Distribution Center Order Fulfillment Solutions

Revolutionize Your Supply Chain with Advanced Automation Solutions

Our robotics solutions empower grocery retailers and distributors to handle high volumes of goods and multi-SKUs with ease.

Trusted by 770+ Global Customers

Space-Intensive Operations

Space Constraints

Limited facility space leads to overcrowding and inefficiencies, making it harder to streamline operations. |

High-touch Processes

Frequent touching and shuffling of pallets increase labor costs and risk of damage to goods. |

Inefficient Layout DesignPoor warehouse layouts can hamper workflows, causing unnecessary delays and congestion. |

Storage ChallengesManaging diverse inventory types in cramped storage areas often leads to misplacement and inaccuracies. |

Expansion Pressure

The push for greater throughput conflicts with existing space limitations, creating bottlenecks. |

Inventory OverflowSurging inventories, especially during peak periods, exacerbate spatial issues and disrupt operations. |

Purpose-Built Solutions for Unified Grocery Fulfillment

Shelf-to-Person System

Direct-to-picker inventory access for high-demand and fast-moving products.

✅ Perfect for managing diverse grocery assortments, from pantry staples to beverages

✅ Maximizes workflow efficiency with an organized inventory system

✅ Reduces order processing times for multi-unit fulfillment scenarios

✅ Automates shelf delivery for enhanced accuracy at scale

Tote-to-Person System

High-density storage for quick and seamless order fulfillment.

✅ Ideal for fast-turn goods like snacks, frozen foods, and dairy

✅ Double robot configuration accelerates picking and consolidation

✅ Handles seasonal stock surges and varied order requirements efficiently

✅ Optimized design for space-constrained facilities and urban hubs

Pallet-to-Person System

Large-scale movements for bulk goods across multiple temperature zones.

✅ Handles ambient, chilled, and frozen products with ease

✅ Streamlines pallet handling for regional and cross-dock operations

✅ Minimizes forklift dependency, increasing safety and precision

✅ Enhances efficiency in cold storage through automated transfers

.gif?width=600&height=342&name=640%20(3).gif)

Unified Software

Real-time intelligence to manage inventory and fulfillment processes.

✅ Automates batching, route optimization, and slotting for all SKUs

✅ Tracks performance across temperature-controlled and ambient zones

✅ Integrates seamlessly with WMS/ERP systems for data synchronization

✅ Provides business insights for effective demand and replenishment planning

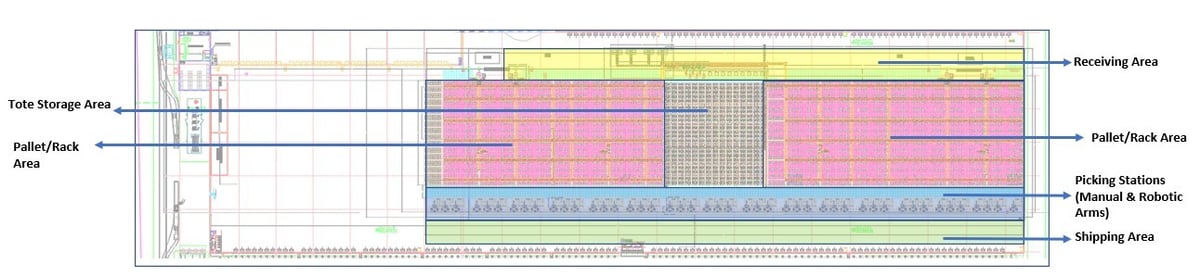

Sample Layout

A tailored automation setup designed for integrated grocery fulfillment operations.

✅ Unified Tote-to-Person and Pallet-to-Person workflows for high-volume centers

✅ Smart zoning for receiving, pallet storage, and outbound flows

✅ Consolidated robotic systems for wrapping and picking

✅ 3 shift operations with SKU interchange between Tote-to-person and Pallet-to-person areas based on SKU seasonality and demand

Measurable Improvements for Grocery DCs & Regional Retailers Operations

<300%Increased ThroughputProcess more orders with fewer resources, allowing you to handle volume spikes and growth without adding warehouse space. |

65% ↓Faster Order FulfillmentCut order processing times to meet tight delivery windows and ensure stores receive stock when they need it. |

40% ↓Lower Operational CostsReduce labor costs, minimize errors, and optimize space utilization for significant operational savings. |

99.9%Improved Inventory AccuracyNear-perfect inventory tracking reduces out-of-stocks and overstocks that impact store operations. |

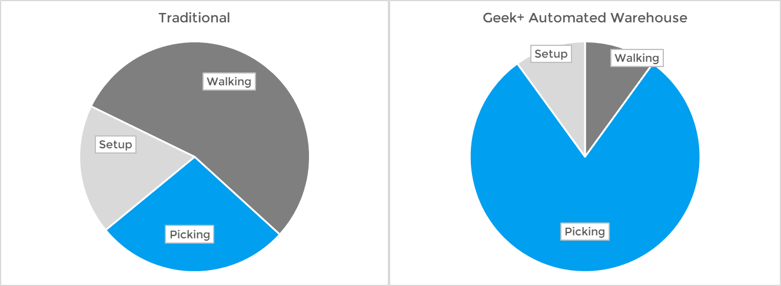

70% ↓Labor OptimizationReallocate staff from repetitive manual tasks to higher-value activities that enhance customer experience. |

4xEnhanced AdaptabilityQuickly adjust to changing demand patterns, new product introductions, and seasonal variations. |

Trusted by Leading Grocery DCs & Regional Retailers

ASDA

Sort up to 2000 parcels/hour

✅ Geekplus deployed 60 S20C sorting robots in ASDA's 3,875 sqft. cross-docking facility. Geekplus solutions provided ASDA the ability to flexibly respond to rapid changes in order volume to ensure better customer service during peak times.

✅ Increased operational flexibility by over 65% and sorting efficiency up to 2000 parcels/hour.

Lianhua Supermarket

2x storage capacity

✅ To meet rising demand across more than 5,000 grocery stores, Lianhua Supermarket integrated Geekplus Pallet-to-Person solutions in its smart warehouse distribution center, serving more than 90 urban locations.

✅ Optimized vertical space with multi-level pallet storage, and doubled storage capacity to handle 80,000 SKUs.

Haitian Grocery

Increased inbound throughput to 285 pallets/day

✅ Haitian Grocery automated distribution center operations and workflows by deploying Geekplus Pallet-to-Person solutions.

✅ Optimized storage capacity to 2,500 pallets with an inbound rate of 285 pallets/day.

I'm really proud to see Geekplus systems performing so well. They are delivering great results and hitting the key metrics.