Featured Case Studies

Case Studies

Geek+ solutions improved Verte's warehouse throughput by 4x

About Customer

Verte is an AI cloud-based supply platform provider that connects, unifies, and automates commerce operations, powering retailers to sell wherever their customers are and focus on scalable growth.

The challenge

- Complex requirements across multi-sellers

- Needing to implement faster throughput for better customer satisfaction

Our Solution

- After purchasing 45 picking robots initially, Verte asked Geek+ to scale the solution to 130 picking robots and 3,000 racks in Verte's 750,000 sqft. warehouse in Georgia. Geek+ solutions enabled Verte to achieve greater warehouse productivity and meet rising consumer expectations.

The Geek+ impact

- Scaled throughput 4x times

- Implemented in less than 3 months

- Improved inventory storage and picking efficiency for both inbound and outbound fulfillment

- During peak season, Verte received over 250,000 units on the first shift with fewer than 50 staff-hours and didn't miss a single inbound or outbound service level agreement (SLA).

Video

Pharmaceuticals Company builds supply chain resilience with Tote-to-Person picking

About Customer

Founded in 1999 and headquartered in Wuhan, China, the company is responsible for the distribution of pharmaceutical formulation, TCM and herbs, medical devices, APIs, and more. With a broad domestic distribution network, the company is considered one of China’s leading pharmaceutical companies.

The challenge

- Labor-intensive operations and unsafe work environment

- Strict safety regulations due to COVID-19

- Need for more storage capacity

- Demand for highly accurate operations

Our Solution

- Eight tote-picking RS-2 robots were deployed on a 500 sqm storage area

- Installation of robot compatible shelving, including 3000 totes

The Geek+ impact

- Storage capacity improved by 200%

- Picking efficiency improved by 300%

- Picking accuracy improved by 99.99%

- Improved work environment compatible with current safety regulations

-1.png)

Catch.com.au improves services with over 100 AMRs

About Customer

Catch.com.au is one of Australia’s leading online retailers. Founded in 2006, they aim to bring new e-commerce solutions to Australia and support online shoppers with a wide range of brands and products at low prices. Purchased by Westfarmers Group in June 2019, they experienced rapid business growth.

The challenge

- Low warehouse storage efficiency cannot meet regular storage demands

- Rapid surge in demand

- Rapidly growing customer base with 30,000 new customers every week

- High expectations for fast and accurate deliveries

Our Solution

- Over 100 picking robots were deployed in Catch.com.au’s 2,000 sqm facility to manage an inventory of 80,000 SKUs

The Geek+ impact

- The ability to quickly expand operations in line with growth

- Improved picking efficiency; picking rates up to 2000 items / h

- Increased throughput capacity and speed of delivery

Siemens Switchgear Use a Robot Army to Achieve a 350% Efficiency Leap

About Customer

Shanghai Siemens Switchgear is a core node in Siemens’s global supply chain, specializing in medium-voltage switchgear production. With a focus on innovation and lean digitalization, the company operates a state-of-the-art facility in Shanghai, China, and plays a pivotal role in Siemens’s global manufacturing strategy.

The Challenge

- Managing a vast, complex SKU portfolio.

- Manual operations limiting efficiency and response time.

- Space constraints hindering storage capacity.

- Implementing automation without disrupting production.

- No existing solutions for discrete manufacturing needs.

Our Solution

- Solution Deployed: End-to-end warehouse-to-production automation.

- Robotic Integration: 100+ robots, including P800, RS/C, X-series, and MP1000R.

- System Integration: Integrated with WMS, MES, and SAP for real-time data.

- Spatial Optimization: 60% footprint reduction, 300% storage increase.

.png?width=788&height=440&name=Untitled%20design%20(2).png)

The Geek+ impact

- Efficiency: 350% increase in operational efficiency.

- Accuracy: Near-perfect materials accuracy on the production line.

- Storage Utilization: 300% increase in site storage capacity.

- Safety: Human-centered design with advanced safety systems and ergonomic improvements.

