Featured Case Studies

Case Studies

.png?width=80&height=80&name=Manufacturing_0008_BMW%20(1).png)

Geek+ and Dr.Max Streamline E-Commerce Operations with Robotics

The Customer

Dr.Max is a leading pharmaceutical retailer in Romania and Central Europe, managing an extensive portfolio of products ranging from over-the-counter (OTC) medicines to cosmetics and dietary supplements. Its e-commerce operations serve a growing customer base, consistently ranking among Romania’s top 10 websites in terms of unique visitors. With its commitment to quality and innovation, Dr.Max sought to elevate its logistics capabilities to meet surging online demand while ensuring precision in delivering medical goods that directly impact patient well-being.

The Challenge

Dr.Max faced several critical challenges in scaling its e-commerce distribution operations:

- High Order Volume: Managing a diverse inventory of over 25,000 SKUs and processing them efficiently to meet customer expectations.

- Demanding Accuracy Requirements: Achieving near-perfect order fulfillment was vital in delivering essential medical supplies to patients.

- Growth Pressures: Rapidly growing online sales and seasonal peaks necessitated a flexible solution capable of scaling operations seamlessly.

- Waste Management: Minimizing product waste caused by expired inventory further complicated the logistical complexities.

Our Solution

To address these challenges, Geek+ introduced its cutting-edge goods-to-person AMR technology to Dr.Max’s Bucharest warehouse. The solution included:

- Deployment of Nearly 100 AMRs: These robots work tirelessly around the clock, retrieving items from storage and delivering them to picking stations with exceptional efficiency.

- Enhanced Picking System: Geek+ AMRs optimized batch processing, minimizing the need for special orders while considering key factors like expiration dates to reduce inventory waste.

- Scalable Operations: The modular AMR system allows Dr.Max to easily add robots to accommodate seasonal peaks and long-term business growth.

- Advanced Algorithms and Software: Integrated intelligence prioritizes order consolidation, ensuring faster fulfillment while maintaining order accuracy above 99%.

The Geekplus impact

The partnership with Geek+ delivered significant value to Dr.Max’s operations, including:

- Improved Efficiency: The AMRs operate 24/7, ensuring rapid and reliable order processing to keep up with customer demand.

- Enhanced Storage Utilization: Optimized handling of SKUs increased the warehouse’s capacity, accommodating more products without requiring additional space.

- Unmatched Accuracy: Over 99% fulfillment accuracy reduced errors, ensuring timely and precise deliveries to patients.

- Scalability and Flexibility: The ability to expand the AMR fleet provided future-proofing against demand fluctuations.

- Sustainability Improvements: Efficient inventory management reduced product waste, supporting environmental goals.

“Geek+ technology has provided us with a clearer view of our processes and allowed us to meet our patients’ needs more effectively than ever before. Their solutions are a vital part of our logistics strategy as we continue to grow.”

Sorin David, Supply Chain Director, A&D Pharma - Dr.Max Group

Video

S&S Activewear: Revolutionizing Apparel Warehousing with the PopPick Solution

The Customer

Founded in 1988 and headquartered in Bolingbrook, Illinois, S&S Activewear is a technology-driven distributor of apparel and accessories, serving the United States and Canada. With a product portfolio spanning over 80 brands, including Adidas and American Apparel, S&S caters to a diverse customer base, including retail brands, e-commerce companies, apparel decorators, promotional product distributors, entertainment merchandise dealers, lifestyle brands, and online custom apparel platforms. The company operates over 4 million square feet of warehouse space across North America, ensuring efficient distribution and delivery.

The Challenge

S&S faced several operational challenges as they scaled their business:

- Optimizing Employee Productivity: Ensuring efficient use of labor resources in a large-scale warehouse environment.

- Improving Order Quality: Maintaining high accuracy in order fulfillment to meet customer expectations.

- Enhancing Delivery Efficiency: Reducing lead times to ensure timely deliveries.

- Addressing Rapid Business Growth: Scaling operations to handle increasing order volumes and customer demands.

Our Solution

To address these challenges, S&S implemented Geek+’s PopPick Goods-to-Person solution. Key features of the solution included:

- Deployment of 340 AMR Robots: These robots automated the movement of goods within the warehouse, reducing manual labor and increasing efficiency.

- 24 PopPick Workstations: These workstations streamlined the picking process, enabling faster and more accurate order fulfillment.

- 2 Inbound/Outbound Workstations: Automated systems for seamless integration with conveyor lines, optimizing inbound and outbound operations.

