Featured Case Studies

Case Studies

THG Fulfil and Geekplus Unite to Create a Peak Season Hero

The Partner

THG PLC is a vertically integrated, digital first consumer brands group that operates three distinct businesses in Beauty, Nutrition and Ingenuity, each scaled from the UK to hold global leading positions in their respective sectors.

THG Ingenuity provides cutting-edge ecommerce solutions for clients designed to accelerate brand growth. It comprises THG Commerce, a complete commerce solution with the highest performing technology platform in market THG Fulfil, a provider of world-class fulfilment engineered to improve customer retention, and THG Studios, an award-winning creative agency providing a range of services from campaigns and content creation to videography and photography. With its expertise in building direct to consumer brands, Ingenuity is uniquely positioned to bring pertinent, pragmatic, and global know-how across all aspects of commerce.

The Challenge

In the fast-paced world of e-commerce, peak seasons such as Black Friday, Cyber Monday, and the holiday rush present both opportunities and challenges for retailers. Efficient order fulfillment becomes critical to capitalize on increased demand while maintaining customer satisfaction.

Our Solution

Recognizing this, THG Fulfil and Geekplus joined forces to develop a robust solution that would transform peak season operations into a seamless, scalable, and highly efficient process. This collaboration resulted in the creation of a "Peak Season Hero," a comprehensive strategy that leveraged advanced technology and expertise to navigate the complexities of high-volume order fulfillment.

The Geekplus impact

The Geekpus solution joins THG Fulfil’s already extensive warehouse automation solutions, which it leverages to serve the growing trend for late-night shopping by offering a 1 a.m. Next Day Delivery cut-off service for its brands including ESPA and LOOKFANTASTIC, alongside third-party clients.

This innovative order fulfilment solution deployed has helped THG to increase efficiency and enhance customer satisfaction while at the same time enabling scalability and providing real-time data and analytics through an innovative software platform. The expansion of automation solutions now enables THG Fulfil to support category-agnostic items of any size through its automation solutions, pushing 95% of all units sold through a form of automation.

Video

Geek+ and Carrefour Transform Retail Logistics with Robotics Innovation

The Customer

Carrefour, a global leader in the retail industry, operates thousands of stores across over 30 countries, serving millions of customers daily. Renowned for its forward-thinking approach, Carrefour has consistently embraced innovation to enhance every aspect of its operations. By committing to cutting-edge technology in supply chain and logistics, the company continues to revolutionize retail, ensuring seamless, efficient, and customer-centric experiences.

Video

Geek+ and KPI Solutions Help Outdoor Network Boost Efficiency

The Customer

Outdoor Network, a major U.S. distributor of vehicles and OEM parts, faced critical operational challenges, including consolidating multi-line orders across two facilities, labor shortages, and the need to enhance efficiency to meet peak-season demands. Partnering with Geek+ and KPI Solutions, Outdoor Network deployed innovative mobile robotic solutions at their East Coast Distribution Center in Albany, Georgia.

The Challenge

Outdoor Network encountered multiple hurdles in its warehouse operations:

- The need to consolidate multi-line orders from two separate facilities.

- Ongoing labor shortages due to heightened demand for their products.

- A pressing requirement to enhance operational efficiency to cope with peak demands.

These challenges hindered Outdoor Network's ability to maintain high service levels and operational agility, demanding a scalable and efficient solution.

Our Solution

Geek+ and KPI Solutions collaborated to design and implement an advanced automation strategy tailored to Outdoor Network’s needs:

- Integration of Mobile Robotic Solutions: Mobile robots were deployed to handle oversized items, efficiently managing putaway to static shelving and pallet racks.

- Streamlined Picking Operations: Robots transported oversized picks in carts to a dedicated consolidation area for outbound shipping.

- Optimized Single Facility Approach: By merging storage and picking processes into one consolidated facility, operations were simplified and streamlined.

This solution leveraged smart automation to boost storage capacity and efficiency while addressing labor challenges through reduced dependency on manual tasks.