Video

ASDA launches UKs first national sortation project

About Customer

Asda Logistics Services is a hub of activity, with 39 nationwide distribution operations including 21 food depots, three clothing centers, two ambient GM hubs, two import centers, two dot.com fulfillment centers, and nine ASCs. Supporting distribution across five types of store formats as well as the delivery of parcels to customers’ homes and to store for Click and Collect, Asda Logistics Services distributes an estimated 800,000 deliveries to store and 20,000,000 deliveries to customers a year.

The challenge

- More customers shopping online, followed by surges in forward and reversed volume

- Boost Asda’s toyou e-commerce service to better serve customers

- Respond to fluctuating order volumes without having to invest in additional warehouse space.

Our Solution

- 60 Geek+ S20C robots were deployed on a sorting area of 360 sqm in Asda’s cross-docking facility.

Video

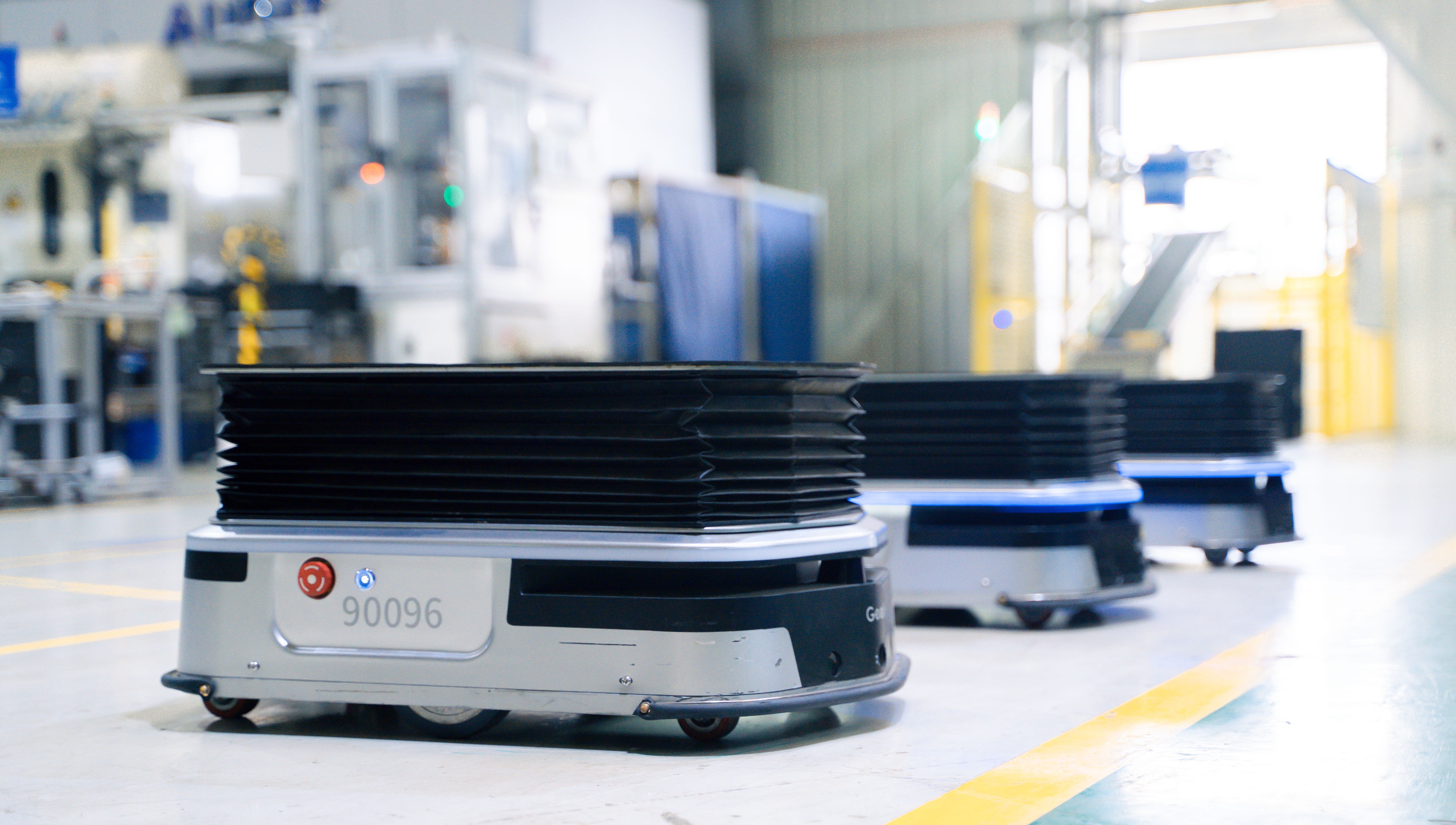

Geek+ M100 robots streamline Yanfeng’s manufacturing process

The Customer

Yanfeng is a world leader in automotive interiors focused on product development, system integration, and design. Since 2010, Yanfeng has expanded its global presence and is currently operating over 230 factories worldwide with over 65,000 employees, and 6,700 employees dedicated to development and design. By providing the automotive industry with first-class products and services, Yanfeng aims to redefine the way people relax, work and play inside their vehicles.

The Challenge

- Low efficiency of moving materials to production line

- Difficulties managing inventory

- Long material transportation path

- Labor-intensive operations due to frequent manual transfer of materials

