Featured Case Studies

Case Studies

.png?width=80&height=80&name=Manufacturing_0008_BMW%20(1).png)

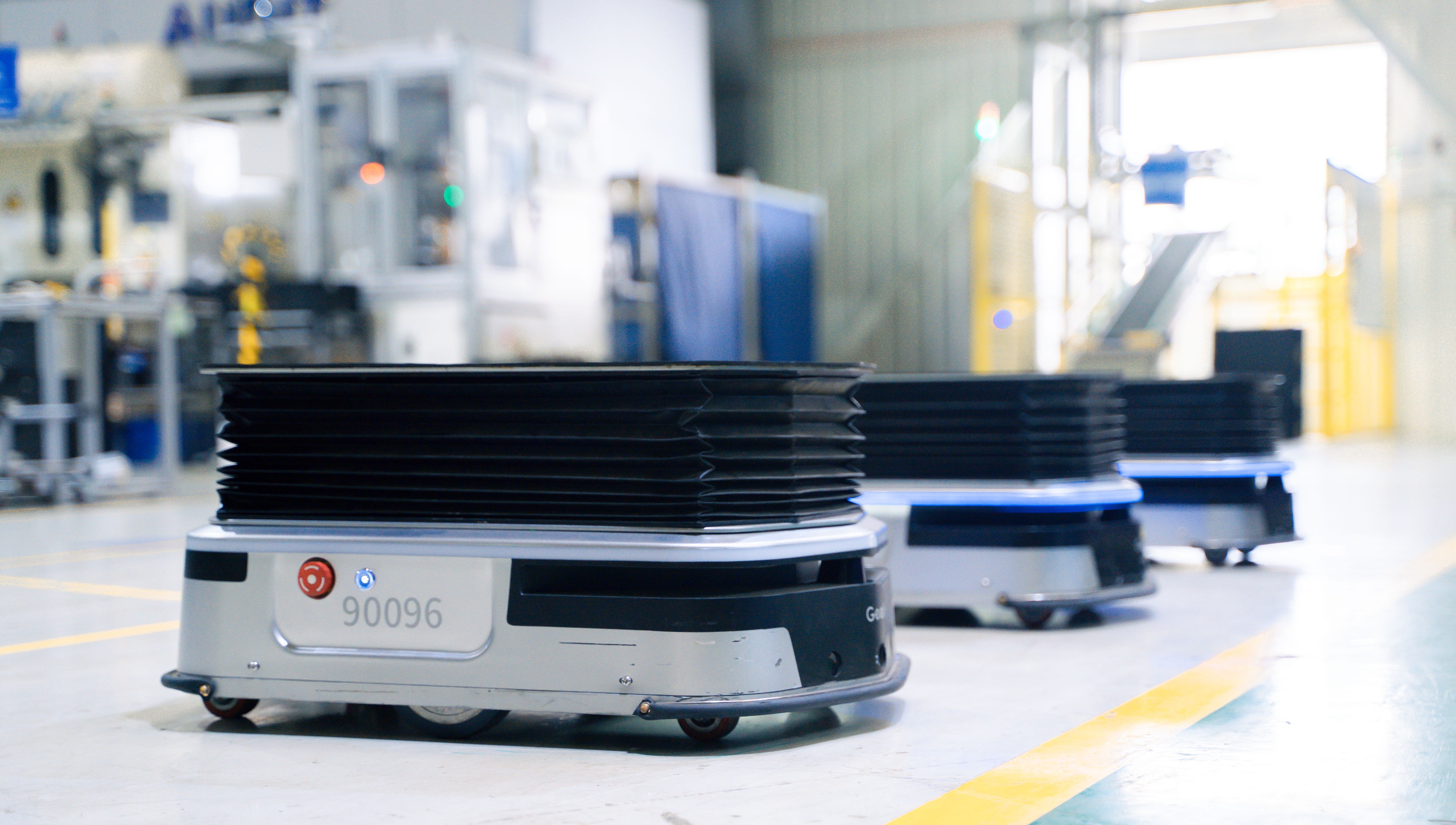

Infios and Geekplus drive efficiency in hardware manufacturing industry at Deutsche Telekom

The Customer

-

One of the world's leading integrated telecommunications companies: more than 261 million mobile customers, 25 million fixed-network lines, and 22 million broadband customers.