The Geekplus impact

- Increased Efficiency: Streamlined operations with mobile robots reduced order processing time and improved overall workflow.

- Enhanced Storage Capacity: Optimized use of warehouse space by consolidating storage and picking processes into a single facility.

- Labor Optimization: Reduced reliance on manual labor, addressing labor shortages and improving workforce productivity.

- Improved Order Accuracy: Automated processes minimized errors in order picking and consolidation.

- Scalability: The solution provided a flexible and scalable framework to handle peak demands and future growth.

- Cost Savings: Lowered operational costs by reducing manual tasks and improving space utilization.

Video

Geek+ and Körber Help Ariat Transform Supply Chain

The Customer

Ariat International, a leading equestrian and performance footwear and apparel brand, grappled with significant challenges in its supply chain, including labor shortages, pressure to optimize warehouse throughput, and the physical toll on associates. Collaborating with Körber and Geek+, Ariat implemented a cutting-edge robotics solution featuring 88 autonomous mobile robots (AMRs), integration with Körber's K.Motion Warehouse Advantage (WMS), and 2,000 additional racks in their expansive 1 million sq. ft warehouse.

The Challenge

Ariat experienced a surge in customer demand while facing industry-wide labor shortages. Their massive 1 million sq. ft warehouse also posed challenges such as optimizing storage capacity, maximizing throughput, and reducing the physical strain on their warehouse associates due to extensive walking and repetitive manual tasks. To maintain high levels of customer satisfaction, Ariat needed to introduce a scalable and highly efficient solution to transform its supply chain operations.

Our Solution

Geek+ and Körber partnered to implement a cutting-edge robotics solution tailored to Ariat's challenges.

- Robotic Deployment: Geek+ provided 88 AI-driven AMRs designed to automate and streamline picking processes.

- Enhanced Integration: Körber’s K.Motion Warehouse Advantage (WMS) was integrated to ensure seamless interaction between robots, racking systems, and existing warehouse management processes.

- Storage Expansion: 2,000 racks were added to optimize space utilization and enhance throughput within Ariat’s facility.

This solution moved associates away from repetitive manual workloads, allowing them to focus on higher-value tasks while significantly increasing efficiency across the supply chain.

The Geekplus impact

The collaboration between Ariat, Geek+, and Körber yielded impressive results that transformed Ariat’s supply chain operations:

- Improved Efficiency: Warehouse picking efficiency and accuracy experienced significant enhancements, directly impacting speed and reducing errors.

- Associate Productivity Advance: Productivity doubled, with a 100% increase noted following the implementation.

- Reduced Walking Strain on Associates: Associate walking decreased by 82%, minimizing workplace fatigue and improving employee satisfaction.

- Compliance with Demand Surges: The scalability of Geek+’s robots ensured Ariat could effectively meet demand spikes without operational bottlenecks.

"Geek+’s AMRs allow us to move our employees away from repetitive tasks and towards more rewarding activities, resulting in a better working environment and bringing greater value to the services we provide our customers."

Matt Hardenberg, VP of Distribution, Ariat International

Video

Geek+ Helps Winit Streamline Warehouse Operations

The Customer

Winit is dedicated to creating a borderless online shopping community, offering fast, reliable, and sustainable supply chain management. Operating warehouses in multiple regions, including the United States, Winit supports major e-commerce players like eBay. However, managing a wide range of inventory, addressing operational inefficiencies, and accommodating the surge in demand became critical challenges at their Cincinnati fulfillment center.

The Challenge

The Cincinnati fulfillment center faced increasing complexity due to a high variety of SKUs, frequent employee turnover, and a rapidly growing influx of online orders. Ensuring accurate and timely order fulfillment while scaling operations to meet demand was becoming increasingly difficult. Winit needed an innovative and sustainable solution capable of optimizing warehouse operations while maintaining cost-effectiveness.

Our Solution

Geek+ provided a tailored robotic solution to resolve Winit’s operational challenges. Key elements of the solution included:

- Deployment of 150 P800 robots for automating inventory management and streamlining workflows.

- 16 picking stations strategically placed to maximize process efficiency.

