Featured Case Studies

Case Studies

.png?width=80&height=80&name=Manufacturing_0008_BMW%20(1).png)

Geek+ and Hessing Revolutionize Food Logistics with Robotics

The Customer

Hessing Supervers has been a trusted name in fresh produce processing for over 50 years. Specializing in ready-to-cook vegetables, processed fruits, and meal salads, Hessing supplies retail chains, fast-food outlets, and inflight caterers across the Netherlands, Belgium, Germany, and Denmark. Handling millions of packages weekly, the company sought to modernize operations to keep pace with growing demand and maintain its commitment to freshness and quality.

The Challenge

Operating in the highly competitive fresh food market, Hessing faced several operational challenges:

- Complex Workflow Management: Their Greenport Venlo site required seamless coordination across washing, mixing, and packaging zones.

- Time Sensitivity: With fresh produce having limited shelf life, delays in processing and distribution could lead to increased food waste and cost inefficiencies.

- Scalability Needs: Rising demand for pre-packaged fruits and vegetables necessitated a logistics solution capable of efficient scaling.

- Employee Safety and Productivity: Managing a three-story facility posed increased risks and physical demands on employees.

Our Solution

Hessing turned to Geek+ to implement a state-of-the-art logistics system designed to meet these challenges head-on. Key features of the solution included:

- 112 Geek+ M200 Robots: These autonomous mobile robots connected distinct processing areas and ensured seamless movement of goods across floors.

- AI-Driven Fleet Management: Utilizing advanced algorithms, the central AI monitored hundreds of robots simultaneously to optimize routes, reduce traffic congestion, and ensure peak performance.

- 3D Obstacle Detection: Robots were equipped with sensors to identify and safely bypass obstacles, maintaining the highest safety standards for employees and products.

- Three-Story Operation Integration: The AMRs operated on multiple levels, ensuring end-to-end coverage of the distribution process while optimizing vertical space utilization.

- Streamlined Food Processing Workflow: The system enabled faster transitions between washing, mixing, and packaging stations, minimizing hold-ups and preserving the freshness of produce.

The Geekplus impact

The new system delivered outstanding results for Hessing, including:

- Efficiency Gains: Robots transformed workflow efficiency, enabling faster processing times and timely produce delivery.

- Reduced Food Waste: The intelligence-driven logistics minimized delays, ensuring higher percentages of products reached consumers in peak condition.

- Fresher Produce: Accelerated movements through the supply chain enabled retailers to enjoy longer product shelf lives.

- Enhanced Safety and Productivity: Employees reported improved working conditions due to reduced physical strain and optimized facility operations.

- Scaled Operations: The innovative system positioned Hessing to expand its operations in response to rising demand without adding logistical bottlenecks.

“By automating our distribution center with Geek+’s moving solutions, we’ve made our ‘factory of the future’ vision a reality. We now bring healthier food to consumers faster and with less waste—an achievement we are truly proud of.”

Hans Hessing, Director Center of Excellence, Hessing Supervers

Video

Geek+ and JJCL Transform Cold Chain Logistics with SkyCube Automation

The Customer

The Customer

JJCL (Jinjiang Cold Logistics) is a regional leader in temperature-controlled logistics across Asia. Managing 11 cold storage facilities with a total capacity exceeding 560,000 m³, JJCL serves industries like food, groceries, and pharmaceuticals. Known for its deep-freeze capabilities and logistics innovation, JJCL ensures strict quality and temperature management standards for its clients.

The Challenge

JJCL faced several operational pain points that limited its ability to meet rising demands:

- Manual Operations Inefficiencies: Traditional pallet handling in frozen and chilled zones slowed down processes and reduced throughput.

- Storage Constraints: Limited storage density in sub-zero environments posed capacity challenges.

- Safety Risks: Harsh working environments, such as -18°C zones, brought significant safety concerns for workers.