The Geekplus impact

The implementation of the PopPick solution delivered significant value to S&S’s operations:

- Enhanced Picking Efficiency and Accuracy: The automated system significantly improved the speed and precision of order picking.

- Increased Processing Capacity: The warehouse now processes up to 4,500 order lines per hour, meeting high customer demand.

- Optimized Delivery Speed: Faster order processing and seamless integration with conveyor systems reduced lead times.

- Scalable Operations: The solution provided the flexibility to handle future growth and increased order volumes.

Video

Soccer.com and Geek+: Transforming Sports Retail Logistics with Robotics Innovation

The Customer

Soccer.com is a leading online retailer specializing in soccer gear, apparel, and equipment. Catering to players, coaches, and fans, the platform offers a wide range of products, including jerseys, cleats, balls, and training accessories from top global brands. Known for its commitment to the soccer community, Soccer.com also provides customization services, exclusive team gear, and resources to support players at all levels.

Video

Shop LC and Geek+: Transforming E-Commerce Logistics with Smart Automation Solutions

The Customer

Shop LC is a prominent home shopping network and online retailer offering a wide range of affordable luxury products, including jewelry, fashion, beauty, home goods, and lifestyle items. Known for its unique "Low Cost" approach, Shop LC provides exceptional value to customers while supporting sustainability and charitable initiatives through its "Your Purchase Feeds" program, which helps fight hunger globally.

Video

Transforming SP Digital’s Supply Chain with Geek+ and Boreal Automation

The Customer

SP Digital, a leading e-commerce company based in Chile, faced significant challenges managing massive spikes in demand brought on by the COVID-19 pandemic. To tackle these issues, SP Digital partnered with Geek+ and Boreal to implement an advanced robotics solution tailored to optimize their supply chain.

The Challenge

The COVID-19 pandemic drove a surge in online shopping, leaving SP Digital struggling to manage unprecedented demand for computer hardware and gaming products. Their existing supply chain faced inefficiencies in picking processes and warehouse throughput, making it difficult to keep up with the rapid changes in order volumes. To maintain customer satisfaction and sustain business growth, SP Digital sought a robust, efficient, and scalable solution.

Our Solution

Geek+ collaborated with Boreal to deliver a dynamic robotics solution that addressed SP Digital’s challenges. Key components of the implementation included:

- AI-Driven AMRs Geek+ integrated intelligent autonomous mobile robots to automate and optimize the picking processes within SP Digital's warehouses.

- Advanced Picking Robotics Boreal supported the deployment of advanced picking systems, tailored to handle SP Digital’s specific needs.

- Seamless Collaboration Geek+ and Boreal worked closely to ensure a smooth implementation process, minimizing disruptions while maximizing the operational impact.

This combination of smart robotics and collaborative integration resulted in a scalable, efficient, and data-driven warehouse solution.

The Geekplus impact

The deployment of Geek+ AMRs, combined with Boreal's expertise, delivered measurable outcomes:

- Optimized Warehouse Operations Streamlined processes enabled SP Digital to handle rapid shifts in order volumes while maintaining operational stability.

- Maximum Picking Efficiency Robotic automation improved picking speeds, significantly reducing turnaround times and enhancing overall throughput.

- Scalability During Peak Seasons The solution empowered SP Digital to meet massive spikes in demand without compromising accuracy or delivery timelines.

"For us, implementing Geek+ robotics systems in our value chain is an important step towards enriching and strengthening the services we offer our clients. We are very satisfied with the work done together with Boreal and Geek+. The transformation has been remarkable, and we look forward to further collaboration."

Diego Santander, CEO, SP Digital

Video

Rollship and Geek+ Transform E-Commerce Order Fulfillment in Hong Kong

The Customer

Rollship, backed by Chun Sing, has over 20 years of experience managing logistics for the e-commerce sector. Known for its customer-first approach, Rollship specializes in addressing the unique complexities of online retail. Seeking to enhance their operational capabilities, Rollship collaborated with Geek+ to revolutionize their order fulfillment processes in Hong Kong.

The Challenge

- E-Commerce Industry Pressure: Rising demand for faster and more accurate order fulfillment necessitated smarter operations.

- High-Volume Order Management: Handling an increasing number of SKUs demanded a solution to sustain capacity without compromising speed.

- Limited Integration: The need for seamless integration with existing warehouse management systems (WMS) and enterprise resource planning (ERP) platforms.

- Scalability and Seasonal Fluctuations: A logistics partner capable of adapting to changing order volumes and seasonal surges.