-

Deutsche Telekom is present in more than 50 countries. With a staff of some 200,000 employees throughout the world, generated revenue of 115.6 billion Euros in the 2024 financial year.

-

The B2B hardware distribution hub, supplying branches and enterprise customers. It manages 2,200 SKUs with a total stock of 2.5 million units.

The Challenge

- Digitalize B2B hardware logistics to improve efficiency, scalability, and working conditions.

- Reduce unnecessary walking and repetitive manual tasks in inbound and outbound processes.

- Replace outdated logistics technology after only 18 months of planning and development.

Our Solution

As general contractor, Infios deployed an integrated software and robotics solution, centered on the Geekplus Shelf-To-Person P1200 system.

-

- Autonomous Mobile Robots (AMRs) transport shelves of up to 1,200 kg directly to picking and packing stations.

- Manual walking is eliminated, while put-to-light and pick-to-light systems ensure accuracy in order fulfillment.

- Designed throughput: 30 inbound positions per hour and 100 outbound positions per hour, with easy scalability by adding robots or stations.

- All logistics flows are orchestrated by the Infios Unified Control System (UCS), seamlessly integrated into Deutsche Telekom’s IT landscape..

The Geekplus impact

Through Geek+ technology, Infios successfully transformed the Hanover distribution center:

- Operational efficiency: Significant improvement in inbound and outbound speed with minimized human error.

- Workplace ergonomics and safety: Staff relieved from monotonous and physically demanding tasks, improving conditions and reducing risks.

- Scalability and adaptability: Modular and compact solution that can be scaled to meet growing demand with minimal effort.

- Modernization of logistics: Complete replacement of outdated technology with a future-proof, automated system.