- Demand for Speed and Accuracy: Customers expected fast, precise deliveries, which JJCL’s current systems struggled to meet.

Our Solution

To address these challenges, JJCL implemented Geek+’s SkyCube Pallet-to-Person system, a cutting-edge solution tailored to the needs of cold chain logistics. Key components included:

- Multi-Zone Automation: Robotic operations managed tasks across temperature zones, from -18°C frozen areas to +5°C chilled storage.

- Integrated Technologies: X1200 four-way shuttles, MP1000R robotic movers, and high-speed lifts seamlessly transported and processed pallets.

- Vertical Storage Enhancement: Automated systems optimized vertical space usage for a 70% capacity increase.

- Intelligent Orchestration: A unified software platform facilitated precise task allocation, ensuring efficient operations and minimizing errors.

- 24/7 Operations: The automated workflow functioned continuously without interruptions, even during transitions between temperature zones.

The Geekplus impact

With the SkyCube system, JJCL experienced transformational results:

- Expanded Storage Capacity: A 70% increase in storage density allowed JJCL to stock more inventory without expanding facility requirements.

- Accelerated Picking Efficiency: A 190% boost in picking speed streamlined order fulfillment, meeting customer expectations for fast delivery.

- Enhanced Accuracy: The system achieved 99.99% picking accuracy, ensuring high-quality service and minimizing errors.

- Improved Worker Safety: Manual operations in freezing conditions were replaced with automation, significantly reducing risks to employees.

- Sustainability and Scalability: JJCL achieved 24/7 operations, prepared for increasing demand, and reduced inefficiencies, positioning itself as a market leader in logistics innovation.

Video

S&S Activewear: Revolutionizing Apparel Warehousing with the PopPick Solution

The Customer

Founded in 1988 and headquartered in Bolingbrook, Illinois, S&S Activewear is a technology-driven distributor of apparel and accessories, serving the United States and Canada. With a product portfolio spanning over 80 brands, including Adidas and American Apparel, S&S caters to a diverse customer base, including retail brands, e-commerce companies, apparel decorators, promotional product distributors, entertainment merchandise dealers, lifestyle brands, and online custom apparel platforms. The company operates over 4 million square feet of warehouse space across North America, ensuring efficient distribution and delivery.

The Challenge

S&S faced several operational challenges as they scaled their business:

- Optimizing Employee Productivity: Ensuring efficient use of labor resources in a large-scale warehouse environment.

- Improving Order Quality: Maintaining high accuracy in order fulfillment to meet customer expectations.

- Enhancing Delivery Efficiency: Reducing lead times to ensure timely deliveries.

- Addressing Rapid Business Growth: Scaling operations to handle increasing order volumes and customer demands.

Our Solution

To address these challenges, S&S implemented Geek+’s PopPick Goods-to-Person solution. Key features of the solution included:

- Deployment of 340 AMR Robots: These robots automated the movement of goods within the warehouse, reducing manual labor and increasing efficiency.

- 24 PopPick Workstations: These workstations streamlined the picking process, enabling faster and more accurate order fulfillment.

- 2 Inbound/Outbound Workstations: Automated systems for seamless integration with conveyor lines, optimizing inbound and outbound operations.

The Geekplus impact

The implementation of the PopPick solution delivered significant value to S&S’s operations:

- Enhanced Picking Efficiency and Accuracy: The automated system significantly improved the speed and precision of order picking.

- Increased Processing Capacity: The warehouse now processes up to 4,500 order lines per hour, meeting high customer demand.

- Optimized Delivery Speed: Faster order processing and seamless integration with conveyor systems reduced lead times.

- Scalable Operations: The solution provided the flexibility to handle future growth and increased order volumes.

