Featured Case Studies

Case Studies

Geek+ Opens Innovation Center to Revolutionize Warehouse Automation in North America

![]()

The Customer

Outdoor Network, a major U.S. distributor of vehicles and OEM parts, faced critical operational challenges, including consolidating multi-line orders across two facilities, labor shortages, and the need to enhance efficiency to meet peak-season demands. Partnering with Geek+ and KPI Solutions, Outdoor Network deployed innovative mobile robotic solutions at their East Coast Distribution Center in Albany, Georgia.

The Challenge

Outdoor Network encountered multiple hurdles in its warehouse operations:

- The need to consolidate multi-line orders from two separate facilities.

- Ongoing labor shortages due to heightened demand for their products.

- A pressing requirement to enhance operational efficiency to cope with peak demands.

These challenges hindered Outdoor Network's ability to maintain high service levels and operational agility, demanding a scalable and efficient solution.

Our Solution

Geek+ and KPI Solutions collaborated to design and implement an advanced automation strategy tailored to Outdoor Network’s needs:

- Integration of Mobile Robotic Solutions: Mobile robots were deployed to handle oversized items, efficiently managing putaway to static shelving and pallet racks.

- Streamlined Picking Operations: Robots transported oversized picks in carts to a dedicated consolidation area for outbound shipping.

- Optimized Single Facility Approach: By merging storage and picking processes into one consolidated facility, operations were simplified and streamlined.

This solution leveraged smart automation to boost storage capacity and efficiency while addressing labor challenges through reduced dependency on manual tasks.

The Geekplus impact

The collaboration between Ariat, Geek+, and Körber yielded impressive results that transformed Ariat’s supply chain operations:

- Improved Efficiency: Warehouse picking efficiency and accuracy experienced significant enhancements, directly impacting speed and reducing errors.

- Associate Productivity Advance: Productivity doubled, with a 100% increase noted following the implementation.

- Reduced Walking Strain on Associates: Associate walking decreased by 82%, minimizing workplace fatigue and improving employee satisfaction.

- Compliance with Demand Surges: The scalability of Geek+’s robots ensured Ariat could effectively meet demand spikes without operational bottlenecks.

Video

Geek+ and George: Optimizing Returns and Fulfillment Processes

The Customer

Founded as part of the larger Asda family, George is a prominent UK-based clothing brand that caters to diverse consumer needs. With its growing online presence and high demand for affordable, high-quality apparel, George faces the continuous challenge of managing extensive inventory and returns, particularly during busy shopping periods such as the holiday season.

The Challenge

George's rapid expansion, coupled with high return volumes and increasing customer expectations, presented several operational challenges:

- Returns Burden: Managing returns during peak seasons strained warehouse operations and delayed getting products back into inventory.

- Fulfillment Efficiency: The need for faster order picking and processing across the warehouse.

- Storage Optimization: Limited storage capabilities made it difficult to manage fluctuating SKU volumes efficiently.

- Labor Demands: Dependence on manual processes increased costs and led to inefficiencies.

Our Solution

To address these challenges, George collaborated with Geek+ and AMH Material Handling to implement an advanced customized goods-to-person returns system, featuring:

- 4-Sided Rack Design: Geek+ deployed its P800 returns solution, which allows workers to perform both picking and put-away tasks simultaneously from any open rack slot.

- Intelligent Automation: The solution automated processes for returning items to inventory, significantly reducing handling time.

- Optimized Storage Locations: By using fewer racks effectively, the solution increased storage location availability while maintaining capacity for 700 SKUs and 7,200 units daily.

- User-Friendly Operations: Designed with worker ergonomics in mind, the system improved ease of use and operational flow for staff.

The Geekplus impact

The implementation delivered measurable results for George, including the following benefits:

- Faster Returns Processing: Returned items were stocked back in inventory on the same day, improving product availability during high-demand periods.

- Higher Fulfillment Rates: Automated picking and put-away capabilities enhanced speed and ensured operational efficiency during peak seasons.

- Optimized Warehouse Utilization: The streamlined storage system allowed George to maximize space and minimize disruptions caused by high stock volumes.