- 6 one-point stations, enabling streamlined operations in a 6,200 square meter warehouse area.

This advanced robotics integration was seamlessly implemented, ensuring minimal disruption. The versatile P800 robots coupled with efficient station configurations empowered Winit to scale effectively while maintaining high levels of operational accuracy.

The Geekplus impact

The implementation delivered significant, measurable benefits:

- 200%-300% Increase in Efficiency Manual operations were replaced with agile robotics, drastically enhancing productivity and reducing turnaround times.

- Workforce Optimization The solution reduced the reliance on a large number of operators, enabling smoother, more streamlined workforce management.

- 99% Operational Accuracy The precision of robotic automation ensured near-perfect order fulfillment, significantly boosting customer satisfaction.

Video

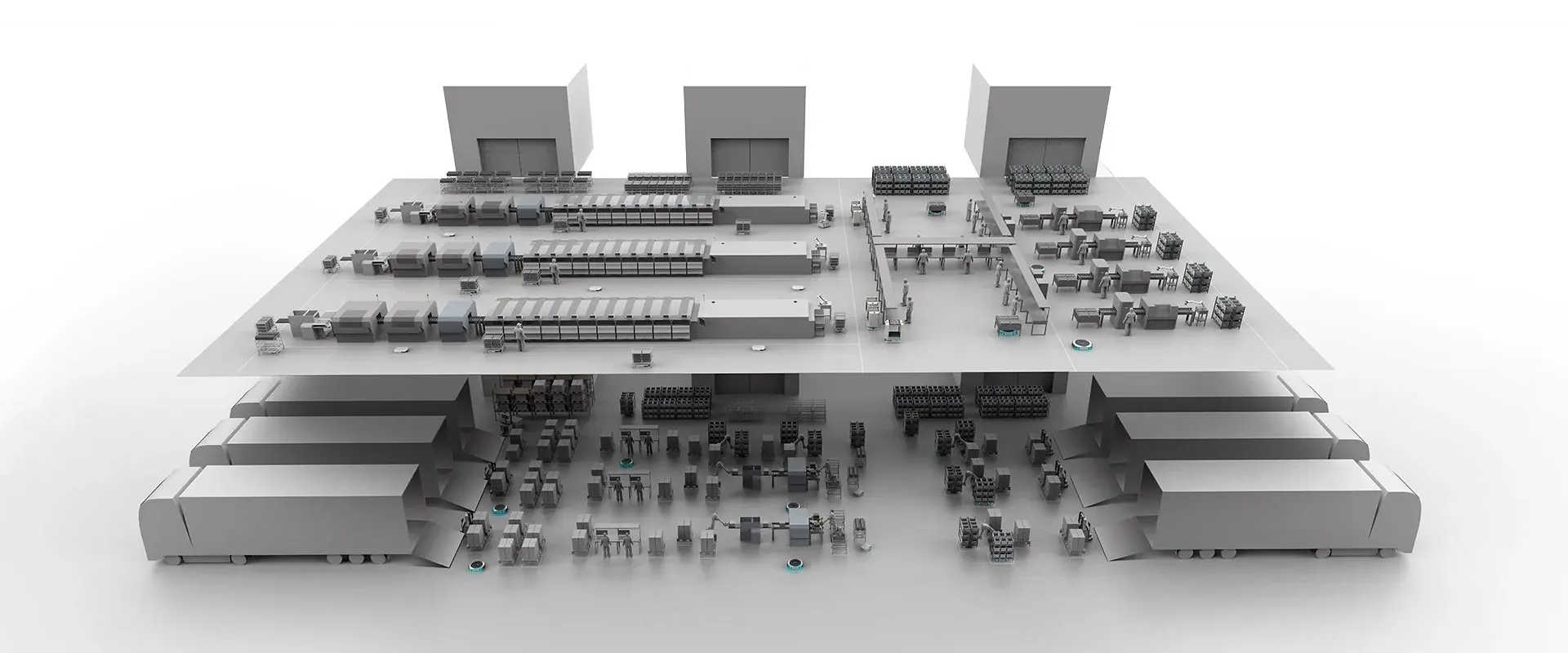

Geek+ Smart Factory: Setting a New Standard for Automated, Efficient Manufacturing

The Customer

The Geek+ Smart Factory system is at the forefront of manufacturing automation. Its AMRs connect diverse production scenarios, transforming traditionally static operations into dynamic and agile processes. Smart Factory solutions are designed to meet the diverse needs of global manufacturing facilities, enabling operations in industries ranging from electronics to automotive.