Video

Soccer.com and Geek+: Transforming Sports Retail Logistics with Robotics Innovation

The Customer

Soccer.com is a leading online retailer specializing in soccer gear, apparel, and equipment. Catering to players, coaches, and fans, the platform offers a wide range of products, including jerseys, cleats, balls, and training accessories from top global brands. Known for its commitment to the soccer community, Soccer.com also provides customization services, exclusive team gear, and resources to support players at all levels.

Video

Shop LC and Geek+: Transforming E-Commerce Logistics with Smart Automation Solutions

The Customer

Shop LC is a prominent home shopping network and online retailer offering a wide range of affordable luxury products, including jewelry, fashion, beauty, home goods, and lifestyle items. Known for its unique "Low Cost" approach, Shop LC provides exceptional value to customers while supporting sustainability and charitable initiatives through its "Your Purchase Feeds" program, which helps fight hunger globally.

Video

Transforming SP Digital’s Supply Chain with Geek+ and Boreal Automation

The Customer

SP Digital, a leading e-commerce company based in Chile, faced significant challenges managing massive spikes in demand brought on by the COVID-19 pandemic. To tackle these issues, SP Digital partnered with Geek+ and Boreal to implement an advanced robotics solution tailored to optimize their supply chain.

The Challenge

The COVID-19 pandemic drove a surge in online shopping, leaving SP Digital struggling to manage unprecedented demand for computer hardware and gaming products. Their existing supply chain faced inefficiencies in picking processes and warehouse throughput, making it difficult to keep up with the rapid changes in order volumes. To maintain customer satisfaction and sustain business growth, SP Digital sought a robust, efficient, and scalable solution.

Our Solution

Geek+ collaborated with Boreal to deliver a dynamic robotics solution that addressed SP Digital’s challenges. Key components of the implementation included:

- AI-Driven AMRs Geek+ integrated intelligent autonomous mobile robots to automate and optimize the picking processes within SP Digital's warehouses.

- Advanced Picking Robotics Boreal supported the deployment of advanced picking systems, tailored to handle SP Digital’s specific needs.

- Seamless Collaboration Geek+ and Boreal worked closely to ensure a smooth implementation process, minimizing disruptions while maximizing the operational impact.

This combination of smart robotics and collaborative integration resulted in a scalable, efficient, and data-driven warehouse solution.

The Geekplus impact

The deployment of Geek+ AMRs, combined with Boreal's expertise, delivered measurable outcomes:

- Optimized Warehouse Operations Streamlined processes enabled SP Digital to handle rapid shifts in order volumes while maintaining operational stability.

- Maximum Picking Efficiency Robotic automation improved picking speeds, significantly reducing turnaround times and enhancing overall throughput.

- Scalability During Peak Seasons The solution empowered SP Digital to meet massive spikes in demand without compromising accuracy or delivery timelines.

"For us, implementing Geek+ robotics systems in our value chain is an important step towards enriching and strengthening the services we offer our clients. We are very satisfied with the work done together with Boreal and Geek+. The transformation has been remarkable, and we look forward to further collaboration."

Diego Santander, CEO, SP Digital

Video

Geek+ and Systemex Automation Partner to Revolutionize Robotics in North America

The Customer

Systemex Automation is a leading Canadian systems integrator specializing in the engineering, manufacturing, and integration of advanced automation solutions for diverse industries. With a vision to deliver innovative robotics to its manufacturing, distribution, and retail customers across North America, Systemex Automation partnered with Geek+ to access a world-class autonomous mobile robot (AMR) portfolio and enhance its capabilities as a trusted solutions provider.

The Challenge

- Escalating labor shortages were causing operational bottlenecks and limiting growth potential for Systemex Automation's clients.

- Rising operational costs placed additional pressure on margins, demanding more efficient processes.

- Diverse customer needs for scalable, flexible automation tailored to existing warehouse workflows complicated solution design.

- The need to quickly adapt to changing order volumes and market dynamics called for future-proof, easily integrated robotics.