- Enhanced Worker Experience: The ergonomic and intuitive system reduced manual workload, allowing staff to focus on higher-value tasks.

- Improved Customer Satisfaction: Faster order turnarounds ensured timely deliveries, elevating the overall shopping experience.

“I’m delighted to see this project go live, supporting the growth of our George.com business. The collaboration between internal teams, AMH, and Geek+ has resulted in a high-quality solution that enhances the colleague experience and significantly improves operational effectiveness.”

Chris Hall, Vice President, Asda Logistics Services

X5 Retail Group and Geek+: Revolutionizing Retail Logistics with Smart Sorting Systems

The Customer

- X5 Retail Group stands as one of the largest and most innovative retail companies in Russia, with a prominent presence across the country's expansive consumer market. Founded in 2006, the group has grown rapidly, earning a reputation for its diverse retail formats, cutting-edge technology adoption, and customer-first strategies that cater to millions daily.

Video

Geek+ and Hunkemöller Redefine Warehouse Efficiency with Robotics on a Mezzanine

The Customer

Hunkemöller is a global leader in the lingerie and retail industry, with an extensive presence across Europe. Known for its stylish products and customer-centric approach, the brand has consistently embraced innovation to improve operations. The Almere warehouse in the Netherlands serves as a critical hub for fulfilling orders efficiently while maintaining the high service standards that Hunkemöller’s customers expect.

The Challenge

To meet the growing demands of e-commerce while managing space limitations, Hunkemöller faced several challenges, including:

- Space Constraints: A need to utilize the full vertical height of their warehouse efficiently.

- Demanding Order Fulfillment: The pressure to streamline and scale operations due to increasing order volumes.

- Maximizing Automation Potential: A requirement for a solution that integrates technology seamlessly while adhering to sustainability goals.

Our Solution

Hunkemöller partnered with Geek+ to implement a forward-thinking warehouse automation system that addressed these challenges head-on:

- Fleet of 160 Geek+ Robots: Equipped with advanced features, these AMRs optimized movement and storage on the mezzanine floor.

- 8.6-Meter-High Mezzanine: The innovative installation leveraged vertical space, proving that AMRs can operate efficiently at impressive heights.

- Order Picking Optimization: Enhanced speed and precision in item retrieval ensured faster and more accurate processing.

- Smart Storage Utilization: The solution prioritized smarter storage organization, reducing wasted space and increasing productivity.

- Sustainable Infrastructure: Built on a sustainable mezzanine floor, provided by Anera B.V., aligning with Hunkemöller’s environmental responsibility goals.

The Geekplus impact

By integrating Geek+’s robotics technology, Hunkemöller realized significant benefits, including:

- Higher Efficiency: Streamlined order picking processes boosted operational speed and accuracy.

- Space Maximization: The automated solution unlocked previously underutilized vertical warehouse space.

- Scalability: The modular system enables adjustments to accommodate seasonal demand increases.

- Customer-Centric Outcomes: Enhanced fulfillment operations ensured better customer satisfaction and loyalty.

- Sustainability: The mezzanine installation underscored Hunkemöller’s commitment to eco-friendly practices.

Video

Geek+ and Hessing Revolutionize Food Logistics with Robotics

The Customer

Hessing Supervers has been a trusted name in fresh produce processing for over 50 years. Specializing in ready-to-cook vegetables, processed fruits, and meal salads, Hessing supplies retail chains, fast-food outlets, and inflight caterers across the Netherlands, Belgium, Germany, and Denmark. Handling millions of packages weekly, the company sought to modernize operations to keep pace with growing demand and maintain its commitment to freshness and quality.

The Challenge

Operating in the highly competitive fresh food market, Hessing faced several operational challenges:

- Complex Workflow Management: Their Greenport Venlo site required seamless coordination across washing, mixing, and packaging zones.

- Time Sensitivity: With fresh produce having limited shelf life, delays in processing and distribution could lead to increased food waste and cost inefficiencies.

- Scalability Needs: Rising demand for pre-packaged fruits and vegetables necessitated a logistics solution capable of efficient scaling.