The Challenge

Manufacturers face significant challenges in today’s competitive landscape:

- Production Bottlenecks: Aging conveyor-based systems limit operational flexibility and struggle to keep up with growing production demands.

- Complex Product Portfolios: Managing multi-category production lines requires adaptable and scalable processes.

- Inefficient Resource Utilization: High costs and waste often stem from outdated systems and lack of operational visibility.

- Demands for Exceptional Quality: Clients increasingly expect high product quality and manufacturing traceability.

Our Solution

The Geek+ Smart Factory system delivers an end-to-end automation solution, transforming manufacturing sites into fully digitalized, streamlined operations.

- Advanced AMR Deployment: AMRs replace traditional conveyor systems, introducing flexible, decentralized production “islands” for greater agility than linear workflows. Deployment is carried out in strategic phases to ensure uninterrupted production, optimize robotic placement for workflow efficiency, address bottlenecks, and ultimately enable factories to double their production capacity.

- IoT and 5G Connectivity: Industrial IoT and 5G are leveraged for real-time data transmission and synchronization across the manufacturing floor, supporting precise initiation, tracking, and reporting of tasks.

- Edge Computing and MES Integration: Manufacturing Execution Systems (MES) combined with edge computing allow real-time control, seamless machine-to-machine communication, and detailed production oversight. Each implementation is customized to the client's unique industrial requirements.

- 3D Vision Technology: All AMRs feature advanced 3D vision systems, supporting autonomous navigation, object recognition, and manipulation, even in the most complex, multi-product environments.

The Geekplus impact

The Geek+ Smart Factory system delivers a comprehensive automation solution that transforms manufacturing sites into digital, streamlined operations with minimal disruption and clear, measurable gains.

- Efficiency Gains: Single-shift production efficiency increases by 33% to 67%, with reduced idle time and minimized production waste.

- Superior Quality Control: Assembly pass rates exceed 98%, ensuring products are delivered with consistent, exceptional quality.

- Cost Reduction: Material traceability reaches up to 95%, improving inventory management and reducing operational expenses.

- Versatility and Scalability: The system easily manages multi-category production lines and scales rapidly to suit urgent or high-volume orders.

Video

GXO and Geek+ Revolutionized Warehouse Operations for a Leading French Sports Retailer

The Customer

GXO is recognized worldwide for its expertise in outsourced logistics and supply chain solutions, delivering tailored strategies to address the dynamic needs of its clients across various industries. This project focused on supporting the logistics network of a leading French sports retailer, a brand renowned for its wide range of products and a heavy reliance on efficient e-commerce order fulfillment.

The Challenge

The French sports retailer faced several operational challenges tied to its growing market demands:

- Rising e-commerce expectations: Increasing consumer demand for rapid order fulfillment highlighted the need for higher picking accuracy and efficiency.

- Storage Constraints: Managing diverse inventory efficiently within the existing warehouse layout was becoming increasingly difficult.

- Seasonal Demand Peaks: Ensuring seamless operations during high-volume periods such as sales promotions and holiday seasons created logistical bottlenecks.

Our Solution

To resolve these challenges, GXO and Geek+ collaborated to deploy an innovative goods-to-person solution powered by 500 autonomous mobile robots in the 12,000-square-meter facility.

- Integrated Robot Systems: The deployment included RS robots, capable of elevating goods to shelves as high as 40 feet to maximize storage density. P40 robots efficiently transported bins along the warehouse floor and delivered them to designated workstations for picking.

- High-Density Storage Design: The warehouse layout was restructured for optimal bin storage, enabling the robots to handle up to 70,000 bins.