Our Solution

Geek+ and Systemex Automation worked together to deliver a comprehensive response to these industry demands:

- Integrated AMR Portfolio: Geek+ supplied Systemex Automation with an extensive range of AMR solutions, including picking, moving, sorting, and storage/ASRS systems, to tackle all stages of warehouse logistics.

- Seamless Deployment: Systemex Automation leveraged its systems integration expertise to ensure smooth implementation of Geek+ robotics, enabling minimal disruption and maximum compatibility with existing operations.

- Tailored Rollouts and Training: Joint planning allowed phased deployments based on client-specific needs, with collaborative training programs preparing staff to efficiently manage new robotic systems.

- Continuous Support: Ongoing assistance from both partners guaranteed successful adoption and long-term reliability for customers.

The Geekplus impact

Systemex Automation’s partnership with Geek+ has delivered transformative benefits to its client base:

- Boosted Operational Efficiency: Automated solutions have streamlined warehouse workflows, elevating accuracy and reducing order fulfillment times.

- Reduced Operating Costs: Reliance on manual labor decreased, while workplace inefficiencies were minimized, resulting in measurable savings.

- Alleviated Labor Constraints: Robotics have enabled customers to scale rapidly and adapt to labor market fluctuations, driving competitive advantage.

- Scalable Flexibility: The modular AMR solutions allow seamless expansion and customization as business needs evolve.

Video

Xtep and Geek+ Enhance Logistics with Smart Warehouse Solutions

The Customer

Xtep Group is an internationally renowned sports shoe and apparel brand with a rapidly expanding footprint, Xtep required a robust logistic solution to keep pace with customer demands and ensure operational agility during fluctuating market conditions.

The Challenge

- Surge in international orders driven by global expansion.

- Seasonal apparel trends necessitating adaptable logistics systems.

- Large SKU varieties requiring advanced storage and inventory solutions.

- Inefficiencies during high-demand periods led to slower picking and bottlenecks.

Our Solution

Geek+ implemented its state-of-the-art RoboShuttle® tote-to-person picking solution tailored to Xtep's requirements:

- Dual-Robot Collaboration: RS robots optimized vertical storage use, while P40 robots facilitated high-speed order picking and delivery.

- Dynamic Picking Operations: Dual picking points at workstations ensured operators could continuously pick without delays.

- Smart Inventory Arrangement: Frequently ordered items were stored on lower, easily accessible racks to accelerate picking speed.

- Flexible Load Management: Compatibility with bins and cartons of all sizes minimized operational costs.

- Scalable and Rapid Deployment: New robots could be seamlessly added during peak periods to meet increased demand.

The Geekplus impact

Xtep's adoption of Geek+'s advanced logistics technology delivered remarkable results:

- 3x Growth in Picking Efficiency: Streamlined workflows and reduced operational delays.

- 5x Increase in Storage Density: Maximizing warehouse space with vertical optimization, saving on rental costs.

- Accelerated Implementation: Quick deployment with minimal disruption to existing operations.

- Cost Savings through Sustainability: Recycling original storage boxes reduced expenses and improved operational processes.

- Future-Proof Scalability: The system's adaptable design ensured readiness for ongoing business growth.

“Xtep is well aware that digital transformation is the key to breaking through development bottlenecks and reshaping the sustainable growth momentum of its business. Therefore, we are committed to promoting the deployment of digital technologies both online and offline. Through our collaboration with Geek+, we have successfully applied logistics robot technology to achieve warehouse transformation in an efficient and low-carbon manner, accelerating the realization of the Five-Five Plan goals and sustainable growth.”

Jun Lin, Assistant Vice President, Xtep

Video

Rollship and Geek+ Transform E-Commerce Order Fulfillment in Hong Kong

The Customer

Rollship, backed by Chun Sing, has over 20 years of experience managing logistics for the e-commerce sector. Known for its customer-first approach, Rollship specializes in addressing the unique complexities of online retail. Seeking to enhance their operational capabilities, Rollship collaborated with Geek+ to revolutionize their order fulfillment processes in Hong Kong.