- Difficulties visualizing the manufacturing flow and high error rates

Our Solution

- Geek+ provides Yanfeng with moving robots M100 for transferring raw materials to production lines

- Connecting Geek+ Moving System (GMS) to WMS and MES, enabling real-time visibility of the manufacturing process

The Geek+ impact

- Reduced labor costs

- 99% Material handling accuracy

- Real-time monitoring of manufacturing process

Video

Konica Minolta streamlines manufacturing process with both picking and moving solutions

The customer

Konica Minolta is a Japanese multinational technology company headquartered in Tokyo, with offices in 49 countries worldwide. The company manufactures business and industrial imaging products, including copiers, laser printers, multi-functional peripherals (MFPs) and digital print systems for the production printing market.

The challenge

- Konica was looking for an AMR solution to achieve higher accuracy of materials handling in its warehouse and replace its magnetic stripe AGVs which offer little flexibility, are subject to low operating efficiency, and lead to high maintenance costs.

- Production line consists of more than 30,000 different materials, it is costly to manage the inventory and accuracy.

- High frequency of material delivery, low efficiency of manual material delivery, poor timeliness, and high labor-intensity.

Our solution

- 10 P800 robots in the warehouse and make use of Geek+ iWMS , for precise management of materials

- 3 M100 robots featuring SLAM navigation at the production line to deliver the materials from warehouse to production line

- Geek+ Moving System (GMS) receives task from iWMS and deliver the materials to production line automatically.