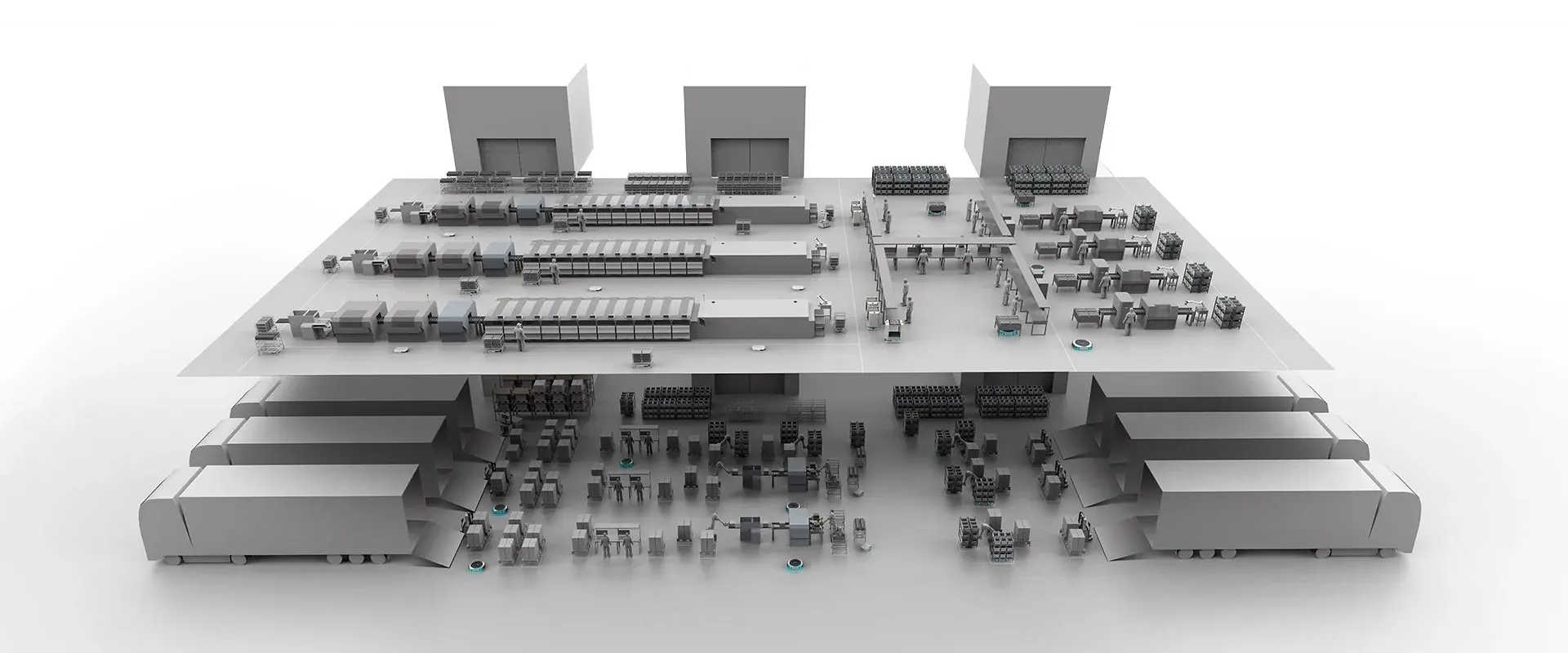

Geek+ Smart Factory: Setting a New Standard for Automated, Efficient Manufacturing

The Customer

The Geek+ Smart Factory system is at the forefront of manufacturing automation. Its AMRs connect diverse production scenarios, transforming traditionally static operations into dynamic and agile processes. Smart Factory solutions are designed to meet the diverse needs of global manufacturing facilities, enabling operations in industries ranging from electronics to automotive.

The Challenge

Manufacturers face significant challenges in today’s competitive landscape:

- Production Bottlenecks: Aging conveyor-based systems limit operational flexibility and struggle to keep up with growing production demands.

- Complex Product Portfolios: Managing multi-category production lines requires adaptable and scalable processes.

- Inefficient Resource Utilization: High costs and waste often stem from outdated systems and lack of operational visibility.

- Demands for Exceptional Quality: Clients increasingly expect high product quality and manufacturing traceability.

Our Solution

The Geek+ Smart Factory system delivers an end-to-end automation solution, transforming manufacturing sites into fully digitalized, streamlined operations.

- Advanced AMR Deployment: AMRs replace traditional conveyor systems, introducing flexible, decentralized production “islands” for greater agility than linear workflows. Deployment is carried out in strategic phases to ensure uninterrupted production, optimize robotic placement for workflow efficiency, address bottlenecks, and ultimately enable factories to double their production capacity.

- IoT and 5G Connectivity: Industrial IoT and 5G are leveraged for real-time data transmission and synchronization across the manufacturing floor, supporting precise initiation, tracking, and reporting of tasks.

- Edge Computing and MES Integration: Manufacturing Execution Systems (MES) combined with edge computing allow real-time control, seamless machine-to-machine communication, and detailed production oversight. Each implementation is customized to the client's unique industrial requirements.

- 3D Vision Technology: All AMRs feature advanced 3D vision systems, supporting autonomous navigation, object recognition, and manipulation, even in the most complex, multi-product environments.

The Geekplus impact

The Geek+ Smart Factory system delivers a comprehensive automation solution that transforms manufacturing sites into digital, streamlined operations with minimal disruption and clear, measurable gains.

- Efficiency Gains: Single-shift production efficiency increases by 33% to 67%, with reduced idle time and minimized production waste.

- Superior Quality Control: Assembly pass rates exceed 98%, ensuring products are delivered with consistent, exceptional quality.

- Cost Reduction: Material traceability reaches up to 95%, improving inventory management and reducing operational expenses.

- Versatility and Scalability: The system easily manages multi-category production lines and scales rapidly to suit urgent or high-volume orders.

Video

Geek+ and Assurant Elevate Risk Management with Robotics Solutions

The Customer

Assurant, a global leader in risk management solutions, specializes in protecting consumer goods and ensuring seamless customer experiences. With its deep expertise and innovative strategies, Assurant has set the standard for safeguarding assets and enhancing operational efficiency. By integrating advanced technologies into its processes, Assurant continues to redefine how businesses mitigate risk and deliver value to their customers.

Video

Geek+ and Systemex Automation Partner to Revolutionize Robotics in North America

The Customer

Systemex Automation is a leading Canadian systems integrator specializing in the engineering, manufacturing, and integration of advanced automation solutions for diverse industries. With a vision to deliver innovative robotics to its manufacturing, distribution, and retail customers across North America, Systemex Automation partnered with Geek+ to access a world-class autonomous mobile robot (AMR) portfolio and enhance its capabilities as a trusted solutions provider.

The Challenge

- Escalating labor shortages were causing operational bottlenecks and limiting growth potential for Systemex Automation's clients.

