Geek+ Helps China Reach Net Zero Carbon Emissions Goal by 2060

As the world continues to vigorously scale up its green energy commitment, Geek+ is empowering energy companies with its products. China, the world’s largest energy consumer, made a bold statement last year and announced to the United Nations and the world that it would it would become carbon neutral by 2060.

Want to Listen to this article on the go? Click Here.

TICA Systems, a Chinese energy company, has opened a new door to green energy in China. TICA has expanded in six major energy markets, including geothermal power generation, industrial waste heat power generation, LNG cold energy power generation, biomass energy, solar thermal power and industrial energy storage.

Geek+ is working in TICA warehouses to create smart logistic solutions across the country. The Sky-Storage & Ground-Pick four-way shuttle solution was Geek+'s choice for the company. The project only took two months to rapidly deploy. The project has been running smoothly for more than half a year, and will continue to achieve both high storage density and operational efficiency for TICA.

The wave of intelligent automation is coming.

How can the manufacturing industry seize the opportunity?

In order to produce efficiently, TICA must ensure that the parts in their raw material warehouse are matched and distributed to the line side on-demand. However, the traditional manual search for parts made employees walk between the warehouse and the production line and was error prone.

One stop Sky-storage& Ground-picking

TICA leads the multi-level storage and picking solution

In order to ensure the smooth operation of the warehouse and meet the high tact demand of the production line, TICA introduced the Geek+ Sky-Storage & Ground-Pick solution with high-density multi-level storage and picking.

The four-way vehicle and AMR robot work together to perfectly combine intensive storage and efficient picking into one

TICA and Geek+ set up automated warehouses and AMR areas in the assembly area near the production line. Several X1200 four-way shuttles are equipped with intelligent high-speed elevators for multi-level storage, which greatly improves the utilization of three-dimensional space; Geek+ AMR robots are connected on the first floor with four-way shuttle to transfer the goods out of the warehouse, and carry out the picking and distribution on-line operations, integrating intensive storage and efficient picking.

Ultra-high density storage

Save every inch of storage capacity

The height of the Geek+ X1200 four-way shuttle is 55mm (2.1 inches) lower than the industry average, and the volume is 10% less. Compared with traditional forklifts, it can save 60% of the aisle space. Through the narrower aisle and higher depth, the three-dimensional storage space from the ground to the ceiling is fully utilized, and the storage space is greatly improved.

Automated and efficient production

Accurately meet diverse needs

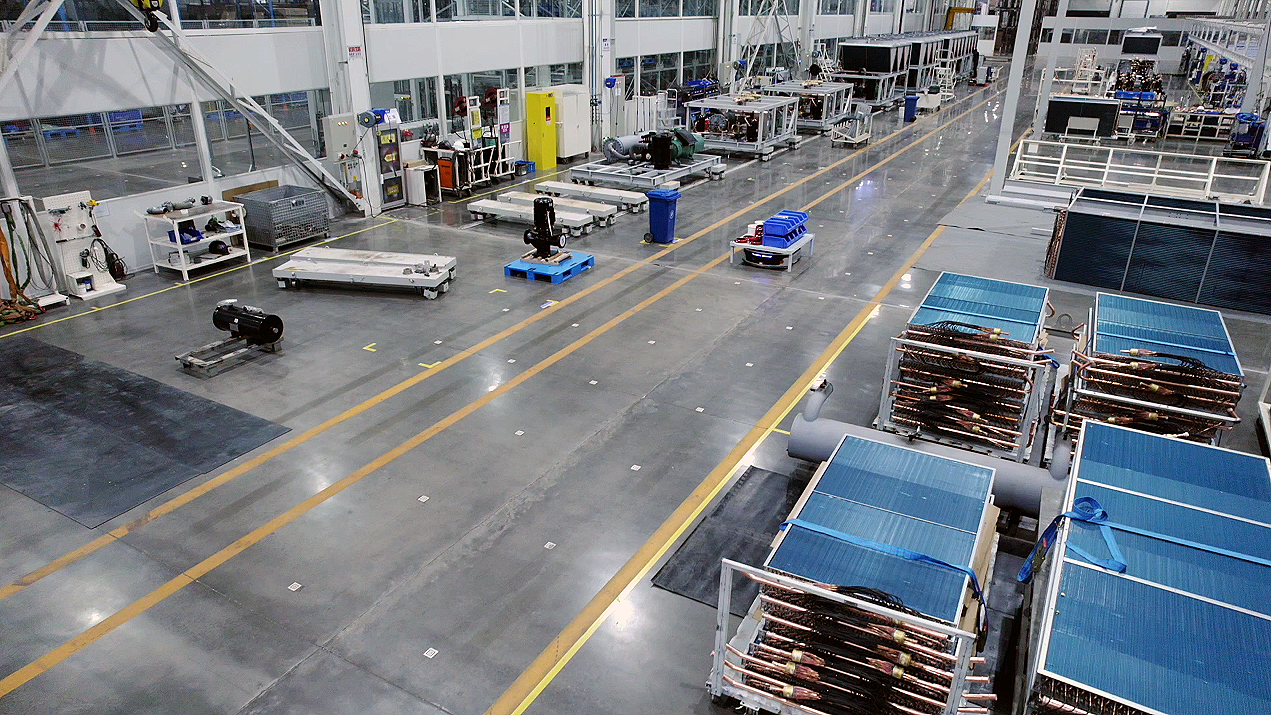

In Geek+'s Sky-Storage & Ground-Pick solution, the four-way shuttle automatically transfer pallets to the picking point, and cooperates with the goods-to-person system for efficient picking, which greatly reduces the ineffective walking of personnel. The solution utilizes automatic handling from the storage area to the point of use, and connects smoothly with the upstream system to meet the management needs of on-site material handling and lean production. Exterior view of TICA Systems

Exterior view of TICA Systems

Precise positioning and safe obstacle avoidance

Flexible response to human-machine coexistence

The Geek+ four-way shuttle adopts the industry's advanced safety obstacle avoidance technology, and the 2-meter (6.56 ft) obstacle avoidance stopping distance is 20% shorter than the industry average. The AMR adopts flexible laser SLAM + QR code hybrid navigation to ensure accurate positioning within the TICA raw material warehouse.

With constant innovation, Geek+ effectively solves the pain points and difficulties for customers while delivering high-quality projects. Geek+ and TICA are working together to create a milestone in green energy smart logistics.