- Scalability and Adaptability: The modular design of the automation solution allowed for seamless scaling of operations without interrupting ongoing activities. This structure enabled the warehouse to efficiently handle fluctuating order volumes during seasonal peaks.

The Geekplus impact

The success of this project underscored the strategic value of integrating advanced robotics into warehouse operations:

- Operational Excellence: The streamlined processes improved overall efficiency, allowing GXO to provide superior service to its client.

- Customer Satisfaction:mFaster, error-free order fulfillment bolstered the retailer’s reputation and reinforced trust among its customers.

- Future-Proofing: The scalable and adaptable system positioned the retailer for continued growth and market responsiveness.

“Geek+'s goods-to-person solution has transformed our warehouse operations, significantly enhancing picking efficiency, storage capacity, and adaptability. This deployment underscores our commitment to using advanced robotic technology to address the complexity of global supply chains.”

Rui Marques, General Manager, GXO France

Video

Geek+ and Assurant Elevate Risk Management with Robotics Solutions

The Customer

Assurant, a global leader in risk management solutions, specializes in protecting consumer goods and ensuring seamless customer experiences. With its deep expertise and innovative strategies, Assurant has set the standard for safeguarding assets and enhancing operational efficiency. By integrating advanced technologies into its processes, Assurant continues to redefine how businesses mitigate risk and deliver value to their customers.

Video

Geek+ and MedicAir Revolutionize Life-Saving Operations with Robotics

The Customer

MedicAir is a leader in the production and distribution of medical devices and home care support services, dedicated to improving the quality of life for patients. Through its Ventilotherapy unit, MedicAir delivers critical therapies such as oxygen treatment, mechanical ventilation, and artificial nutrition. Its logistics operations are essential to ensuring life-saving supplies reach patients on time, making efficiency and reliability non-negotiable priorities.

The Challenge

MedicAir faced numerous challenges in its logistics operations, which were directly tied to the high stakes of delivering life-saving therapies. These included:

- High-Volume Deliveries: Managing 600 shipments daily for over 100,000 patients required impeccable precision and reliability.

- Demand for Error-Free Operations: Even minor errors or delays could jeopardize lives.

- Operational Inefficiencies: Manual picking processes led to slower workflows and limited scalability in response to peak demand.

- Flexibility Requirements: Seasonal increases in orders and sudden spikes needed immediate adaptability without compromising service levels.

Our Solution

- Fleet of 15 AMRs from Geek+: Advanced AMRs (Autonomous Mobile Robots) model P800 transported shelves directly to operators, reducing unnecessary movement and increasing efficiency; robots were coordinated via Geek+’s Robot Management System (RMS), ensuring seamless operations and optimal route management.

- Shelf-to-Person Model: Instead of requiring workers to travel to retrieve items, shelves are brought to stationary operators at three designated picking stations, streamlining picking and put-away.

- Integrated Warehouse Management: Geek+’s Warehouse Control System (WCS) works in tandem with MedicAir’s Warehouse Management System (WMS), streamlining inventory tracking and fulfillment.

- Collaboration with Industry Experts: Eurofork and Moveo Servizi designed and deployed a fully customized system, aligning robotics and workflow enhancements with MedicAir’s specific operational needs.

The Geekplus impact

The implementation of Geek+ robotics technology delivered exceptional results for MedicAir, including:

- Improved Productivity: Increased picking capacity to handle up to 90 simultaneous orders and 30 ongoing tasks per station.

- Enhanced Efficiency: Productivity soared to processing up to 130 order lines per hour, peaking at 200.

- Error-Free Fulfillment: The shelf-to-person model eliminated manual picking errors, ensuring error-free deliveries critical to patient safety.

- Operational Flexibility: The modular setup allowed rapid scaling by adding AMRs during peak seasons, ensuring uninterrupted service.

- ROI Achieved in Under Three Years: A cost-efficient system with significant long-term savings brought rapid returns on investment for MedicAir.