- Rising operational costs placed additional pressure on margins, demanding more efficient processes.

- Diverse customer needs for scalable, flexible automation tailored to existing warehouse workflows complicated solution design.

- The need to quickly adapt to changing order volumes and market dynamics called for future-proof, easily integrated robotics.

Our Solution

Geek+ and Systemex Automation worked together to deliver a comprehensive response to these industry demands:

- Integrated AMR Portfolio: Geek+ supplied Systemex Automation with an extensive range of AMR solutions, including picking, moving, sorting, and storage/ASRS systems, to tackle all stages of warehouse logistics.

- Seamless Deployment: Systemex Automation leveraged its systems integration expertise to ensure smooth implementation of Geek+ robotics, enabling minimal disruption and maximum compatibility with existing operations.

- Tailored Rollouts and Training: Joint planning allowed phased deployments based on client-specific needs, with collaborative training programs preparing staff to efficiently manage new robotic systems.

- Continuous Support: Ongoing assistance from both partners guaranteed successful adoption and long-term reliability for customers.

The Geekplus impact

Systemex Automation’s partnership with Geek+ has delivered transformative benefits to its client base:

- Boosted Operational Efficiency: Automated solutions have streamlined warehouse workflows, elevating accuracy and reducing order fulfillment times.

- Reduced Operating Costs: Reliance on manual labor decreased, while workplace inefficiencies were minimized, resulting in measurable savings.

- Alleviated Labor Constraints: Robotics have enabled customers to scale rapidly and adapt to labor market fluctuations, driving competitive advantage.

- Scalable Flexibility: The modular AMR solutions allow seamless expansion and customization as business needs evolve.

Video

Geek+ and BMW Brilliance : Advancing Automotive Manufacturing through Smart Logistics Collaboration

The Customer

BMW Brilliance Automotive Ltd., established in May 2003, is a joint venture between BMW Group and Brilliance Automotive Group Holdings. The company handles research and development, purchasing, production, sales, and after-sales services for BMW-brand automobiles in China. Brilliance BMW focuses on high-quality development and sustainability, aiming to become a provider of premium personal mobility services while driving sustainable practices across China's automotive value chain.

The Challenge

-

Increasing complexity and variety of automotive components (SKUs)

-

Difficulties in inventory management for small and medium-sized parts

-

Need for efficient, secure, and stable picking processes

-

Complex logistics environment requiring advanced, high-performance solutions

Our Solution

To address these challenges, BMW Brilliance implemented Geek+'s standard "goods-to-person" picking solution, an AI-driven system designed to optimize logistics operations and improve overall efficiency.

- P800R Picking Robots : These robots were deployed to optimize the picking process in the general assembly workshop, specifically for F-koli (small parts) logistics areas.

- Advanced Software Integration : Seamless integration with BMW Brilliance’s warehouse management system enabled real-time inventory tracking, precise order fulfillment, and data-driven decision-making.

- Comprehensive Staff Training : Geek+ provided thorough training programs to ensure that staff could safely and efficiently operate the new automated systems.

- Scalability and Flexibility : The solution was designed to be scalable, allowing BMW to expand or adapt the system as production volumes or SKU complexity grows.

The Geekplus impact

The implementation of Geek+'s innovative logistics solution delivered impressive results for BMW:

- 400% Increase in Picking Efficiency : Streamlined operations drastically improved productivity and minimized internal workflows' bottlenecks.

- 64% Reduction in Labor Costs : Automation reduced manual tasks, freeing up human resources for higher-value activities.

- 99.99% Picking Accuracy : With the help of AI and robotics, nearly error-free picking processes were achieved, boosting inventory reliability.

- Energy Optimization : A significant reduction in overall energy consumption contributed to Brilliance BMW's sustainability goals.

- System-Wide Integration : The digitalized solution ensured full connectivity and synchronization across all logistics links, enhancing operational transparency and control.

“This project is an important step in BMW Brilliance’s move towards smart manufacturing and digital factories, and a key milestone in our logistics transformation! I like to call it ‘collaborative innovation.’ We worked closely with Geek+ to develop an efficient and flexible smart logistics solution, which not only realized the integration and coherence of the warehouse management system, but also provided us with more flexible and faster solutions for future upgrades and renovations, setting a model of a people-oriented sustainable green factory for the industry.”