- Employee Safety and Productivity: Managing a three-story facility posed increased risks and physical demands on employees.

Our Solution

Hessing turned to Geek+ to implement a state-of-the-art logistics system designed to meet these challenges head-on. Key features of the solution included:

- 112 Geek+ M200 Robots: These autonomous mobile robots connected distinct processing areas and ensured seamless movement of goods across floors.

- AI-Driven Fleet Management: Utilizing advanced algorithms, the central AI monitored hundreds of robots simultaneously to optimize routes, reduce traffic congestion, and ensure peak performance.

- 3D Obstacle Detection: Robots were equipped with sensors to identify and safely bypass obstacles, maintaining the highest safety standards for employees and products.

- Three-Story Operation Integration: The AMRs operated on multiple levels, ensuring end-to-end coverage of the distribution process while optimizing vertical space utilization.

- Streamlined Food Processing Workflow: The system enabled faster transitions between washing, mixing, and packaging stations, minimizing hold-ups and preserving the freshness of produce.

The Geekplus impact

The new system delivered outstanding results for Hessing, including:

- Efficiency Gains: Robots transformed workflow efficiency, enabling faster processing times and timely produce delivery.

- Reduced Food Waste: The intelligence-driven logistics minimized delays, ensuring higher percentages of products reached consumers in peak condition.

- Fresher Produce: Accelerated movements through the supply chain enabled retailers to enjoy longer product shelf lives.

- Enhanced Safety and Productivity: Employees reported improved working conditions due to reduced physical strain and optimized facility operations.

- Scaled Operations: The innovative system positioned Hessing to expand its operations in response to rising demand without adding logistical bottlenecks.

“By automating our distribution center with Geek+’s moving solutions, we’ve made our ‘factory of the future’ vision a reality. We now bring healthier food to consumers faster and with less waste—an achievement we are truly proud of.”

