It's high time for 3PL to digitalize the supply chain

The worsening COVID-19 outbreak has thrown the entire world into disarray, including the global supply chain. As traditional distribution and supply chain networks come to a grinding halt, how will third-party logistics (3PL) companies be impacted?

Short-term bump due to consumer demand growth

At present, 3PL companies are seeing a soaring demand amidst coronavirus lockdown. Following social distancing measures and countrywide lockdowns, the shift from offline to online has accelerated. In Feb 2020, HKTVmall, one of the largest e-commerce companies in Hong Kong, recorded a 169.3% increase in Gross Merchandise Volume (GMV) and a 165% increase in average daily order, a substantial increase compared to the same period the previous year. The result of this influx in order volumes is the surge of business for 3PL companies, which has gone up by 2-3 times since lockdowns were implemented. Moreover, since the scale of “home delivery” has grown rapidly, many retailers have turned to 3PL companies to resolve the bottleneck in overall logistics and distribution capacity.

Long-term (demand) slump due to economic drop-off

However, experts predict that the leap in consumer demand and business for global 3PL companies is a temporary phenomenon. As the global economy gradually slows down and inventories balance out, a decline in global 3PL revenues is expected. Evan Armstrong, president of the 3PL market research and consulting firm Armstrong & Associates, claimed that the market for 3PL services will likely decline with around 10 per cent during the second quarter of 2020, compared to the first quarter. He projected that a “pretty hard” ripple effect will follow through the US manufacturing and supply chain as the virus spreads and more people fall sick. As a result, warehouses, fulfillment centers, and manufacturing centers are likely to be functioning under capacity, even if demand remains strong. In turn, operational disruptions, labor shortages, and a general slowdown in activity, will lead to a reduction in global 3PL business and revenue.

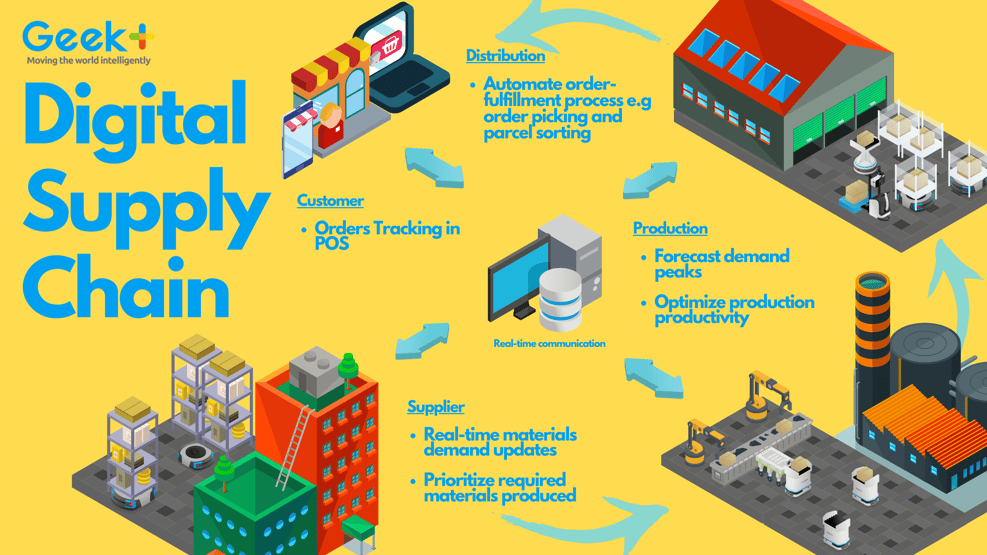

Digitalization of the supply chain

In light of labor shortages as well as rising manpower costs, it is crucial that 3PL companies consider digitalization of their supply chain, so that each segment and link of the supply chain can have full visibility into the needs and challenges of others. Through transparency and integration of supply and demand signals, companies can react to fluctuating demands and disruptions, and stay one step ahead in anticipating these changes. This would enhance the overall resilience and responsiveness of the supply chain network and mitigate the knock-on effects of black swan events like the coronavirus pandemic.

Hence, the big question is – how can companies achieve digitalization of their supply chains? It is imperative to introduce automation to warehouses, so as to improve the productivity and safeguard the stability of operations. Geek+ robotic solutions are very beneficial as they bring 2-4 times increase in productivity and 24/7 unmanned, flexible operations. Moreover, these robots can integrate with the digital supply chain with minimal operational disruptions and be the essential hardware.

For example, when low inventory levels are detected by the Warehouse Management System (WMS), orders to fill up the inventory will be automatically sent to the supplier. This order will then be received by the WMS of the supplier and a command will be sent to Geek+ Robot Management System (RMS). Geek+ robots can then begin order picking, resulting in an efficient and seamless process of order fulfillment. Aside from picking systems, sorting systems are also available to streamline parcel sortation and cross-docking.

How effective is warehouse automation?

NISSA Centre, a company specialized in professional digital turnkey printing, experienced the delight of warehouse automation after implementing a robotics sorting solution by Geek+ which led to a sorting rate of over 500 pieces per hour. An achievement that would have been impossible if the company had continued to rely on traditional manual operations. With 12 S20 robots, 22 drop-off stations and 2 workstations in place, the warehouses at NISSA Centre can operate more efficiently and with reduced labor costs.

Another company that benefited greatly from warehouse automation is DSV, a global 3PL company supplying transport and logistics solutions. In its Hong Kong warehouse, the company has more than 6,000 SKUs of tiny cosmetic items in a 45,000 sq. ft area where employees had to take time and spot the right item to fulfill each order. This has greatly hampered not only the picking efficiency, but the picking accuracy as well. To tackle this issue, DSV adopted 42 picking robots, 739 racks, and 9 workstations from Geek+. By adopting the automated picking system they were able to achieve improved picking accuracy, doubled productivity, reduced labor costs, and increased overall storage capacity by 200%.

DHL, a big player in the 3PL industry, also embraced warehouse automation in its warehouses in Japan. They partnered with Geek+ to launch a Robotic Mobile Shelving Warehouse, a picking system that effectively aided the company by reducing business risks, optimizing operational efficiency and improving service quality, whilst achieving seamless integration with the warehouse management system.

Moving forward, the future seems ambiguous as the COVID-19 situation evolves and consumer demands and business needs continue to fluctuate. The only sure-fire method for 3PL companies that can reduce the uncertainty, mitigate supply chain risks and ensure sustained operations and prosperity is undoubtedly to invest in warehouse automation.

If you want to learn more about the automation trend, download our white paper now:

About Geekplus

Geekplus is a global leader in mobile robotics technologies. We develop innovative robotics solutions for order fulfilment. More than 850 global industry leaders use our solutions to realize flexible, reliable, and highly efficient automation for warehouses and supply chain management.

Media Contact

Marie Peterson, VP International Marketing & Communications

Marie.peterson@geekplus.com