Featured Case Studies

Case Studies

Geekplus

Recent Posts

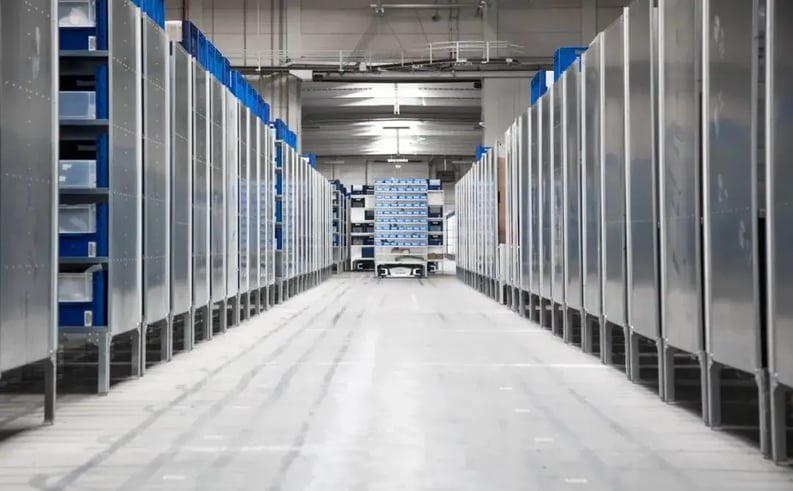

Geekplus, BlueSkye and Oneiro Transform SHIP8's Warehouse Through Integrated Automation

The Challenge

Handling bulky and large items that take up significant warehouse space, SHIP8 faced the need to optimize their 1.1 million sq. ft. facility. This challenge intensified during the pandemic, as labor shortages coincided with a surge in their e-commerce business. To address these issues, SHIP8 sought a fully automated solution to enhance storage capacity and operational efficiency.

Our Solution

With BlueSkye Automation and Oneiro Technologies's support, Geekplus automated SHIP8's fulfillment center with integrated technologies consisting of robotic arms, sorting systems, Shelf-to-Person systems, and Pallet-to-Person systems. These solutions are designed for maximum efficiency, capable of running 24 hours a day during peak seasons when demand is high.

The Geekplus impact

-

Completely automated case receiving, pallet building and put-away functions

-

Increased order case picking efficiency from 40 per hour per person to 450-500 per automated robotic workstation

-

Improved utilization of existing warehouse square footage of 27,000 pallet

-

Shortened extensive training time and reduced labor reliance by 81%

About Ship8

SHIP8 INC. is a world class technology driven 3PL leader offering comprehensive Logistics and Transportation services at Budget-Friendly Rates. Leveraging our CTPAT and FDA certified distribution centers in close proximity to the (Port of Savannah, Port of Brunswick, Port of Jacksonville, Port of Charleston and Port of Oakland) our experienced team uses the latest breakthroughs in Automation, Robotics and Warehouse Management Systems to meet all of your Drayage, Ecommerce and Wholesale Supply Chain requirements.

About BlueSkye

As the warehousing industry evolves and grows in complexity, distribution and fulfillment centers face increasingly challenging demands for higher throughput with reduced labor. This level of efficiency can only be achieved through automation. BlueSkye Automation is a leading provider of turnkey automated material handling and intralogistics solutions that increase productivity, safety and warehouse efficiencies. Our dynamic team has the experience and expertise to ensure your project is successful from initial consultation to post implementation support meeting the needs of our customers and utilizing leading-edge technologies.

About Oneiro

Oneiro Technologies was founded with a commitment to make innovative material handling solutions accessible to all. We bring robotics, augmented/extended reality, fulfillment software, and AI to operations of all sizes by being lean and having strategic partnerships. We are nimble and able to adapt to your needs.

Officeworks Transforms Supply Chain with Geek+'s Solar-powered Robot Fleet.

About Customer

Officeworks is a chain of Australian office supply stores. Officeworks offers customers a wide range of office supplies, technology, furniture and art supplies. It operates 168 stores across Australia, a website that is home to more than 40,000 products, a national call centre, and a business team that helps micro, small and medium-sized businesses start, run and grow.

The Challenge

Officeworks needed to enhance its supply chain efficiency and manage a vast product range across multiple distribution functions, including online orders, cross-docking, and international distribution.

Our Solution

Officeworks launch an 15,000 sqm advanced customer fulfilment center (CFC) in Perth, Western Australia, equipped with 90 Geek+ autonomous solar-powered Geek+ mobile robots.

The Geekplus impact

-

Increased bulk storage capacity

-

Improved stock fulfillment

-

Maximized delivery operations

Newegg Enhances Warehouse Efficiency with Geekplus Robotics

About Customer

Newegg Commerce, Inc., founded in 2001 and based in the City of Industry, Calif., near Los Angeles, is a leading global online retailer for PC hardware, consumer electronics, gaming peripherals, home appliances, automotive and lifestyle technology. Newegg also serves businesses’ e-commerce needs with marketing, supply chain, and technical solutions in a single platform.