Our Solution

Geek+ implemented a range of advanced solutions to address Rollship's challenges:

- PopPick Goods-to-Person Solution: Mobile robotics paired with moveable shelves to enhance picking efficiency, enabling quick fulfillment of orders.

- Four-Way Shuttle System: A high-density storage solution for managing an extensive SKU variety while maximizing warehouse capacity.

- RoboShuttle Tote-to-Person System: Optimized vertical storage and retrieval capabilities, improving throughput and accuracy.

- Seamless Integration: Geek+ software integrated with WMS, ERP, and MES systems, ensuring efficiency without overhauling existing infrastructure.

- Scalability and Flexibility: Systems designed to handle fluctuations in demand, with quick adaptability to seasonal peaks like holidays or major campaigns.

The Geekplus impact

The collaboration resulted in substantial value for Rollship:

- Enhanced Fulfillment Accuracy: Advanced robotics reduced picking errors, ensuring higher customer satisfaction.

- Optimized Space Utilization: High-density storage improved facility use, accommodating more inventory efficiently.

- Significant Efficiency Gain: Automation streamlined operations, boosting order processing speeds and reducing bottlenecks.

- Adaptability for Growth: The scalable system allowed Rollship to confidently expand its operations in line with market demand.

- Integration with Existing Operations: A smooth transition with compatible systems preserved business continuity during

Video

Maersk Revolutionizes Supply Chain Operations with AGV Technology in HK

The Customer

- Maersk is a global leader in logistics and supply chain solutions, renowned for its commitment to excellence, innovation, and sustainability. With a network spanning over 130 countries, Maersk ensures seamless shipping and warehousing operations for millions of businesses globally.

- As part of its strategic focus on innovation, Maersk leverages cutting-edge technology to optimize supply chain operations and meet evolving customer needs.

The Challenge

- Inefficiencies in manual processes: Traditional pick-and-pack operations were time-consuming and resource-intensive, particularly during high-demand periods.

- The need for accuracy: Ensuring error-free order fulfillment was critical to maintaining customer satisfaction.

- Workforce strain during peak seasons: Seasonal spikes in demand placed significant pressure on manpower resources.

Our Solution

- Enhanced speed and accuracy: The AGV system executed picking tasks faster than traditional methods while achieving 100% accuracy.

- Labor optimization: By automating repetitive and labor-intensive tasks, AGVs significantly reduced dependence on manual labor, especially during peak demand periods.

- Improved efficiency: The combination of automated parcel handling equipment and scanning technology streamlined the end-to-end process, creating a simplified and reliable system.

The Geekplus impact

- Faster operations: The AGV system completed tasks at a speed significantly higher than manual pick-and-pack processes.

- Error-free fulfillment: The automation achieved 100% picking accuracy, eliminating errors and enhancing customer satisfaction.

- Manpower savings: During peak periods, the AGVs reduced the need for additional labor, ensuring smooth operations without added costs.

- Scalability for growth: By introducing automation, Maersk empowered its distribution center to handle increased demand while setting the stage for broader innovation initiatives.

“With the increasing use of the new technology in our warehouse, we enter in a new era with a lot of potentials to optimize our operations. Comparing with the menu, pick and pack, the AGB enables us to perform the activities in the warehouse a lot better. ”

Caroline Wu, Managing Director, Greater China, Maersk

Geek+ and BMW Brilliance : Advancing Automotive Manufacturing through Smart Logistics Collaboration

The Customer

BMW Brilliance Automotive Ltd., established in May 2003, is a joint venture between BMW Group and Brilliance Automotive Group Holdings. The company handles research and development, purchasing, production, sales, and after-sales services for BMW-brand automobiles in China. Brilliance BMW focuses on high-quality development and sustainability, aiming to become a provider of premium personal mobility services while driving sustainable practices across China's automotive value chain.

The Challenge

-

Increasing complexity and variety of automotive components (SKUs)

-

Difficulties in inventory management for small and medium-sized parts

-

Need for efficient, secure, and stable picking processes

-

Complex logistics environment requiring advanced, high-performance solutions

Our Solution

To address these challenges, BMW Brilliance implemented Geek+'s standard "goods-to-person" picking solution, an AI-driven system designed to optimize logistics operations and improve overall efficiency.

- P800R Picking Robots : These robots were deployed to optimize the picking process in the general assembly workshop, specifically for F-koli (small parts) logistics areas.