Hans Hessing, Director Center of Excellence, Hessing Supervers

Video

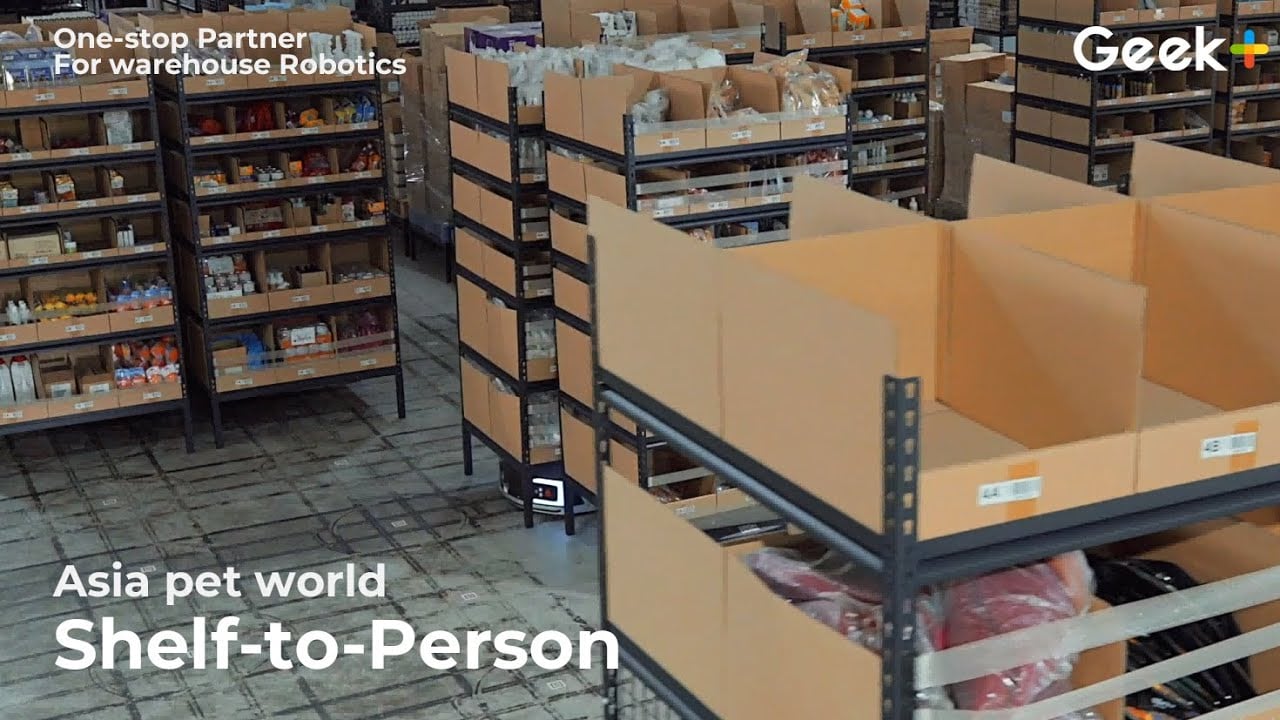

Asia PetWorld and Geek+ Collaborate to Revolutionize Warehousing in the Pet Supply Industry

The Customer

- Asia PetWorld, a global leader in pet supply distribution, handles 8,000 unique SKUs daily.

- Supplies a wide range of pet products, including large pet beds, cat litter, and bulk dog food.

- Operates in a labor-intensive and complex warehousing landscape with high product diversity.

The Challenge

- High SKU volume: Managing a vast assortment of 8,000 SKUs demanded significant labor and resources.

- Rising labor costs: Increasing operational expenses due to dependency on manual labor.

- Handling heavy, bulky items: Products such as large pet beds and bulk pet food added physical strain on workers.

- Labor shortages: Difficulties in maintaining efficient operations due to workforce shortages.

Our Solution

- Robots capable of efficiently handling bulky and heavy items, such as large pet beds, cat litter, and dog food.

- Improved inventory management through intelligent automation, enabling operational flexibility.

- Enhanced employee ergonomics by reducing the physical strain of manual tasks, fostering a safer and healthier work environment.

The Geekplus impact

- Efficient operations: A 99.5% picking accuracy leading to more reliable order fulfillment.

- Employee well-being: Reduced physical strain and created a safer, more comfortable work environment for workers.

- Rapid transformation: Warehouse operations were revolutionized within just two months.

- Scalable solution: The robotics system ensured flexibility for future growth and changes.

- Customer satisfaction: Enhanced inventory management improved overall customer service experience.

“In Singapore, the labor availability is always a challenge for warehouse owners. The situation is even worse for the pet industry where workers often need to manage heavy, awkward items. After adopting the Geek+ robots, we are better able to handle our stocks and can offer a more comfortable workplace to our employees.”

Sebastian Wiradharma, Director, Asia PetWorld

Video

Geek+ Implements Japan's Largest Shelf-to-Person PopPick System for ASKUL

The Customer

ASKUL is a leading Japanese company offering a wide range of products and services to businesses. Established in 1993, ASKUL has cemented its reputation as one of Japan’s primary suppliers of office supplies and equipment. With a dedication to operational excellence, ASKUL has consistently embraced innovative technologies to improve its logistics network and provide exceptional customer experiences.

The Challenge

ASKUL faced significant operational hurdles as its product portfolio and customer base expanded over the years. The primary challenges included:

- Growing Inventory Needs: The company's diversified product line demanded storage solutions capable of handling higher volumes more efficiently.

- Limited Storage Space: ASKUL needed to maximize storage density to utilize its warehouse space effectively.

- Operational Scalability: Addressing increased demand required solutions that could handle higher order volumes without compromising speed or accuracy.

To meet its growth objectives while maintaining superior service standards, ASKUL turned to Geek+ for an innovative automation solution.

Our Solution

- Fleet of AMRs: Highly autonomous robots enhanced goods retrieval and inventory workflows, reducing reliance on manual labor.

- Smart Sorting System: Advanced sorting solutions integrated seamlessly to handle high-volume orders with unmatched accuracy.

- Vertical Space Optimization: Innovative racking systems maximized floor-to-ceiling storage, accommodating increasing inventory needs.