The Challenge

Newegg was looking to address two main challenges with its order fulfillment operations:

-

ways in which it could improve safety for its associates by reducing physically demanding tasks and eliminating the need to walk long distances to fulfil orders.

-

how the company could enhance its fulfillment operations with faster and more accurate order processing.

Our Solution

The Geekplus Shelf-to-Person picking solution augmented order fulfillment operations for Newegg's 240,000 sq. ft. warehouse in Onatrio, California. The solution equipped Newegg with the ability to seamlessly handle more than 20,000 SKUs, improved associate safety and well-being, and strengthened overall picking productivity and accuracy. Newegg has also realized cost savings and improved storage utilization.

The Geekplus impact

- Increased picking efficiency

- Reduced walking distances for associates

- Faster and easier training process for associates

- Implementation in 6 weeks

Video

Geek+ Empowers UPS with Flexible Solutions

About Customer

UPS Supply Chain Solutions® offers a comprehensive portfolio of services to enhance customers' business performance, including logistics, distribution, and transportation.

The Challenge

To meet the growing demand of a new customer, UPS Supply Chain Solutions® needed to reconfigure its warehouse layout to make room for new products and to scale up its operations with more Shelf-to-Person mobile robotic automation.

Our Solution

The relocation of 1,018 racks to a different warehouse area was completed in less than four hours. This ensured minimal disruptions to UPS's existing operations, and also provided the necessary space to begin deploying a new Geek+ Shelf-to-Person PopPick solution. Together, the existing standard system and the new PopPick system serve multiple UPS clients with different product categories in the same solution.

The Geek+ impact

- Scaled easily to meet the demands of UPS's growing business

- No infrastructure changes - flexibility to adjust automation layout and location within the same facility

- Minimal disruption to existing operations

- Ability to serve multiple clients with different product categories in one solution

Video

Geek+ Equips UPS with Faster E-Commerce Order Fulfillment

About Customer

UPS Supply Chain Solutions® offers a comprehensive portfolio of services to enhance customers' business performance, including logistics, distribution, and transportation.

UPS Supply Chain Solutions® offers a comprehensive portfolio of services to enhance customers' business performance, including logistics, distribution, and transportation.

Allbirds is a global lifestyle brand that innovates with naturally derived materials to make footwear and apparel products in a better way, while tredding lighter on the planet.

brand that innovates with naturally derived materials to make footwear and apparel products in a better way, while tredding lighter on the planet.

The Challenge

With a wide range of order profiles from its footwear and apparel customer, Allbirds, UPS Supply Chain Solutions® needed a scalable yet standardized automation solution that could be seamlessly expanded across multiple distribution centers.

Our Solution

After initially starting with 27 P-800 goods-to-person picking robots, UPS Supply Chain Solutions® scaled its automation to 184 robots across two warehouses covering the West and East Coast of the United States.

The Geek+ impact

- 97% increase in peak unit throughput year over year

- 400% increase in picked units per hour year over year

- Experienced back-to-back record days during Peak

- Multi-lingual system allows for greater employee inclusion

- Accelerated training time from 1 week to approximately 2 hours

- Flexibility to share labor between multiple operations

Transforming Automotive Logistics: Geek+, Geely, JDL Leading the Way

The customer

Geely Auto Group, a prominent automotive manufacturer in Asia, is steadfast in its ambition to become the most competitive and esteemed regional automotive brand. Under its umbrella are Geely Auto, Lynk & Co, and Geometry brands.

In the year 2020, Geely ushered in a groundbreaking era by adopting a modular strategy, encompassing BMA, CMA superstructures, SPA, and SEA vast architecture.

By October 2020, Geely celebrated a remarkable achievement, surpassing 10 million vehicles in cumulative global sales, a historic feat for an Asian automotive brand.

The Challenge:

- Wide Business Coverage: RDC warehouse manages storage for 400+ suppliers and over 7,000 parts, while also handling in-factory logistics.

- Storage Space Challenges: Faced with space constraints in warehouse storage.

- High Efficiency and Accuracy Demands

- High standards for picking and outbound operations.

Our Solution:

Optimized Upper-Level Storage: This innovative solution effectively utilizes upper-level storage (2-5) within the vertical warehouse. It seamlessly combines the X1200 omnidirectional robot with intelligent high-speed vertical elevators, resulting in automated bulk material storage and retrieval.

Efficient Picking at Ground Level: The P800 picking robots operate efficiently at the ground level of the vertical warehouse. They transport pallets and boxed materials to the workstation, significantly streamlining the picking process.

Geek+ Impact:

- 8000 Square Meters Saved: By maximizing upper-level storage for enhanced efficiency.

- 60% Efficiency Enhancement: Operations experience a remarkable boost in productivity.

- 99% Inventory Accuracy: Precise inventory management ensures smooth operations.