The Geek+ impact

- Improved inventory accuracy

- Stock-taking frequency reduced by 92%

- Material delivery efficiency increased by 31~42%

- Storage area saved by more than 32%

- Reduced labor intensity

Video

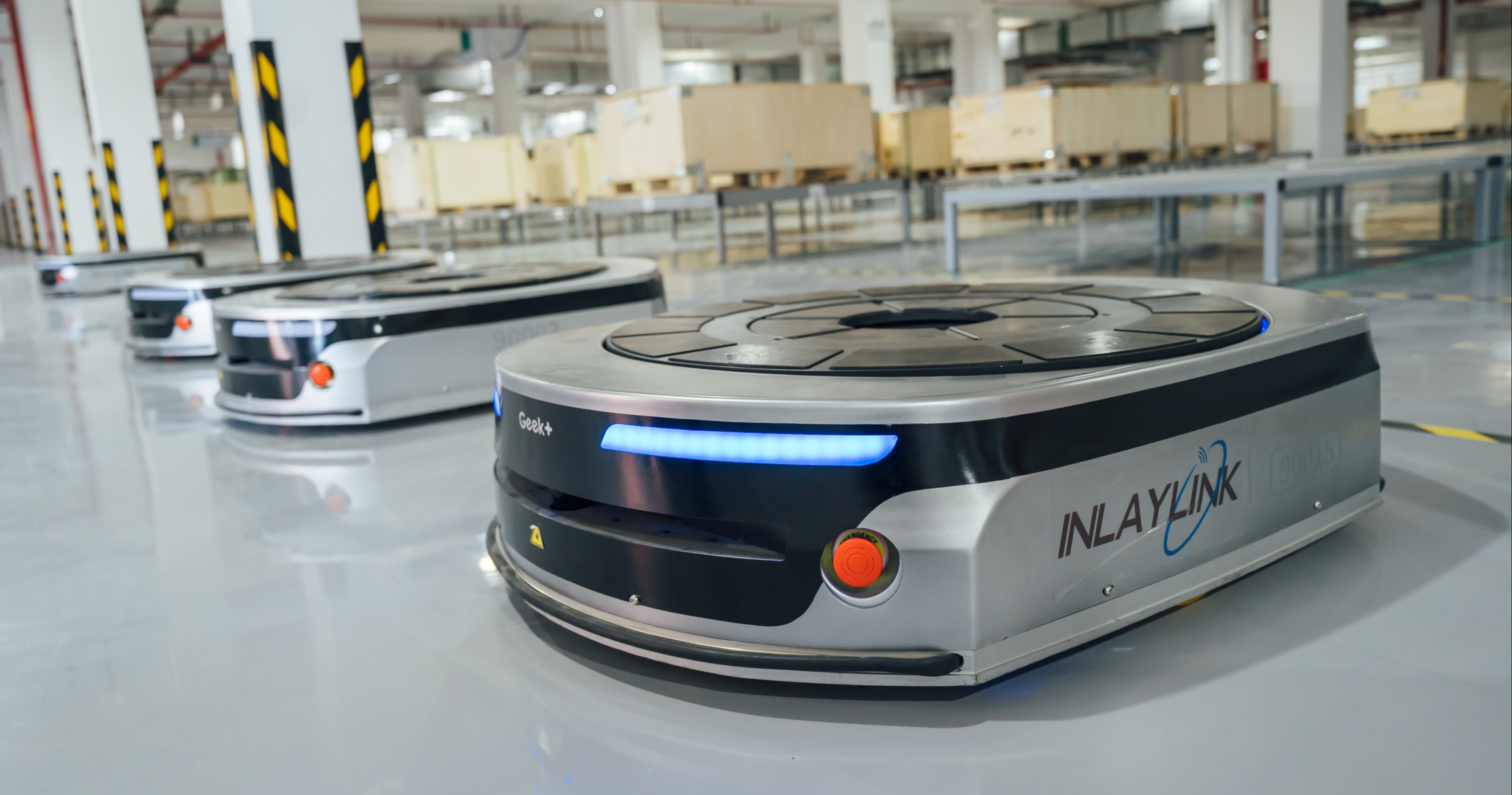

INLAYLINK factory realizes a smart upgrade with moving robots

The Customer

INLAYLINK is one of the world-renowned manufacturers of RFID tag antennas, specializing in the design, research and development, production, and sales of RFID tag antennas. It is also one of the few high-tech companies that can provide RFID data collection solutions and has won many world-known rewards.

The Challenge

- On-site materials are moved across floors and multiple areas frequently, and manual handling cannot guarantee the timeliness

- Manual handling is labor-intensive

- The value of a single material on-site is high. Checking, verification, signing, and handover are required for the delivery, online, offline, and warehousing links.

- The efficiency is low and the management cost is high.

- An information system is required to connect the warehouse and the production line to achieve physical and automatic docking of accounts.

Our Solution

- The site is equipped with 12 M1000 robots that transfers the materials out of the warehouse and sends them to the production lines.

- The robots are connected with vertical warehouse stackers, elevators, access control, and other systems to realize automatic, accurate, and timely distribution of materials across floors and sectors.

- The Geek+ Moving System (GMS) is connected to WMS and MES, enabling real-time visibility of the manufacturing process.