- Advanced Software Integration : Seamless integration with BMW Brilliance’s warehouse management system enabled real-time inventory tracking, precise order fulfillment, and data-driven decision-making.

- Comprehensive Staff Training : Geek+ provided thorough training programs to ensure that staff could safely and efficiently operate the new automated systems.

- Scalability and Flexibility : The solution was designed to be scalable, allowing BMW to expand or adapt the system as production volumes or SKU complexity grows.

The Geekplus impact

The implementation of Geek+'s innovative logistics solution delivered impressive results for BMW:

- 400% Increase in Picking Efficiency : Streamlined operations drastically improved productivity and minimized internal workflows' bottlenecks.

- 64% Reduction in Labor Costs : Automation reduced manual tasks, freeing up human resources for higher-value activities.

- 99.99% Picking Accuracy : With the help of AI and robotics, nearly error-free picking processes were achieved, boosting inventory reliability.

- Energy Optimization : A significant reduction in overall energy consumption contributed to Brilliance BMW's sustainability goals.

- System-Wide Integration : The digitalized solution ensured full connectivity and synchronization across all logistics links, enhancing operational transparency and control.

“This project is an important step in BMW Brilliance’s move towards smart manufacturing and digital factories, and a key milestone in our logistics transformation! I like to call it ‘collaborative innovation.’ We worked closely with Geek+ to develop an efficient and flexible smart logistics solution, which not only realized the integration and coherence of the warehouse management system, but also provided us with more flexible and faster solutions for future upgrades and renovations, setting a model of a people-oriented sustainable green factory for the industry.”

Ralf Schieder, Vice President of BMW Brilliance Automotive Strategy and Logistics

Video

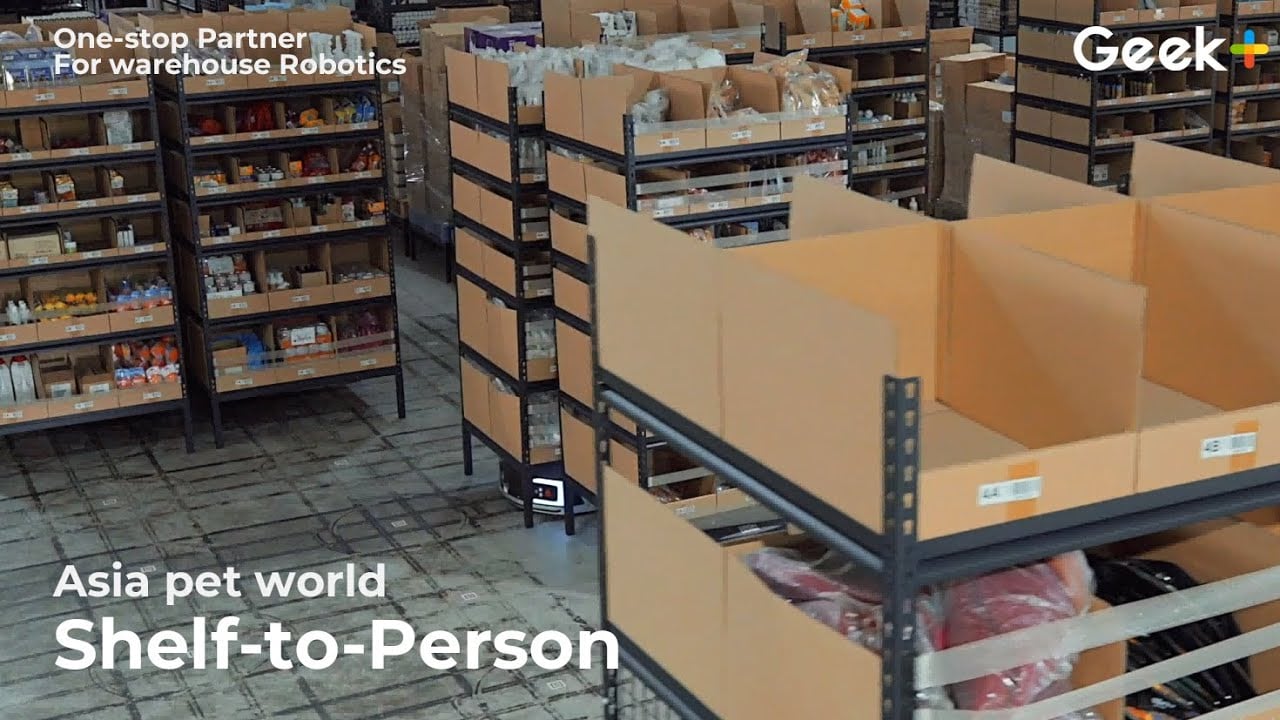

Asia PetWorld and Geek+ Collaborate to Revolutionize Warehousing in the Pet Supply Industry

The Customer

- Asia PetWorld, a global leader in pet supply distribution, handles 8,000 unique SKUs daily.

