Automation 101: A "Must" for Choosing ASRS Over AMRs?

You may be aware of Autonomous Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (ASRS), and that these solutions are commonly employed to significantly improve the productivity, flexibility, and safety of operational processes. But do you know that there are in fact many variants of AMRs and ASRS available for different warehousing scenarios? Let’s deep-dive into the alternatives available on the market and their applications today!

Table of Contents:

- Introducing: PopPick

- What is ASRS?

- How does an ASRS actually work?

- Common Applications of ASRS

- What industries are using ASRS?

Introducing: PopPick

One of the latest products to the game - PopPick, a leading-edge robotic automation solution by Geek+, best described as the future of Goods-to-Person, solving issues of efficiency and space by revolutionizing the picking station. In light of the general shortage of labor and space, a growing issue faced by global e-commerce players, the demand for more warehouses is exponentially rising.

PopPick is a long-term solution that can help businesses make the most of available space through intelligent organization and flexible handling of different types of storage units, and labor by optimizing the picking process at the workstation.

So, as a warehouse operators, do they still need to choose ASRS as their final solution? Before deeply diving into PopPick, let's look at our traditional player - ASRS.

What is ASRS?

Automated storage and retrieval systems, otherwise known as ASRS, are computer- and robot-aided warehouse automation technology, specifically designed to independently store and retrieve inventory on demand, in a compact footprint. The system typically consists of predefined locations where machines can follow established routes to obtain items.

An ASRS comprises 4 key components, namely:

An ASRS comprises 4 key components, namely:

- - Storage racks

- - Input/output system

- - Storage and retrieval equipment

- - Warehouse management system

ASRS technology can vary substantially and there are many alternatives suited for a variety of warehousing and manufacturing environments, as well as a wide range of load types. In particular, there are 2 main varieties: Unit-Load ASRS and Mini-Load ASRS.

Between these 2 buckets, there are 6 primary types of ASRS systems namely Unit-Load ASRS Cranes, Mini-Load ASRS Cranes, Shuttle- and Bot-Based ASRS, Carousel-Based ASRS, Vertical Life Module (VLM) ASRS, and Micro-Load (Stocker).

How does an ASRS actually work?

As illustrated above, there are many types of ASRS systems, and each variation operates in slightly different ways to achieve a common goal of improving the efficiency and precision of warehouse processes.

Generally, an ASRS automates the process of storing and retrieving products from appropriate bins, shelves, or other set storage locations, thus reducing the time and manpower needed for these tasks.

Common Applications of ASRS%20(1)-png.png)

What industries are using ASRS?

As there are many variations of ASRS systems available, each with unique capabilities, ASRS systems are well suited for a myriad of industries, with different storage needs. Some industries that can benefit tremendously from ASRS include manufacturing, third-party logistics, pharmaceuticals, e-commerce, retail and automotive.

A Better Alternative for ASRS - PopPick

PopPick is the ultimate Goods-to-Person Solution. The solution has multi-size compatibility to effectively handle items of various sizes with different types of storage units such as totes and cartons.

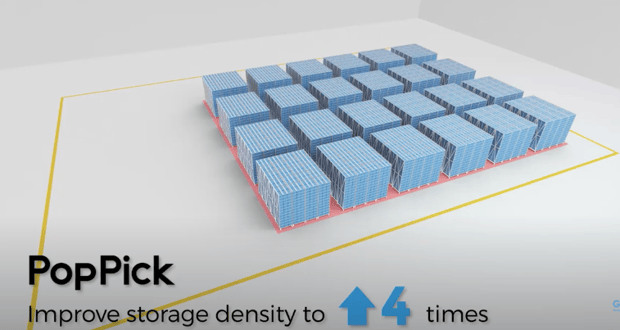

Up to 12 columns of totes are stored densely in an inventory area using pallets or mobile racks of 3.7 meters height for 50% more storage density compared with the original Goods-to-Person system. One rack is optimized to store and transport up to 60 totes, allowing 4x more transportation efficiency.

Once incoming orders are registered, picking robots transfer pallets or mobile racks to a PopPick station where intelligent robot arms effectively retrieve totes or boxes of ordered goods and pass them to the operator via two picking points, enabling higher picking efficiency and thereby, 3x throughput capacity.

Once incoming orders are registered, picking robots transfer pallets or mobile racks to a PopPick station where intelligent robot arms effectively retrieve totes or boxes of ordered goods and pass them to the operator via two picking points, enabling higher picking efficiency and thereby, 3x throughput capacity.

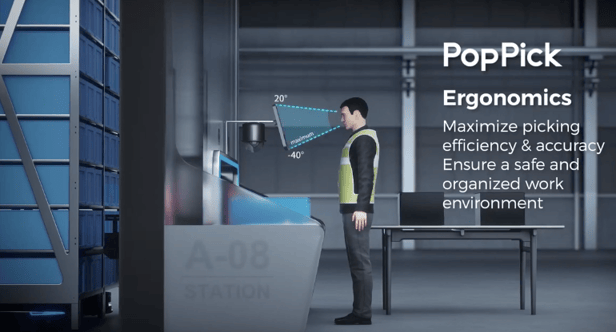

By optimizing the number of robots, and maximizing space utilization (storage density can be improved by 4x) and throughput capacity, PopPick can reduce costs by 50%. Other than gains in business productivity, PopPick also prioritizes worker ergonomics to secure workplace safety and safeguard employee wellbeing.

By optimizing the number of robots, and maximizing space utilization (storage density can be improved by 4x) and throughput capacity, PopPick can reduce costs by 50%. Other than gains in business productivity, PopPick also prioritizes worker ergonomics to secure workplace safety and safeguard employee wellbeing.

AMRs Should be in your Decision Bucket

Today, with AI and Technology advances, we have to consider the new technology applying to your business. And Flexibility is the primary consideration in your warehouse so AMRs is the best choice.

The rise of e-commerce continually accelerates demand for more warehouse space as well as the need for fast and flexible handling of inventory, and unavailable labor. Automated solutions such as PopPick and ASRS can be introduced into facilities to optimize space, bolster productivity, improve picking accuracy, increase inventory control and improve worker ergonomics.

With wide-reaching industry understanding, Geek+ has developed a set of solutions using modular robotics hardware and AI, to help businesses manage complex logistics simply and safely.

Interested in finding out more about our solutions? Click the button to access our white papers or chat with our consultants today!

Found this article helpful? Stay tuned for the third and final part of the series, ‘

.png?width=1095&name=ASRS%20(1).png)

.png?width=500&name=DOES%20YOUR%20SUPPLY%20CHAIN%20NEED%20IT%20(1).png)