The Challenge

- E-Commerce Industry Pressure: Rising demand for faster and more accurate order fulfillment necessitated smarter operations.

- High-Volume Order Management: Handling an increasing number of SKUs demanded a solution to sustain capacity without compromising speed.

- Limited Integration: The need for seamless integration with existing warehouse management systems (WMS) and enterprise resource planning (ERP) platforms.

- Scalability and Seasonal Fluctuations: A logistics partner capable of adapting to changing order volumes and seasonal surges.

Our Solution

Geek+ implemented a range of advanced solutions to address Rollship's challenges:

- PopPick Goods-to-Person Solution: Mobile robotics paired with moveable shelves to enhance picking efficiency, enabling quick fulfillment of orders.

- Four-Way Shuttle System: A high-density storage solution for managing an extensive SKU variety while maximizing warehouse capacity.

- RoboShuttle Tote-to-Person System: Optimized vertical storage and retrieval capabilities, improving throughput and accuracy.

- Seamless Integration: Geek+ software integrated with WMS, ERP, and MES systems, ensuring efficiency without overhauling existing infrastructure.

- Scalability and Flexibility: Systems designed to handle fluctuations in demand, with quick adaptability to seasonal peaks like holidays or major campaigns.

The Geekplus impact

The collaboration resulted in substantial value for Rollship:

- Enhanced Fulfillment Accuracy: Advanced robotics reduced picking errors, ensuring higher customer satisfaction.

- Optimized Space Utilization: High-density storage improved facility use, accommodating more inventory efficiently.

- Significant Efficiency Gain: Automation streamlined operations, boosting order processing speeds and reducing bottlenecks.

- Adaptability for Growth: The scalable system allowed Rollship to confidently expand its operations in line with market demand.

- Integration with Existing Operations: A smooth transition with compatible systems preserved business continuity during

Video

Maersk Revolutionizes Supply Chain Operations with AGV Technology in HK

The Customer

- Maersk is a global leader in logistics and supply chain solutions, renowned for its commitment to excellence, innovation, and sustainability. With a network spanning over 130 countries, Maersk ensures seamless shipping and warehousing operations for millions of businesses globally.

- As part of its strategic focus on innovation, Maersk leverages cutting-edge technology to optimize supply chain operations and meet evolving customer needs.

The Challenge

- Inefficiencies in manual processes: Traditional pick-and-pack operations were time-consuming and resource-intensive, particularly during high-demand periods.

- The need for accuracy: Ensuring error-free order fulfillment was critical to maintaining customer satisfaction.

- Workforce strain during peak seasons: Seasonal spikes in demand placed significant pressure on manpower resources.

Our Solution

- Enhanced speed and accuracy: The AGV system executed picking tasks faster than traditional methods while achieving 100% accuracy.

- Labor optimization: By automating repetitive and labor-intensive tasks, AGVs significantly reduced dependence on manual labor, especially during peak demand periods.

- Improved efficiency: The combination of automated parcel handling equipment and scanning technology streamlined the end-to-end process, creating a simplified and reliable system.

The Geekplus impact

- Faster operations: The AGV system completed tasks at a speed significantly higher than manual pick-and-pack processes.

- Error-free fulfillment: The automation achieved 100% picking accuracy, eliminating errors and enhancing customer satisfaction.

- Manpower savings: During peak periods, the AGVs reduced the need for additional labor, ensuring smooth operations without added costs.

- Scalability for growth: By introducing automation, Maersk empowered its distribution center to handle increased demand while setting the stage for broader innovation initiatives.

