5 Questions to Ask when Choosing an AGV or AMR

Perhaps unknown to many, the first discovery of Automated Guided Vehicles (AGVs) actually happened in 1954, by Arthur Barrett. Since then, AGVs have advanced tremendously to revolutionize material handling and transport.

Table of Content:Types of AGV Navigation Systems

5 Questions to help you select the right AGV

Frequently Asked Question: AGV vs AMR

Types of AGVs

.png?width=1280&name=Questions%20to%20Ask%20AGV%20(2).png) Automated Guided Carts (AGCs) or Under Ride

Automated Guided Carts (AGCs) or Under Ride

AGCs are mobile platform robots that engage carts, trollies, or shelves underneath to transport them safely. This engagement is made using a lifting device or a pin hook, while the load remains above or on the AGC - for this reason, AGCs are often referred to as Under Rides. AGCs are the most affordable type of AGVs, ranging from around $15,000 (for a 1-ton payload) to $25,000 (with natural navigation).

Forklift AGVs

An automated pallet jack is a type of forklift AGV, conceived to transport palletized loads in manufacturing facilities. They can be employed in floor-to-floor operations and can typically fulfill lifting requirements up to 2 meters high. There are also automated forklift trucks that are more versatile in nature and can thus be configured to handle heavy payloads, up to 4 ton, or high stocking operations around 8 meters high. Other types of forklift AGVs include reaching trucks and Very Narrow Aisle (VNA) trucks, which are both designed to operate in narrow aisles while performing high lifting loading operations. The only difference between the two is that the former is smaller and faster compared to the latter.

Unit Load Vehicles

Unit Load AGVs are self-driving vehicles furnished with roll conveyors, that can navigate swiftly and safely in warehouses and production facilities. They are built to carry one or several unit loads at a time, to and from conveyors, stands, end-of-line equipment (e.g. robots, palletizers) as well as automated storage and retrieval systems (ASRS).

Towing AGVs

An AGV tugger vehicle is motorized and is designed to tow one or more non-motorized carts, either autonomously or both manually and autonomously. Compared to AGCs, towing AGVs have greater throughput as they are capable of transporting several carts at once, similar to a train. Towing AGVs are also equipped with trays that can be lifted, lowered, with motorized rollers, belts, etc. to enable automatic load transfer.

Heavy Burden Carriers

For the heaviest loads, heavy burden carriers are a type of AGV used in applications such as large assembly, casting, and coil and plate transport. Some heavy burden carriers have self-loading capabilities and may have standard, pivot or Omni-directional steering.

Types of AGV Navigation Systems

Laser Guiding

The AGV is equipped with a rotating laser transmitter and receiver that allows it to detect reflectors mounted in its environment and establish its location with extreme precision. Since they are exceedingly accurate and can allow for product handling to the nearest quarter of a centimeter, they are particularly adapted to medical applications.

Wire Guidance

The AGV is steered along a ground track embedded into the facility floor, that can be composed of wires, tracks, magnetic lines, or cables. The wire transmits a signal that AGVs detect via an antenna or sensor. To implement wire guidance navigation, rails need to be installed. Hence, this navigation system is only recommended for applications that do not require flexibility.

Visual Guidance

Vision-guided AGVs follow a path painted on the ground that its camera recognises. Cameras record features along the route and AGVs rely on these recorded details to navigate. Compared to wire guidance, the cost for visual guiding is lower as it does not require any special installation work.

Geo-guidance

Like vision-guided AGVs, no infrastructure modifications are required for AGVS that use geo-guidance. Geo-guided AGVs recognize and map objects in their environment to establish their location in real-time and navigate independently around the facility, without having to adapt infrastructure. This renders high levels of flexibility for warehouses and production sites.

LiDAR (Light Detection and Ranging)

LiDAR, also referred to as natural navigation, is an advanced navigation technology utilizing sensors that transmit laser pulses to measure the distance between the robot and objects in its environment. This data is compiled to create a 360-degree map of the environment, allowing AGVs to navigate the facility and avoid obstacles without the need for additional infrastructure.