“From the precision and punctuality of our deliveries depends literally the lives of our patients. The Geek+ solution maximized efficiency, increased flexibility, and improved productivity. It’s a game-changer for MedicAir.”

Elena Pagani, Supply Chain Manager, MedicAir

Geek+ and Hunkemöller Redefine Warehouse Efficiency with Robotics on a Mezzanine

The Customer

Hunkemöller is a global leader in the lingerie and retail industry, with an extensive presence across Europe. Known for its stylish products and customer-centric approach, the brand has consistently embraced innovation to improve operations. The Almere warehouse in the Netherlands serves as a critical hub for fulfilling orders efficiently while maintaining the high service standards that Hunkemöller’s customers expect.

The Challenge

To meet the growing demands of e-commerce while managing space limitations, Hunkemöller faced several challenges, including:

- Space Constraints: A need to utilize the full vertical height of their warehouse efficiently.

- Demanding Order Fulfillment: The pressure to streamline and scale operations due to increasing order volumes.

- Maximizing Automation Potential: A requirement for a solution that integrates technology seamlessly while adhering to sustainability goals.

Our Solution

Hunkemöller partnered with Geek+ to implement a forward-thinking warehouse automation system that addressed these challenges head-on:

- Fleet of 160 Geek+ Robots: Equipped with advanced features, these AMRs optimized movement and storage on the mezzanine floor.

- 8.6-Meter-High Mezzanine: The innovative installation leveraged vertical space, proving that AMRs can operate efficiently at impressive heights.

- Order Picking Optimization: Enhanced speed and precision in item retrieval ensured faster and more accurate processing.

- Smart Storage Utilization: The solution prioritized smarter storage organization, reducing wasted space and increasing productivity.

- Sustainable Infrastructure: Built on a sustainable mezzanine floor, provided by Anera B.V., aligning with Hunkemöller’s environmental responsibility goals.

The Geekplus impact

By integrating Geek+’s robotics technology, Hunkemöller realized significant benefits, including:

- Higher Efficiency: Streamlined order picking processes boosted operational speed and accuracy.

- Space Maximization: The automated solution unlocked previously underutilized vertical warehouse space.

- Scalability: The modular system enables adjustments to accommodate seasonal demand increases.

- Customer-Centric Outcomes: Enhanced fulfillment operations ensured better customer satisfaction and loyalty.

- Sustainability: The mezzanine installation underscored Hunkemöller’s commitment to eco-friendly practices.

Video

Geek+ and Dr.Max Streamline E-Commerce Operations with Robotics

The Customer

Dr.Max is a leading pharmaceutical retailer in Romania and Central Europe, managing an extensive portfolio of products ranging from over-the-counter (OTC) medicines to cosmetics and dietary supplements. Its e-commerce operations serve a growing customer base, consistently ranking among Romania’s top 10 websites in terms of unique visitors. With its commitment to quality and innovation, Dr.Max sought to elevate its logistics capabilities to meet surging online demand while ensuring precision in delivering medical goods that directly impact patient well-being.

The Challenge

Dr.Max faced several critical challenges in scaling its e-commerce distribution operations:

- High Order Volume: Managing a diverse inventory of over 25,000 SKUs and processing them efficiently to meet customer expectations.

- Demanding Accuracy Requirements: Achieving near-perfect order fulfillment was vital in delivering essential medical supplies to patients.

- Growth Pressures: Rapidly growing online sales and seasonal peaks necessitated a flexible solution capable of scaling operations seamlessly.

- Waste Management: Minimizing product waste caused by expired inventory further complicated the logistical complexities.

Our Solution

To address these challenges, Geek+ introduced its cutting-edge goods-to-person AMR technology to Dr.Max’s Bucharest warehouse. The solution included:

- Deployment of Nearly 100 AMRs: These robots work tirelessly around the clock, retrieving items from storage and delivering them to picking stations with exceptional efficiency.

- Enhanced Picking System: Geek+ AMRs optimized batch processing, minimizing the need for special orders while considering key factors like expiration dates to reduce inventory waste.

- Scalable Operations: The modular AMR system allows Dr.Max to easily add robots to accommodate seasonal peaks and long-term business growth.