- Interactive Data Visualization: Real-time dashboards offered full visibility into operational performance and streamlined decision-making.

The Geekplus impact

Geek+ provided ASKUL with a cutting-edge Shelf-to-Person PopPick System tailored to the unique demands of their operation. Key features of the solution included:

- High-Storage-Density Logistics: The PopPick System incorporates picking robots that transport movable shelves from storage locations to PopPick workstations. The robotic arms at these stations present totes or boxes directly to operators, ensuring seamless item retrieval.

- Streamlined Warehousing Workflows: The system enables efficient picking processes, handling up to 500 lines per hour, significantly improving workflow automation.

- Scalable Robot Deployment: With over 318 robots integrated into the ASKUL Value Center, the robots work cohesively to optimize space utilization and throughput.

- Enhanced Customer Service: By implementing a logistics system characterized by speed, precision, and scalability, ASKUL improves order accuracy and delivery performance for its customers.

This solution not only meets current demands but also sets up ASKUL for sustainable growth, with room for further innovation and scaling.

“The Geek+ PopPick System is designed for high efficiency and can significantly improve the overall productivity of warehouse operations. This implementation will showcase to the market the next generation of warehouse automation, setting a new industry benchmark.”

Hirokazu Kato, President and CEO of Geek+ Japan

Video

Geek+ Elevates PChome’s Logistics Efficiency in LinKou A7 Smart Logistics Park

The Customer

PChome is Taiwan’s premier e-commerce company, renowned as the first platform in the country to offer 24-hour fast delivery. Founded over two decades ago, PChome has consistently innovated to cater to the shopping needs of millions of customers across Taiwan. With a mission to provide timely, reliable, and sustainable services, PChome continues to lead the industry through technology-driven advancements in logistics and customer experience.

The Challenge

PChome operated in one of the most competitive e-commerce markets, facing several critical challenges:

- Meeting Next-Day Delivery Standards: The rapid growth of online shopping increased the pressure to meet its 24-hour delivery promise to millions of customers.

- Manual Inefficiencies: Pre-automation systems required workers to walk to shelves for picking orders, resulting in time-consuming processes and diminished productivity.

- Scalability Gaps: Seasonal and peak sales periods required scalable solutions to prevent bottlenecks and delays in operations.

- Sustainability Goals: PChome sought a greener logistics model to align with its “green shopping” initiative and reduce the energy footprint of warehouse operations.

To address these challenges, PChome needed an innovative logistics solution designed to improve efficiency, accuracy, and scalability while minimizing environmental impact.

Our Solution

PChome partnered with Geek+ to implement a large-scale robotics automation solution in its 45,000-square-meter multi-level LinKou A7 Smart Logistics Park. Core elements of the solution included:

- Hundreds of AMR Robots: Geek+ deployed a robust fleet of Autonomous Mobile Robots (AMRs), capable of operating around the clock. These robots transported goods from storage to workstations, streamlining operations and eliminating unnecessary manual movement.

- Pallet and Tote Automation Systems: Geek+ introduced both pallet-based and tote-based shuttle systems. These intelligent systems delivered goods directly to pickers using the “goods-to-person” method, significantly reducing walking time for staff.

- Sustainability Integration: The robotics’ ability to operate in a lights-off warehouse reduced energy consumption by eliminating the need for artificial lighting during operations, aligning with PChome’s sustainability efforts.

- Seamless Scalability: The solution was designed to accommodate growing demand, enabling PChome to handle peak sales volumes efficiently, including the capacity to process 200,000 daily orders during high-demand

The Geekplus impact

The deployment of Geek+ robotics in the LinKou A7 Smart Logistics Park yielded remarkable outcomes:

- Efficiency Tripled: Picking efficiency increased by 3X as robots minimized walking time and streamlined the picking process. This enabled faster order processing and on-time fulfillment of PChome’s 24-hour delivery promise.

- Enhanced Productivity: The warehouse’s daily order capacity doubled post-automation, ensuring seamless operations even during peak periods.

- Environmental Benefits: Thanks to automated, lights-off warehouse operations, energy usage was significantly reduced, reinforcing PChome’s commitment to green logistics principles.

