Tote-to-Person mobile robot innovation revitalizes 3PL operation

In 2020, a major U.S. 3PL that provides solutions for cross-border e-commerce brought the Geekplus Shelf-to-Person solution to their distribution facility in the Midwest. The goal? Better serve overseas customers selling to the U.S. market by processing shipments faster.

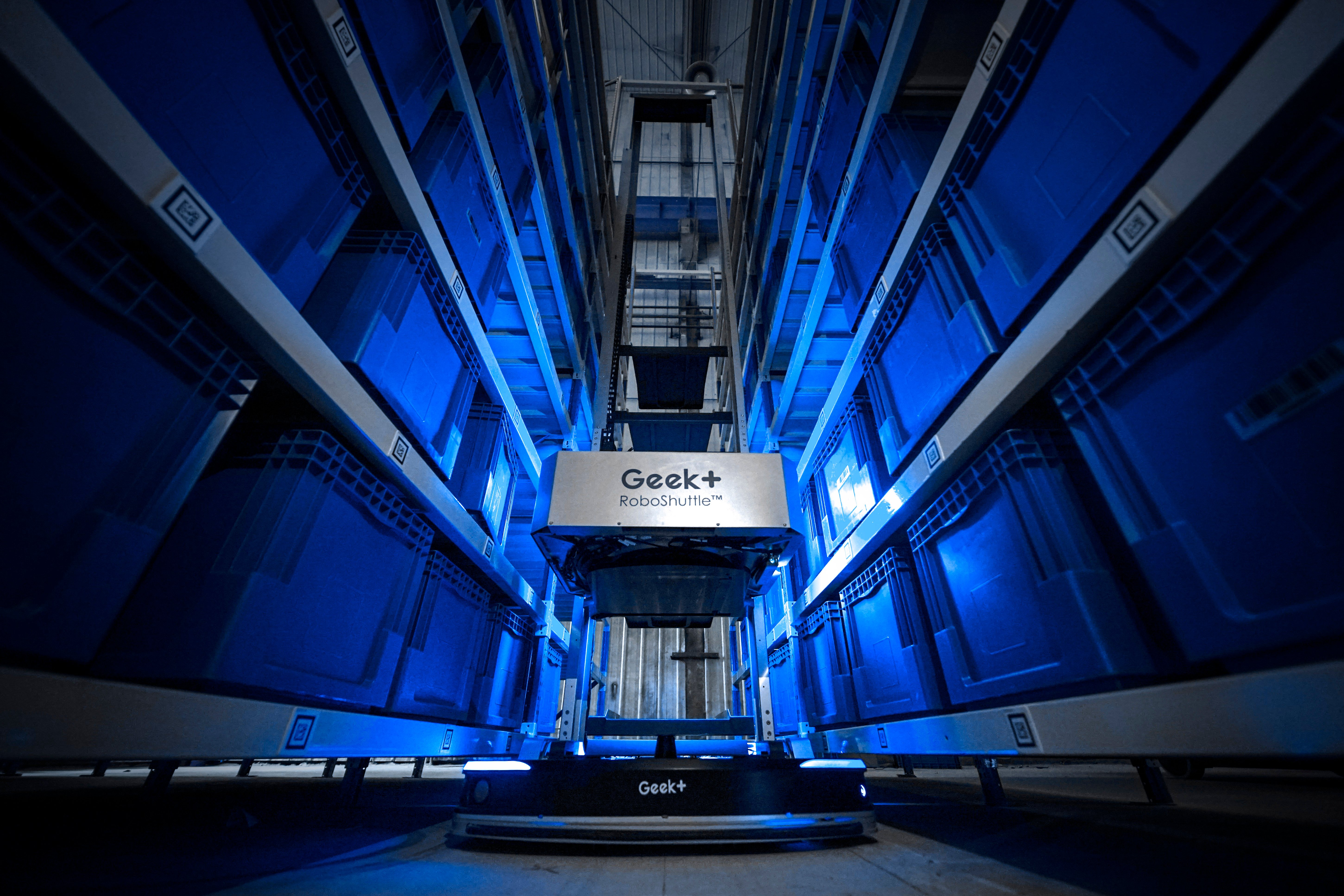

The Goods-to-Person flagship solution enabled them to increase order fulfillment efficiency without fixed infrastructure investments. As the company grew, it discovered the need for a storage solution that could be installed while the existing solution was still running. There was no sense in letting all that vertical warehouse space go to waste, so they added the 11-meter Geekplus Tote-to-Person innovation.

Geekplus will celebrate the official U.S. debut of its Tote-to-Person solution, the industry’s tallest mobile order fulfillment robot, at Booth C6076 during the Modex supply chain conference and Booth #6B61 during LogiMAT 2024.

All over North America, warehouse space is still at a premium. In this market, 3PLs, retailers and other warehouse operators face a common issue: how do they fully optimize limited storage space without negatively impacting order fulfillment picking efficiency?

3PLs face an additional operations issue. These logistics solutions providers always have multiple customers in the same facility, all with myriads SKUs. And each customer could have its own seasonal sales patterns and differing order fulfillment needs. To add to the puzzle, 3PLs are routinely adding new customers into the same facility. The Geekplus Tote-to-Person solution provides high flexibility and adaptability to fit this sometimes volatile and always shifting business model.

Book a live RoboShuttle System demo at Modex 2024

or

Book a live RoboShuttle System demo at LogiMAT 2024

In the Tote-to-Person solution, two robots work together: one that goes high to store totes, one that’s fast to deliver totes to picking stations. Together, it provides high-density storage for small- and medium-sized goods to maximize vertical warehouse storage without sacrificing fulfillment speed. As the customer soon found, the mobile robot solution can be integrated easily into additional Geekplus offerings.

The company soon found the myriad benefits of the Tote-to-Person solution:

✅Double deep storage: 5X increase in storage capacity when switching from manual picking

-

✅Narrow functionality: The robot operates on narrow aisles, adding 50% storage capacity compared to traditional storage methods

-

✅Picking flexibility: Handles totes and carton in a variety of sizes

✅High efficiency: Ergonomic picking stations lead to fast fulfillment; robots can deliver to pickers every 1.5 seconds

-

✅Quick training time: Picture-based and intuitive software means employees ramp up quickly

Warehouse employees also like the solution because picking a range of order types at the same workstation means less walking. The ergonomically designed workstation means faster and more comfortable picking.

It's all controlled by a multi-agent scheduling and task management platform system that supports both cloud and local deployment. The system oversees path planning, traffic management, task allocation, capacity optimization, safety emergency stops, and large-scale mobile robot cluster tasks in real-time. The software platform, which is intuitive and easy-to-use to reduce training time and aid worker retention, is powered by smart algorithms.

Visit Geekplus at Modex 2024 and Geekplus at LogiMAT 2024 to learn how the ultra-flexible large and small cart Tote-to-Person solution maximizes warehouse storage potential without sacrificing speed.

-png.png?width=500&name=Why%20Geek+%20(5)-png.png)