High Storage Density Solutions in the Footwear Industry

In warehousing operations for footwear companies, the two most important considerations are high storage density and high efficiency. Sky Storage & Ground Pick, Geek+'s one-stop four-way shuttle solution, provides a solution for both.

-

High density: At the same shelf height, the storage density is 60% higher than that of traditional very narrow aisle (VNA) shelves

High efficiency: Picking efficiency is 2-3 times that of manual efficiency; with full-pallet picking, the more orders there are, the higher the picking efficiency

High flexibility: It can flexibly match fluctuating production capacity and orders by rapidly adding or removing robots

Saving labor costs: Automatic shelf placement, automatic replenishment, and automated goods-to-person picking allows employees to focus on value-added tasks

Footwear warehousing challenges

-

- High requirements for storage capacity: Compared to other items in the apparel industry, footwear is bulky; therefore, the storage of the same quantity of footwear requires a higher storage capacity

Low picking efficiency: Manual picking selects one pair at a time with one hand, leading to low efficiency

Replenishment timeliness: Stores have limited storage capacity, frequent replenishment, and new updates, and have high requirements for timeliness

Flexibility requirements: When footwear seasons change or special promotions are done, demand fluctuates greatly, so flexibility is a must

Storage and efficiency are difficult to balance

Traditional solutions have problems such as low picking efficiency, low storage density, difficult expansion, and insufficient flexibility, meaning they cannot meet customers’ needs.

|

|

Picking on ordinary heavy-duty shelf |

Picking on VNA heavy-duty racks |

|

Risk |

Shelving and picking are cross-operated, with high safety risks |

The VNA channel is narrow, the forklift operation requires high certifications, and there are operational risks |

|

Capacity |

Wide forklift aisle, single-depth storage, low storage density |

The storage density of the whole pallet is higher, and the storage density of the whole box is lower |

|

Labor |

There is a lot of labor input in each step, and professional forklift workers are required |

High labor requirements, VNA forklift operators with professional certificates are required, and it is difficult to recruit |

|

Efficiency |

The whole pallet and piece picking are operated at the same time, which affects each other and reduces the efficiency; Piece picking requires walking long distances, and the picking efficiency is low |

The equipment operation requires high precision, the operation takes a long time, and the efficiency is low. |

|

Flexibility |

It is difficult to rapidly expand the storage capacity, and the upper limit of picking capacity is low, making it difficult to increase |

VNA layout has very specific on-site requirements, high requirements, complicated construction and a long implementation period |

Geek+ One-stop Four-way Shuttle Solution

Adaptable to business scenarios:

1. B2B scenarios

2. B2B and B2C in the same warehouse

Suitable storage forms:

* Whole pallet storage,

* Whole case storage, and

* Piece storage

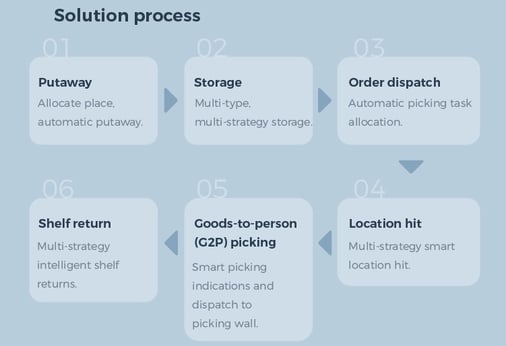

01 Putaway: Allocate place, automatic putaway.

02 Storage: Multi-type, multi-strategy storage.

03 Order dispatch: Automatic picking task allocation.

04 Location hit: Multi-strategy smart location hit.

05 Goods-to-Person (G2P) Picking: Smart picking indications and dispatch to picking wall.

06 Shelf return: Multi-strategy intelligent shelf returns.

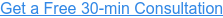

Restocking process

01 Replenishment tasks issued by the system

02 Four-way shuttle system automatic outbound

03 Automatic replenishment of the whole pallet to the G2P area

04 Necessary replenishment picking

05 Unfinished pallets are returned to the four-way shuttle area for storage

06 Manual replenishment to the goods-to-person area

Practical Experience

Geek+ has over 6 years’ practical experience in the apparel industry, is trusted by many industry leaders, and has successfully achieved global expansion through project replication. Its full range of robots can be adopted into a variety of integrated schemes, covering various scenarios in the apparel industry.

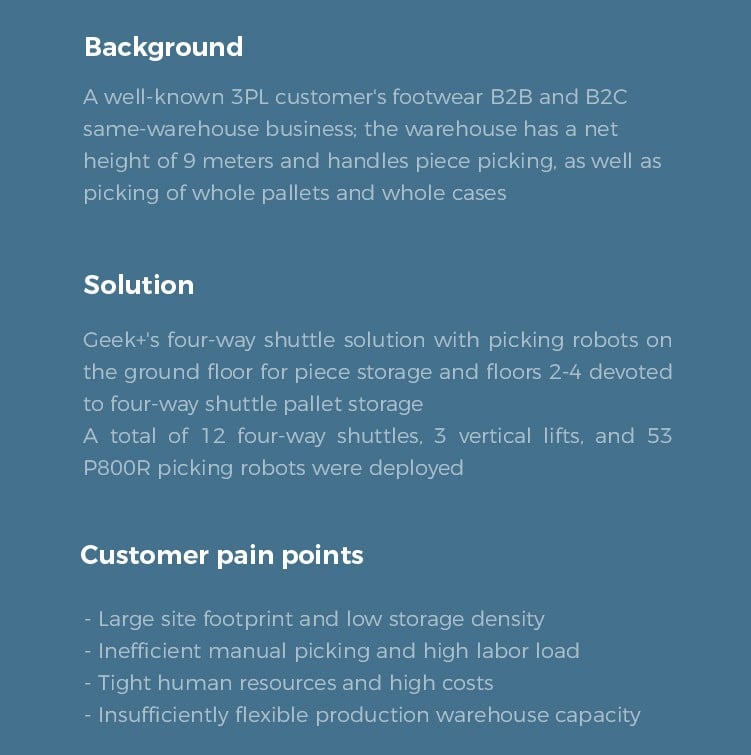

Case Study

Through continuous activity in the apparel industry, Geek+ is accumulating greater understanding and field experience to empower even more apparel customers to achieve intelligent upgrading and transformation.