“With the increasing use of the new technology in our warehouse, we enter in a new era with a lot of potentials to optimize our operations. Comparing with the menu, pick and pack, the AGB enables us to perform the activities in the warehouse a lot better. ”

Caroline Wu, Managing Director, Greater China, Maersk

Geek+ and BMW Brilliance : Advancing Automotive Manufacturing through Smart Logistics Collaboration

The Customer

BMW Brilliance Automotive Ltd., established in May 2003, is a joint venture between BMW Group and Brilliance Automotive Group Holdings. The company handles research and development, purchasing, production, sales, and after-sales services for BMW-brand automobiles in China. Brilliance BMW focuses on high-quality development and sustainability, aiming to become a provider of premium personal mobility services while driving sustainable practices across China's automotive value chain.

The Challenge

-

Increasing complexity and variety of automotive components (SKUs)

-

Difficulties in inventory management for small and medium-sized parts

-

Need for efficient, secure, and stable picking processes

-

Complex logistics environment requiring advanced, high-performance solutions

Our Solution

To address these challenges, BMW Brilliance implemented Geek+'s standard "goods-to-person" picking solution, an AI-driven system designed to optimize logistics operations and improve overall efficiency.

- P800R Picking Robots : These robots were deployed to optimize the picking process in the general assembly workshop, specifically for F-koli (small parts) logistics areas.

- Advanced Software Integration : Seamless integration with BMW Brilliance’s warehouse management system enabled real-time inventory tracking, precise order fulfillment, and data-driven decision-making.

- Comprehensive Staff Training : Geek+ provided thorough training programs to ensure that staff could safely and efficiently operate the new automated systems.

- Scalability and Flexibility : The solution was designed to be scalable, allowing BMW to expand or adapt the system as production volumes or SKU complexity grows.

The Geekplus impact

The implementation of Geek+'s innovative logistics solution delivered impressive results for BMW:

- 400% Increase in Picking Efficiency : Streamlined operations drastically improved productivity and minimized internal workflows' bottlenecks.

- 64% Reduction in Labor Costs : Automation reduced manual tasks, freeing up human resources for higher-value activities.

- 99.99% Picking Accuracy : With the help of AI and robotics, nearly error-free picking processes were achieved, boosting inventory reliability.

- Energy Optimization : A significant reduction in overall energy consumption contributed to Brilliance BMW's sustainability goals.

- System-Wide Integration : The digitalized solution ensured full connectivity and synchronization across all logistics links, enhancing operational transparency and control.

“This project is an important step in BMW Brilliance’s move towards smart manufacturing and digital factories, and a key milestone in our logistics transformation! I like to call it ‘collaborative innovation.’ We worked closely with Geek+ to develop an efficient and flexible smart logistics solution, which not only realized the integration and coherence of the warehouse management system, but also provided us with more flexible and faster solutions for future upgrades and renovations, setting a model of a people-oriented sustainable green factory for the industry.”

Ralf Schieder, Vice President of BMW Brilliance Automotive Strategy and Logistics