- Improved Employee Workspace: Workers experienced reduced physical strain, as heavy lifting and walking were replaced by robot-assisted operations, creating a safer and more ergonomic environment.

“The deployment of Geek+ robots has revolutionized our logistics capabilities, transforming inefficiencies into strengths. With this partnership, we’re able to keep pace with the evolving demands of e-commerce while adhering to our sustainability mission.”

Ms. YuShan Zhang, CEO of PChome

Video

Geek+ and Comix Introduce the First Robot Fleet Solution in Enterprise Services

The Customer

Comix Group, founded in 1991, specializes in government and enterprise procurement services. With a global presence spanning over 120 countries and regions, Comix has excelled in delivering comprehensive solutions for enterprises.

The Challenge

- Limited storage capacity constrained by traditional warehouse setups.

- Rising operational demands, including the need to handle diverse product sizes and types.

- Manual inventory processes leading to inefficiencies and increased costs.

- High requirements for accuracy, speed, and safety in order fulfillment operations.

Our Solution

Geek+ implemented an intelligent solution tailored to address Comix's needs. Key features included:

- RoboShuttle® + P40 Robots — A highly flexible goods-to-person system optimized for dense storage and picking.

- Four-Way Shuttle Vehicles — Designed for intensive storage, making full use of vertical and horizontal space.

- Smart Tally System — Intelligent algorithms that automatically adjust inventory distribution and improve outbound order efficiency.

- Operator Safety Enhancements — Robots equipped to adjust to comfortable heights for picking, reducing operator fatigue and injury risks.

The Geekplus impact

The integration of Geek+'s innovative technologies delivered exceptional value to Comix:

- 40% Increase in Space Utilization — Maximizing the available warehouse area by leveraging innovative storage solutions.

- 200% Growth in Storage Capacity — Accommodating significantly more inventory within the same footprint.

- 50% Improvement in Picking Efficiency — Streamlining operations and ensuring quicker order fulfillment.

- 50% Reduction in Labor Costs — Automation reduced reliance on manual processes.

- 99.99% Accuracy — Ensuring near-perfect order picking and inventory management.

- Sustainability and Safety — A noise-free, low-carbon system that prioritizes environmental and operational safety.

Video

Starbucks and Geek+ Transform Distribution with Smart Supply Chain Solutions

The Customer

Starbucks, a globally renowned coffeehouse chain, operates thousands of stores worldwide, offering millions of customers consistent quality and service each day. To maintain its position as an industry leader, Starbucks sought to optimize its supply chain to address increasing logistics demands and ensure operational excellence.

The Challenge

- Complex Store Distribution: Meeting the growing logistical needs across a vast network of locations.

- Operational Inefficiencies: Manual processes leading to bottlenecks in sorting, picking, and distribution.

- High Logistics Volume: Challenges in managing the scalability of operations during peak seasons.

- Data Integration: Necessity of a unified system to manage storage, picking, container handling, and distribution efficiently.

Our Solution

TTX, in collaboration with Geek+, deployed a cutting-edge system designed to transform Starbucks’ store distribution warehouses. Key features included:

- TTX WES and Geek+ PopPick Integration: A powerful combination of WES task scheduling and goods-to-person robotics for maximum automation.

- Advanced Robotics: Geek+ AGVs optimized picking and sorting processes, enhancing accuracy and speed.

- Intelligent Sorting: Automated systems integrated electronic labeling for seamless identification and sorting of goods.

- Container Management System: Streamlined operations ensured efficient use of containers and reduced manual oversight.

- Comprehensive Automation: Unified WMS, AGV picking, and sorting created a singular, intelligent, and cohesive supply chain.

The Geekplus impact

Starbucks realized significant measurable benefits from the integrated smart logistics system, including the following highlights:

- Improved Efficiency: Fully automated processes drastically reduced operational delays.

- Enhanced Accuracy: Robotics and electronic labeling minimized human error in picking and sorting.

- Scalability: The system handled increased logistics demands with ease, including peak volume periods.