- Supplies a wide range of pet products, including large pet beds, cat litter, and bulk dog food.

- Operates in a labor-intensive and complex warehousing landscape with high product diversity.

The Challenge

- High SKU volume: Managing a vast assortment of 8,000 SKUs demanded significant labor and resources.

- Rising labor costs: Increasing operational expenses due to dependency on manual labor.

- Handling heavy, bulky items: Products such as large pet beds and bulk pet food added physical strain on workers.

- Labor shortages: Difficulties in maintaining efficient operations due to workforce shortages.

Our Solution

- Robots capable of efficiently handling bulky and heavy items, such as large pet beds, cat litter, and dog food.

- Improved inventory management through intelligent automation, enabling operational flexibility.

- Enhanced employee ergonomics by reducing the physical strain of manual tasks, fostering a safer and healthier work environment.

The Geekplus impact

- Efficient operations: A 99.5% picking accuracy leading to more reliable order fulfillment.

- Employee well-being: Reduced physical strain and created a safer, more comfortable work environment for workers.

- Rapid transformation: Warehouse operations were revolutionized within just two months.

- Scalable solution: The robotics system ensured flexibility for future growth and changes.

- Customer satisfaction: Enhanced inventory management improved overall customer service experience.

“In Singapore, the labor availability is always a challenge for warehouse owners. The situation is even worse for the pet industry where workers often need to manage heavy, awkward items. After adopting the Geek+ robots, we are better able to handle our stocks and can offer a more comfortable workplace to our employees.”

Sebastian Wiradharma, Director, Asia PetWorld

Video

Geek+ Implements Japan's Largest Shelf-to-Person PopPick System for ASKUL

The Customer

ASKUL is a leading Japanese company offering a wide range of products and services to businesses. Established in 1993, ASKUL has cemented its reputation as one of Japan’s primary suppliers of office supplies and equipment. With a dedication to operational excellence, ASKUL has consistently embraced innovative technologies to improve its logistics network and provide exceptional customer experiences.

The Challenge

ASKUL faced significant operational hurdles as its product portfolio and customer base expanded over the years. The primary challenges included:

- Growing Inventory Needs: The company's diversified product line demanded storage solutions capable of handling higher volumes more efficiently.

- Limited Storage Space: ASKUL needed to maximize storage density to utilize its warehouse space effectively.

- Operational Scalability: Addressing increased demand required solutions that could handle higher order volumes without compromising speed or accuracy.

To meet its growth objectives while maintaining superior service standards, ASKUL turned to Geek+ for an innovative automation solution.

Our Solution

- Fleet of AMRs: Highly autonomous robots enhanced goods retrieval and inventory workflows, reducing reliance on manual labor.

- Smart Sorting System: Advanced sorting solutions integrated seamlessly to handle high-volume orders with unmatched accuracy.

- Vertical Space Optimization: Innovative racking systems maximized floor-to-ceiling storage, accommodating increasing inventory needs.

- Interactive Data Visualization: Real-time dashboards offered full visibility into operational performance and streamlined decision-making.

The Geekplus impact

Geek+ provided ASKUL with a cutting-edge Shelf-to-Person PopPick System tailored to the unique demands of their operation. Key features of the solution included:

- High-Storage-Density Logistics: The PopPick System incorporates picking robots that transport movable shelves from storage locations to PopPick workstations. The robotic arms at these stations present totes or boxes directly to operators, ensuring seamless item retrieval.

- Streamlined Warehousing Workflows: The system enables efficient picking processes, handling up to 500 lines per hour, significantly improving workflow automation.

- Scalable Robot Deployment: With over 318 robots integrated into the ASKUL Value Center, the robots work cohesively to optimize space utilization and throughput.

- Enhanced Customer Service: By implementing a logistics system characterized by speed, precision, and scalability, ASKUL improves order accuracy and delivery performance for its customers.

This solution not only meets current demands but also sets up ASKUL for sustainable growth, with room for further innovation and scaling.

“The Geek+ PopPick System is designed for high efficiency and can significantly improve the overall productivity of warehouse operations. This implementation will showcase to the market the next generation of warehouse automation, setting a new industry benchmark.”