Ralf Schieder, Vice President of BMW Brilliance Automotive Strategy and Logistics

Video

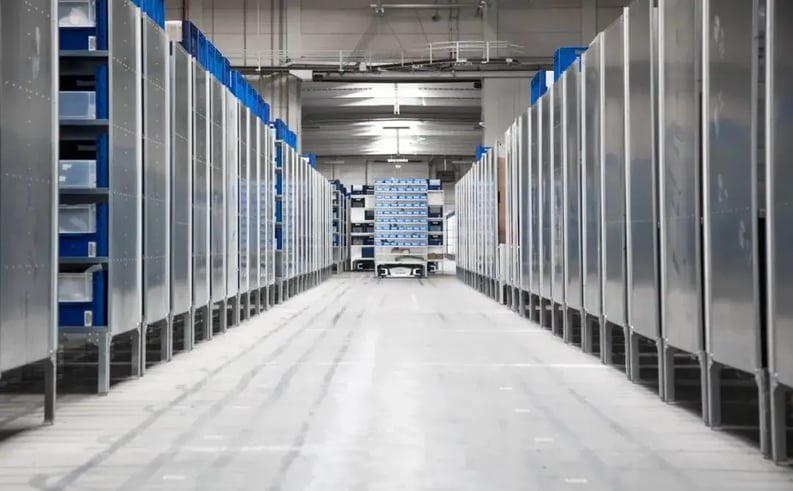

153 AMRs in 15,000 square meters warehouse, German manufacturing leader OEG in 3 months to achieve the transformation

The Customer

OEG is a global specialist in advanced heating, ventilation and air conditioning, supplying German wholesalers and manufacturers as well as the international market with the components needed for heating, ventilation and air conditioning systems.

The Challenge

- 15,000 sq. ft. warehouse with over 80,000 kinds of parts, access efficiency needs to be improved

- High demand for shelving due to the large number of specialized products and different size SKUs

- To cope with the order flood and business expansion, high flexibility solution is needed

Our Solution

Goods-to Person, P800

Customer value

- Go live within 3 months without production downtime

- Customized shelves flexibly adapt to customer needs

- Easily cope with order floods

- Effectively manage operating costs

Leading the way in Four-way Shuttle solution for more than six months, Tica builds a digital smart production base

The customer

Founded in 1991, Tica is committed to becoming the world's leading system supplier and service provider of intelligent environment and green energy. After 31 years of innovative development, its leading products have been the first in the national market share for 12 consecutive years, and its products are widely used in projects such as Bird's Nest, Water Cube, C919 large aircraft, big rocket, Baihetan Hydropower Station, etc.

The challenge

- Traditional manual efficiency and accuracy to be improved

- Warehouse capacity needs to be improved

- Need to ensure information pull-through and product stability without stopping

Our solution

Four-way Shuttle Solution

Customer value

- Significant increase in warehouse utilization

- Improved operational efficiency

- Human-machine mixing is safe and reliable

- Full manufacturing process information pull-through

Siemens Switchgear Use a Robot Army to Achieve a 350% Efficiency Leap

About Customer

Shanghai Siemens Switchgear is a core node in Siemens’s global supply chain, specializing in medium-voltage switchgear production. With a focus on innovation and lean digitalization, the company operates a state-of-the-art facility in Shanghai, China, and plays a pivotal role in Siemens’s global manufacturing strategy.

The Challenge

- Managing a vast, complex SKU portfolio.

- Manual operations limiting efficiency and response time.

- Space constraints hindering storage capacity.

- Implementing automation without disrupting production.

- No existing solutions for discrete manufacturing needs.

Our Solution

- Solution Deployed: End-to-end warehouse-to-production automation.

- Robotic Integration: 100+ robots, including P800, RS/C, X-series, and MP1000R.

- System Integration: Integrated with WMS, MES, and SAP for real-time data.

- Spatial Optimization: 60% footprint reduction, 300% storage increase.

.png?width=788&height=440&name=Untitled%20design%20(2).png)

The Geek+ impact

- Efficiency: 350% increase in operational efficiency.

- Accuracy: Near-perfect materials accuracy on the production line.

- Storage Utilization: 300% increase in site storage capacity.

- Safety: Human-centered design with advanced safety systems and ergonomic improvements.