- Optimized Task Scheduling: TTX WES ensured smooth and intelligent task workflows, boosting productivity.

- Future-Proofed Operations: The scalable, integrated solution positioned Starbucks to maintain its edge in a competitive market.

Video

Transforming Fulfillment: How RangePlus Leveraged Geek+ Automation for Growth

The Customer

Established in 2014, RangePlus is a leading pure-play online retailer based in Croydon, UK. Utilizing a 13,500-square-foot fulfillment center, the company manages a diverse portfolio of approximately 4,000 SKUs, including toiletries, cosmetics, confectionery, and grocery products. RangePlus is known for its high-quality service and commitment to operational excellence, ensuring customers receive a seamless shopping experience.

The Challenge

With an expanding product catalog and customer base, RangePlus encountered several key operational challenges:

- Inefficient Order Fulfillment: Manual order-picking processes could not keep up with increasing customer demand, leading to slower fulfillment times.

- Space Constraints: The warehouse struggled to accommodate more SKUs, limiting RangePlus’s ability to diversify its offerings.

- Growing Costs: Rising labor and operational expenses were eating into profitability, requiring a more efficient approach.

- Scalability: RangePlus needed a flexible, technology-driven solution to sustain growth without compromising service quality.

Our Solution

Geek+ implemented a robust, automated goods-to-person solution optimized to meet RangePlus’s operational needs. Key components of the solution included:

- Continuous Fulfillment Capabilities: The system operates 24/7, ensuring round-the-clock productivity and faster order processing.

- Advanced Robotics Technology: A network of automated goods-to-person systems streamlined picking and replenishment tasks with exceptional precision.

- Warehouse Optimization: By optimizing space within the 13,500-square-foot facility, RangePlus was able to increase storage capacity by 50%, enabling them to stock 243,000 SKUs.

- Efficiency Improvements: The innovative system reduced order-picking times, significantly boosting productivity and operational scalability.

The Geekplus impact

The deployment of the Geek+ solution delivered significant outcomes for RangePlus:

- 300% Increase in Picking Rates: The automation tripled the pick speed, streamlining order processing and reducing lead times.

- 25% Reduction in Operating Costs: Automation minimized labor-intensive tasks, cutting operating expenses substantially.

- Warehouse Capacity Maximization: RangePlus successfully increased storage by 50%, accommodating more SKUs without expanding the facility.

- Rapid ROI: The company achieved a full return on investment in less than two years.

“Our partnership with Geek+ has completely transformed our fulfillment operations. The efficiency gains have been extraordinary, allowing us to grow our product range and maintain cost control. Achieving our ROI in under two years underscores the effectiveness of Geek+ solutions.”

RangePlus Management

Video

Newegg Enhances Warehouse Efficiency with Geekplus Robotics

About Customer

Newegg Commerce, Inc., founded in 2001 and based in the City of Industry, Calif., near Los Angeles, is a leading global online retailer for PC hardware, consumer electronics, gaming peripherals, home appliances, automotive and lifestyle technology. Newegg also serves businesses’ e-commerce needs with marketing, supply chain, and technical solutions in a single platform.

The Challenge

Newegg was looking to address two main challenges with its order fulfillment operations:

-

ways in which it could improve safety for its associates by reducing physically demanding tasks and eliminating the need to walk long distances to fulfil orders.

-

how the company could enhance its fulfillment operations with faster and more accurate order processing.

Our Solution

The Geekplus Shelf-to-Person picking solution augmented order fulfillment operations for Newegg's 240,000 sq. ft. warehouse in Onatrio, California. The solution equipped Newegg with the ability to seamlessly handle more than 20,000 SKUs, improved associate safety and well-being, and strengthened overall picking productivity and accuracy. Newegg has also realized cost savings and improved storage utilization.

The Geekplus impact

- Increased picking efficiency

- Reduced walking distances for associates

- Faster and easier training process for associates

- Implementation in 6 weeks

Video

.png?width=200&height=200&name=images%20(1).png)

-1.jpg?width=200&height=66&name=Hessing%20Corporate%20SV%20logo%2070cm(1)-1.jpg)