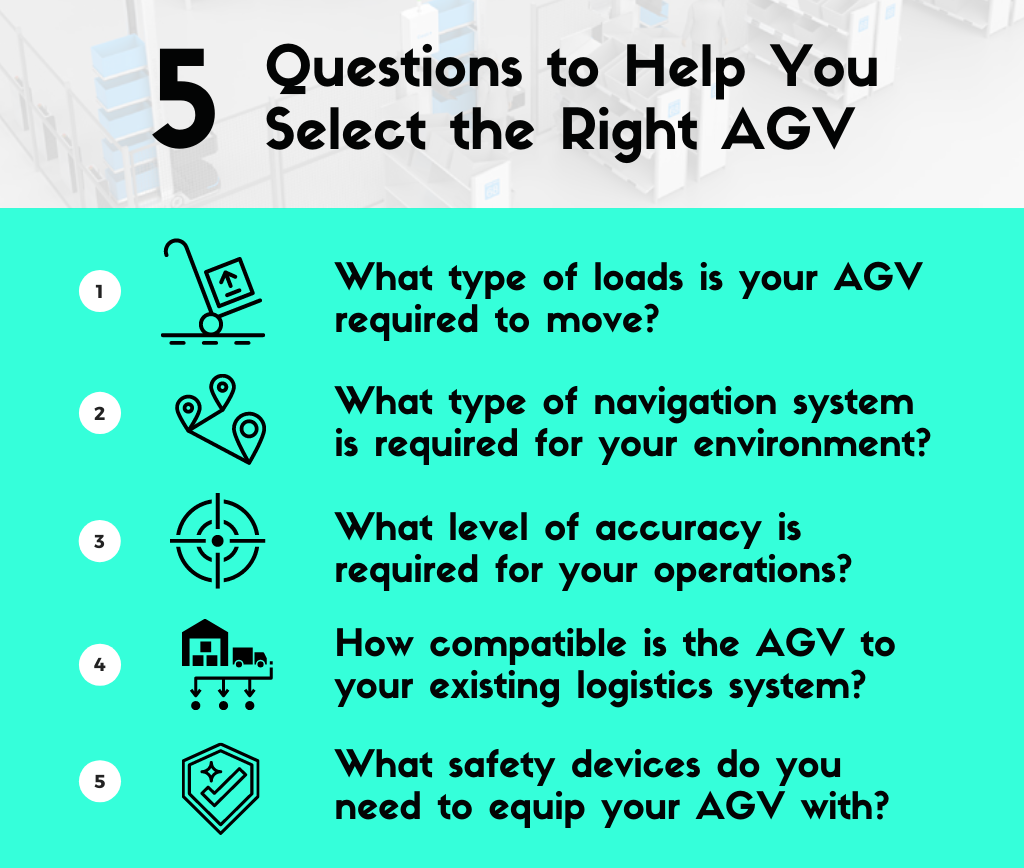

5 Questions to help you select the right AGV

With so many variations of AGVs and navigation systems available on the market, it may overwhelm potential adopters. Before diving into a decision, here are some important questions to consider.

Type of Loads

Whether an AGV is required to move light or heavy loads is an important question to answer since different AGVs have unique payloads. For heavy loads, a bespoke AGV may be a better solution.

Type of Navigation

Depending on the environment the AGV will be operating in e.g., wet, cold, interaction with a human operator, the type of navigation system implemented will differ accordingly.

Level of Accuracy

Ensure that your AGVs are equipped with an appropriate level of accuracy to safeguard loads and circumvent potential damage.

Compatibility with Company’s Logistics System

Since an AGV is part of an automated logistics system, it is paramount that it is congruent with the existing logistics system employed by the business such as the warehouse management system (WMS).

Safety Devices

You can equip your AGV with detection sensors that will halt its movement when it encounters an obstacle. Sound and visual elements can also be built on.

.png?width=1280&name=Questions%20to%20Ask%20AGV%20(1).png) Frequently Asked Question: AGV vs AMR

Frequently Asked Question: AGV vs AMR

Ergo, the choice of an AGV system depends heavily on the task the vehicle is required to execute as well as the complexity of existing or future infrastructure. But are you wondering how do AGVs differ from Automated Mobile Robots (AMRs)? Fret not, as this is a common question asked by prospective adopters of automated solutions. While both technologies optimize material handling and increase the productivity of warehousing facilities, there are differences you should take note of if you are intending to invest in these solutions. To learn more, check out our article here!

.jpg?width=500&name=%E6%89%98%E7%9B%98%E5%88%B0%E4%BA%BA3(1).jpg)