- 100% FIFO Execution: Adherence to the first-in, first-out principle is guaranteed.

Video

Over 200 AMRs help DB Schenker speed up the delivery of Adidas orders

The Customer

DB Schenker is the third largest brand of Deutschen Bahn AG since 2007, along with DB Bahn and DB Netze. Its business scope includes All transport and logistics services of the DB Group. One of the world's leading providers of international transportation and integrated logistics services.

The Challenge

- Guaranteed timely order processing and fast delivery

- Reduce carbon emissions

- Improve customer experience

Our Solution

- Geek+ standard shelf-to-person solution

- More than 200 AMR robots

Geek+ Impact

- The average daily processing order exceeds 120,000

- Empower customers such as Adidas to fulfill online orders at lightning speed

- Guaranteed seamless returns order processing

- Reduce carbon emissions throughout the distribution process

Video

153 AMRs in 15,000 square meters warehouse, German manufacturing leader OEG in 3 months to achieve the transformation

The Customer

OEG is a global specialist in advanced heating, ventilation and air conditioning, supplying German wholesalers and manufacturers as well as the international market with the components needed for heating, ventilation and air conditioning systems.

The Challenge

- 15,000 sq. ft. warehouse with over 80,000 kinds of parts, access efficiency needs to be improved

- High demand for shelving due to the large number of specialized products and different size SKUs

- To cope with the order flood and business expansion, high flexibility solution is needed

Our Solution

Goods-to Person, P800

Customer value

- Go live within 3 months without production downtime

- Customized shelves flexibly adapt to customer needs

- Easily cope with order floods

- Effectively manage operating costs

Leading the way in Four-way Shuttle solution for more than six months, Tica builds a digital smart production base

The customer

Founded in 1991, Tica is committed to becoming the world's leading system supplier and service provider of intelligent environment and green energy. After 31 years of innovative development, its leading products have been the first in the national market share for 12 consecutive years, and its products are widely used in projects such as Bird's Nest, Water Cube, C919 large aircraft, big rocket, Baihetan Hydropower Station, etc.

The challenge

- Traditional manual efficiency and accuracy to be improved

- Warehouse capacity needs to be improved

- Need to ensure information pull-through and product stability without stopping

Our solution

Four-way Shuttle Solution

Customer value

- Significant increase in warehouse utilization

- Improved operational efficiency

- Human-machine mixing is safe and reliable

- Full manufacturing process information pull-through

Geek+ and Paack Partner to Set European Benchmark for Ultra-Large Scale Sorting

The customer

Paack is a technology-enabled delivery solution provider that currently delivers millions of orders per month to approximately 150 international customers such as Amazon, Apple, Inditex, AliExpress, Nike and Nespresso.

The challenge

- Loose coupling of multiple links, need to achieve integrated management

- Full process automation with timeliness, cost and efficiency

Our solution

S series, P series

Customer value

- For the first time, "last-mile picking" and "overstock picking" are carried out simultaneously

- 1000+ shipments per hour

- 99.99% order fulfillment accuracy rate

From Shelf-to-person to PopPick, Geek+ empowers Zongteng to intelligently upgrade its global warehouses

The customer

As a cross-border logistics service provider, we provide standardized and customized end-to-end supply chain solutions for first-haul trunking, global warehousing and distribution, and after-sales returns. Since its establishment, Zongteng Group has completed the international network layout in Europe, the United States, Australia and Asia, and its service capacity has been continuously improved, with the overseas warehouse area reaching 1.2 million square meters in the industry.

The challenge

- Difficult to recruit and expensive to employ overseas

- Higher standards for timeliness

- Highly flexible and stable solutions are needed to cope with business changes

- High compliance requirements for patents and certifications in overseas markets

Our solution

Shelf-to-person, P800, PopPick

Customer value

- Smoothly respond to the flood of the promotion and promote sales growth

- Significant reduction in warehouse operations staff

- New employee training reduced to 30 minutes

- Bringing high efficiency and satisfaction to logistics services

Geek+ and CJ Logistics lead the upgrade of 3PL smart logistics in Korea

The customer

CJ Logistics has rich practical experience in the logistics industry and a logistics network covering the whole of Korea. Through continuous international expansion, CJ Logistics has a business network consisting of 154 legal entities covering 35 countries, providing customers with comprehensive logistics services such as contract logistics, freight forwarding and international express delivery.

The challenge

- Surge in order volume

- Increased customer demand for timeliness of product delivery

- Operational efficiency needs to be improved

- Business needs to expand rapidly

Our solution

P series

Customer value

- Provide customers with 24/7 service in a space of about 10,000 square meters

- Achieves an average daily processing of 30,000 orders and a 33% increase in operational efficiency

- Effectively reduces personnel movement and significantly improves picking efficiency and accuracy

- Gizika's Korea office provides localized service and rapid response to customer needs

%20(1).png?width=80&height=80&name=3PL_0001_ups-1%20(2)%20(1).png)