of the manufacturing process

The Geek+ impact

- Reduced labor costs

- 99% Material handling accuracy

- Real-time monitoring of manufacturing process

Video

Konica Minolta streamlines manufacturing process with both picking and moving solutions

The customer

Konica Minolta is a Japanese multinational technology company headquartered in Tokyo, with offices in 49 countries worldwide. The company manufactures business and industrial imaging products, including copiers, laser printers, multi-functional peripherals (MFPs) and digital print systems for the production printing market.

The challenge

- Konica was looking for an AMR solution to achieve higher accuracy of materials handling in its warehouse and replace its magnetic stripe AGVs which offer little flexibility, are subject to low operating efficiency, and lead to high maintenance costs.

- Production line consists of more than 30,000 different materials, it is costly to manage the inventory and accuracy.

- High frequency of material delivery, low efficiency of manual material delivery, poor timeliness, and high labor-intensity.

Our solution

- 10 P800 robots in the warehouse and make use of Geek+ iWMS , for precise management of materials

- 3 M100 robots featuring SLAM navigation at the production line to deliver the materials from warehouse to production line

- Geek+ Moving System (GMS) receives task from iWMS and deliver the materials to production line automatically.

The Geek+ impact

- Improved inventory accuracy

- Stock-taking frequency reduced by 92%

- Material delivery efficiency increased by 31~42%

- Storage area saved by more than 32%

- Reduced labor intensity

Video