Video

Geek+ M100 robots streamline Yanfeng’s manufacturing process

The Customer

Yanfeng is a world leader in automotive interiors focused on product development, system integration, and design. Since 2010, Yanfeng has expanded its global presence and is currently operating over 230 factories worldwide with over 65,000 employees, and 6,700 employees dedicated to development and design. By providing the automotive industry with first-class products and services, Yanfeng aims to redefine the way people relax, work and play inside their vehicles.

The Challenge

- Low efficiency of moving materials to production line

- Difficulties managing inventory

- Long material transportation path

- Labor-intensive operations due to frequent manual transfer of materials

- Difficulties visualizing the manufacturing flow and high error rates

Our Solution

- Geek+ provides Yanfeng with moving robots M100 for transferring raw materials to production lines

- Connecting Geek+ Moving System (GMS) to WMS and MES, enabling real-time visibility of the manufacturing process

The Geek+ impact

- Reduced labor costs

- 99% Material handling accuracy

- Real-time monitoring of manufacturing process

Video

Konica Minolta streamlines manufacturing process with both picking and moving solutions

The customer

Konica Minolta is a Japanese multinational technology company headquartered in Tokyo, with offices in 49 countries worldwide. The company manufactures business and industrial imaging products, including copiers, laser printers, multi-functional peripherals (MFPs) and digital print systems for the production printing market.

The challenge

- Konica was looking for an AMR solution to achieve higher accuracy of materials handling in its warehouse and replace its magnetic stripe AGVs which offer little flexibility, are subject to low operating efficiency, and lead to high maintenance costs.

- Production line consists of more than 30,000 different materials, it is costly to manage the inventory and accuracy.

- High frequency of material delivery, low efficiency of manual material delivery, poor timeliness, and high labor-intensity.

Our solution

- 10 P800 robots in the warehouse and make use of Geek+ iWMS , for precise management of materials

- 3 M100 robots featuring SLAM navigation at the production line to deliver the materials from warehouse to production line

- Geek+ Moving System (GMS) receives task from iWMS and deliver the materials to production line automatically.