Video

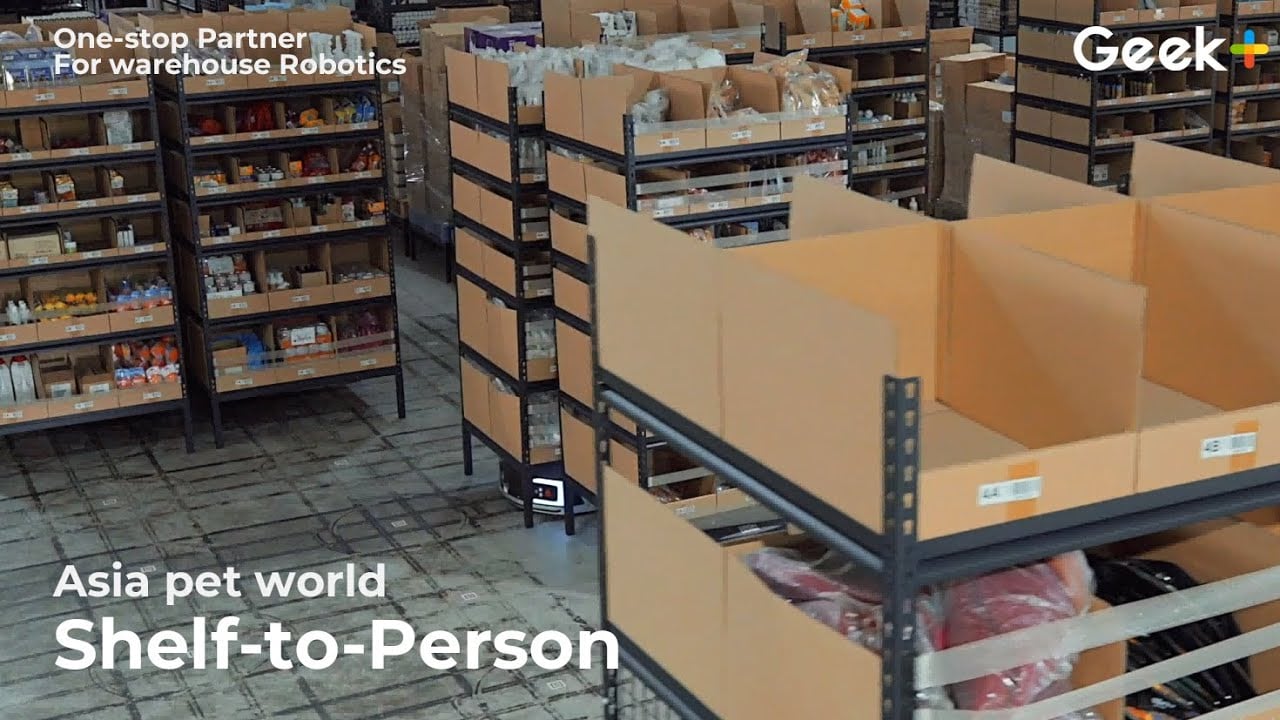

Asia PetWorld and Geek+ Collaborate to Revolutionize Warehousing in the Pet Supply Industry

The Customer

- Asia PetWorld, a global leader in pet supply distribution, handles 8,000 unique SKUs daily.

- Supplies a wide range of pet products, including large pet beds, cat litter, and bulk dog food.

- Operates in a labor-intensive and complex warehousing landscape with high product diversity.

The Challenge

- High SKU volume: Managing a vast assortment of 8,000 SKUs demanded significant labor and resources.

- Rising labor costs: Increasing operational expenses due to dependency on manual labor.

- Handling heavy, bulky items: Products such as large pet beds and bulk pet food added physical strain on workers.

- Labor shortages: Difficulties in maintaining efficient operations due to workforce shortages.

Our Solution

- Robots capable of efficiently handling bulky and heavy items, such as large pet beds, cat litter, and dog food.

- Improved inventory management through intelligent automation, enabling operational flexibility.

- Enhanced employee ergonomics by reducing the physical strain of manual tasks, fostering a safer and healthier work environment.

The Geekplus impact

- Efficient operations: A 99.5% picking accuracy leading to more reliable order fulfillment.

- Employee well-being: Reduced physical strain and created a safer, more comfortable work environment for workers.

- Rapid transformation: Warehouse operations were revolutionized within just two months.

- Scalable solution: The robotics system ensured flexibility for future growth and changes.

- Customer satisfaction: Enhanced inventory management improved overall customer service experience.

“In Singapore, the labor availability is always a challenge for warehouse owners. The situation is even worse for the pet industry where workers often need to manage heavy, awkward items. After adopting the Geek+ robots, we are better able to handle our stocks and can offer a more comfortable workplace to our employees.”

Sebastian Wiradharma, Director, Asia PetWorld

Video

.jpg)

.jpg)

-1.jpg?width=200&height=66&name=Hessing%20Corporate%20SV%20logo%2070cm(1)-1.jpg)