The Geek+ impact

- The integration information allowed a reduction in material management costs by 60%

- Material handling efficiency increased by 30%

- Reduced labor-insensitive operations

Video

Geek+ implements first large-scale AMR sorting system for Banggood’s e-commerce business

The customer

Banggood is a global e-commerce player focused on B2C cross-border export. With 37 international warehouses and deliveries bound for over 200 countries, Banggood is committed to bringing high-quality goods, efficient supply chain and top-class customer service to the world.

The challenge

Due to the accelerated shift towards e-commerce, Banggood faced challenges of rapid growth in online sales, unpredictable demand, labor shortages, and higher requirements for safer operations. With labor-intense processes often subject to inaccurate sorting, the company turned to Geek+ to automate its warehouse and realize and upgrade in its sorting operations.

Our solution

- To meet customer demand, Banggood turned to Geek+ Fleetsort solution, using a combination of S20T and P500 robots and realize more efficient and accurate operations through automated parcel sorting.

The Geek+ impact

- Reduced labor costs

- Reduced investment in fixed facilities

- Significant improvements in sorting efficiency

- 99% sorting accuracy

Geek+ & eStore Logistics partner to implement the largest rollout of AMRs in Australian e-commerce

The customer

eStore Logistics is Australia’s largest 3PL e-commerce fulfillment business. With a network of warehouses in Melbourne and Sydney, eStore strives to enable retailers across Australia to meet higher customer expectations by providing them with accurate, fast, and cost-efficient deliveries.

The challenge

Serving over 50 of Australia’s leading online retailers, eStore Logistics has a very wide SKU range. In turn, eStore Logistics was looking for a technology partner that could support its multi-customer business, flexibly meet rapidly changing SKUs and enable retailers to improve fulfillment performance while remaining profitable.

Our solution

-

On the company’s 26,000 sqm warehouse Geek+ deployed 200 picking robots.

The Geek+ impact

- 30% reduction in logistics costs for eStore’s customers

- Improved same-day delivery service

- Productivity increased by 300%

- 99 % Picking Accuracy

DSV doubled its productivity by deploying Geek+ picking system

The customer

DSV is a global supplier of transport and logistics solutions. With offices and facilities in more than 90 countries on six continents, DSV provides and runs supply chain solutions for thousands of companies on a daily basis.

The challenge

In its Hong Kong warehouse, they have more than 6,000 SKUs of tiny cosmetic items in a 45,000 sq.ft area. Workers take time to walk through the warehouse and spot the right item to fulfill each order. This lowers the picking productivity & accuracy.

Our solution

- Geek+ deployed 42 picking robots, 739 racks & 9 workstations in DSV warehouse. Once DSV received clients' order, Geek+ RMS would control the picking robots to bring the right rack with the right amount of items for workers to fulfill multi-order picking. Workers no longer need to walk through the warehouse.

The Geek+ impact

- Productivity has been doubled

- Improved picking accuracy

- Reduce in labor cost

- Overall 200% increase in bin location and thus increasing storage capacity

- Innovative product application, assist brand marketing effectively

Decathlon Triples Efficiency with Logistics Robots

About Customer

Founded in France in 1976, Decathlon is a professional sports goods retailer specializing in the mass sports market, integrating the entire production chain of sports product design, R&D, production, branding, logistics, and retail. With over 1500 stores in 49 countries, it is the largest sporting goods retailer in the world.

The challenge

The rapid growth of Decathlon's e-commerce business highlighted the limited performance of manual processes. Additionally, as a pioneer of the RFID technology, Decathlon required higher picking efficiency and accuracy to meet its business goals.

Our Solution

- Geek+ provides innovative warehousing solutions for Decathlon’s massive Kunshan warehouse: an RFID technology-based goods-to-person picking and inventory program

- The project area is about 2,000 square meters, with 46 P800 robots, 7 picking stations, and 7 single-point stations. The total inventory of the warehouse is nearly 300,000, involving more than 20,000 SKUs

The Geek+ impact

- Shipment capacity increased to 40,000 pieces/day

- Picking efficiency has reached 300 pieces/hour, 300% increased from manual picking

- Picking system integrated with RFID technology improve inventory management and increase accuracy

- The single-point station adopted to save space and make the operation more flexible

.png)

.png)

.png)