Hirokazu Kato, President and CEO of Geek+ Japan

Video

Geek+ and CEVA Logistics Transform Footwear Fulfillment with AMR Technology

The Customer

CEVA Logistics is a global leader in logistics and supply chain solutions, supporting businesses across various industries with expertise in contract logistics and freight management. Operating in more than 170 countries, CEVA specializes in delivering scalable, innovative solutions to optimize supply chains and enhance operational efficiency. With a strong focus on driving value through technology, CEVA is a trusted partner for iconic brands in the footwear and apparel sector, providing fulfillment, distribution, and last-mile delivery services.The Challenge

- High order complexity: Managing daily volumes exceeding 10,000 outbound items while fulfilling both wholesale and retail orders.

- Accuracy demands: Ensuring precise inventory handling and order fulfillment to meet customer expectations.

- Ergonomic issues: Alleviating the physical strain of manual tasks for warehouse staff.

- Scalability needs: Developing a flexible solution to handle increasing demand and operational complexity.

Our Solution

- High-capacity robotics: P-800 robots with a 1,000-kilogram payload work seamlessly across inbound and outbound operations.

- Enhanced speed and precision: Robots operate at a maximum speed of 2 m/s, ensuring rapid and accurate item movement.

- Optimized workflows: Intelligent algorithms improve inventory placement, reducing delays and maximizing efficiency.

- Improved ergonomics: Robots handle heavy lifting, creating a safer and more comfortable workspace for employees.

- Quick implementation: The system was fully operational in record time and integrated with existing workflows.

- ostering a safer and healthier work environment.

The Geekplus impact

- Operational excellence: Over 15 million units processed annually with accuracy and efficiency.

- Improved scalability: The flexible solution accommodates fluctuating demands with ease.

- Employee well-being: Safer conditions and reduced physical strain for warehouse staff.

- Energy efficiency: The ability to operate in low-light conditions reduced energy consumption significantly.

At CEVA, we define innovation as the implementation of new ideas with business impact. As a result, we are always looking for the best solutions for our clients, scanning the technology horizon alongside our partners. The Geek+ solution is a great fit for our operation in Grobbendonk, providing a more comfortable working environment for on-site employees, while at the same time handling a far greater order volume

Bart Beeks, Global Head of Contract Logistics at CEVA Logistics

Video

Geek+ and DFI Retail Group Revolutionize Warehousing for Wellcome Supermarket

The Customer

DFI Retail Group is a leading retail enterprise in the Asia-Pacific region. Known for its commitment to quality and value, DFI operates numerous renowned brands offering top-tier retail experiences. Among them, Wellcome Supermarket stands out as one of the largest supermarket chains in Hong Kong, catering to millions of consumers with a wide range of products and services.

The Challenge

- Handling diverse inventory types: The warehouse needed to accommodate a mix of palletized storage and single-item picking, making efficient operations more complex.

- Minimizing manual errors: The traditional processes were prone to human errors, which could impact product availability and customer satisfaction.

- Space optimization: Maximizing storage space from floor to ceiling was critical to handle the growing inventory in a limited area.

Our Solution

- Pallet-to-Person Technology: This innovative system allows robots to bring pallets directly to station operators, making the pick-and-pack process faster and more reliable.

- Robots for Smart Operations: Over 30 Geek+ picking robots and four-way shuttles were deployed, revolutionizing inventory handling and movement.

- Space Utilization Optimization: By leveraging vertical storage capabilities, the solution maximized the use of floor-to-ceiling warehouse space.

The Geekplus impact

The implementation of Geek+ technology transformed Wellcome’s warehousing operations, delivering significant results:

- Enhanced efficiency: Operational efficiency increased by 2X, as robots streamlined picking and storage processes.

- Error reduction: The automation significantly minimized human errors, enhancing inventory accuracy and order fulfillment reliability.

- Space maximization: The intelligent design enabled the warehouse to fully utilize space, accommodating diverse inventory needs effectively.

- Safety improvements: Automation reduced the risks associated with manual labor, creating a safer workplace environment.

- Cost savings: By automating core processes, Wellcome achieved long-term cost reductions and operational sustainability.

“We collaborated with Geek+ to establish the first Automated Smart Warehouse for Wellcome. Not only does it improve efficiency but it also saves us a substantial amount of space and cost.”

Michael Haas, Supply Chain Director of DFI Retail Group

Video

.jpg)

.jpg)

.png?width=200&height=142&name=images%20(2).png)