The Geek+ impact

- Improved inventory accuracy

- Stock-taking frequency reduced by 92%

- Material delivery efficiency increased by 31~42%

- Storage area saved by more than 32%

- Reduced labor intensity

Video

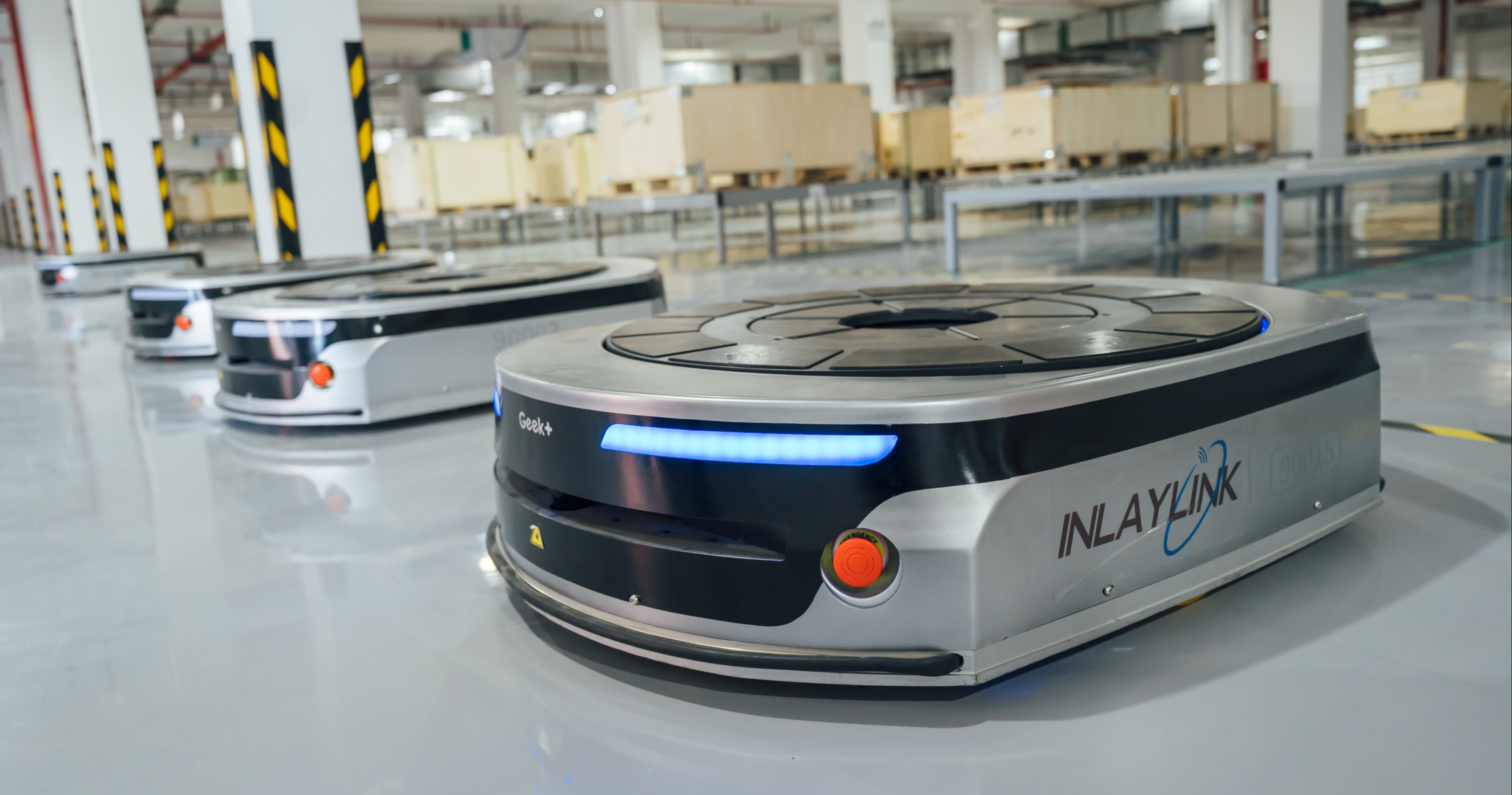

INLAYLINK factory realizes a smart upgrade with moving robots

The Customer

INLAYLINK is one of the world-renowned manufacturers of RFID tag antennas, specializing in the design, research and development, production, and sales of RFID tag antennas. It is also one of the few high-tech companies that can provide RFID data collection solutions and has won many world-known rewards.

The Challenge

- On-site materials are moved across floors and multiple areas frequently, and manual handling cannot guarantee the timeliness

- Manual handling is labor-intensive

- The value of a single material on-site is high. Checking, verification, signing, and handover are required for the delivery, online, offline, and warehousing links.

- The efficiency is low and the management cost is high.

- An information system is required to connect the warehouse and the production line to achieve physical and automatic docking of accounts.

Our Solution

- The site is equipped with 12 M1000 robots that transfers the materials out of the warehouse and sends them to the production lines.

- The robots are connected with vertical warehouse stackers, elevators, access control, and other systems to realize automatic, accurate, and timely distribution of materials across floors and sectors.

- The Geek+ Moving System (GMS) is connected to WMS and MES, enabling real-time visibility of the manufacturing process.

The Geek+ impact

- The integration information allowed a reduction in material management costs by 60%

- Material handling efficiency increased by 30%

- Reduced labor-insensitive operations

Video

Why did Dell choose Geek+’s picking solutions to upgrade its warehouse?

Geek+ innovatively integrated the rapid visual inventory feature in the ‘goods to person’ picking system, improving the inventory management.

The customer

Kerry Logistics is a third party logistics provider, warehouse operator and the oldest international freight services company in mainland China.

Dell is a multinational computer technology company that develops, repairs and supports computers and related products and services.

The challenge

Kerry Logistics manages and operates Dell’s Xiamen spare parts warehouse. The layout of the warehouse area is very compact, and the usage rate of the storage area is very high, which increases the difficulty of manual selection. The traditional manual picking efficiency cannot meet the timeliness of Dell’s outbound storage requirements.

Our solution

- Geek+ deployed 32 P500 picking robots and over 2,000 sets of shelves

- A dense storage method was implemented to meet high storage capacity and high space utilization requirements

- The solutions allows to manage massive SKUs and the solution is highly flexible, functions such as picking, loading, and inventory can be switched at any time according to business needs

The Geek+ impact

- Single package inventory efficiency multiplied by 10 with the integration of a fast visual inventory device

- Entirely open and unmanned process, optimizing space utilization

- The number of on-site operators has been reduced, and the timeliness and accuracy of the overall operation has been improved, saving labor and management costs

.png)