- Advanced Algorithms and Software: Integrated intelligence prioritizes order consolidation, ensuring faster fulfillment while maintaining order accuracy above 99%.

The Geekplus impact

The partnership with Geek+ delivered significant value to Dr.Max’s operations, including:

- Improved Efficiency: The AMRs operate 24/7, ensuring rapid and reliable order processing to keep up with customer demand.

- Enhanced Storage Utilization: Optimized handling of SKUs increased the warehouse’s capacity, accommodating more products without requiring additional space.

- Unmatched Accuracy: Over 99% fulfillment accuracy reduced errors, ensuring timely and precise deliveries to patients.

- Scalability and Flexibility: The ability to expand the AMR fleet provided future-proofing against demand fluctuations.

- Sustainability Improvements: Efficient inventory management reduced product waste, supporting environmental goals.

“Geek+ technology has provided us with a clearer view of our processes and allowed us to meet our patients’ needs more effectively than ever before. Their solutions are a vital part of our logistics strategy as we continue to grow.”

Sorin David, Supply Chain Director, A&D Pharma - Dr.Max Group

Video

Geek+ and Dr.Max Transform Fulfillment with Tote-to-Person Robotics

The Customer

Dr.Max is the largest pharmacy network in Central and Eastern Europe, renowned for its expansive catalog of health and wellness products, including medication, cosmetics, and dietary supplements. With nearly 3,000 outlets and robust e-commerce capabilities, Dr.Max has become a trusted name for consumers seeking reliable and fast access to essential goods. Their new facility in Telgate, Italy is dedicated to e-commerce fulfillment, further extending their ability to deliver products to customers efficiently via home delivery or click-and-collect services.

The Challenge

Operating in a highly competitive and regulated industry, Dr.Max faced a series of escalating challenges:

- Rapid E-Commerce Growth: A 55% increase in online revenue in 2023 placed immense pressure on logistics operations.

- Expanding Product Portfolio: Handling a wide range of goods, including pharmaceutical items and cosmetics, required sophisticated inventory management.

- Faster Delivery Expectations: Meeting customer demands for quick home delivery and pharmacy pickups demanded operational agility.

- Scalability Needs: The growing number of orders required a solution that could adapt to increasing volumes seamlessly.

Our Solution

To address these challenges, Geek+ and SSI Schaefer implemented an advanced Tote-to-Person solution tailored to Dr.Max’s specific requirements. The key components of the solution included:

- 8-Meter-High Shuttle Robot: Facilitating vertical storage and maximizing warehouse space to accommodate a broad product portfolio.

- Fulfillment Robots: Supporting fast and accurate picking of items for efficient order processing.

- Integration with SSI Schaefer Components: Combining robotics with robust logistical infrastructure for a seamless and scalable system.

- Ergonomic Workstations and Intuitive Software: Creating an operator-friendly solution that enhances productivity while reducing physical strain on employees.

- Automated Processes: Including order picking, carton sealing, and shipment preparation for streamlined operations.

The Geekplus impact

The implementation of Geek+ Tote-to-Person technology provided Dr.Max with several measurable benefits:

- Enhanced Efficiency: Automation significantly reduced order processing time, ensuring rapid fulfillment.

- Space Optimization: The vertical storage system improved warehouse capacity without requiring additional physical space.

- Scalability: The flexible system allows for quick adjustments to meet seasonal peaks and growing e-commerce demands.

- Improved Employee Experience: Ergonomic and user-friendly design eased workloads and improved operational accuracy.

- Industry Leadership: The integration positioned Dr.Max as a front-runner in adopting cutting-edge logistics technologies within the pharmaceutical industry.

“Geek+’s mobile robots ensure quick and efficient order processing while providing ergonomic solutions for our employees. This implementation is a game-changer for us as we continue to grow.”

— Miguel Martins da Silva, Group Chief Supply Chain Officer, Dr.Max

Video

.png?width=200&height=200&name=images%20(1).png)

.png?width=200&height=142&name=images%20(2).png)