Order Fulfillment Optimization Key to Supply Chain Resilience

The Biden Administration has unveiled its Council on Supply Chain Resilience, featuring a broad range of members of his cabinet and other government officials tasked with creating a more robust supply chain. The end goal is to ensure that supply chain backups like the pandemic-era West Coast port disruptions and the trucking capacity crunch don’t occur with any frequency.

Biden’s initial supply chain initiatives include better data sharing among supply chain stakeholders as well as a host of other policies. The Commerce Department will also host a Supply Chain Data and Analytics Summit next year to increase collaboration. Although he didn't mention warehouse fulfillment directly, streamlining activity at distribution centers is crucial to the health of the supply chain ecosystem. Rapid, error-free order fulfillment helps make sure supply chains are functioning well and goods are moving swiftly though the shipment lifecycle.

|

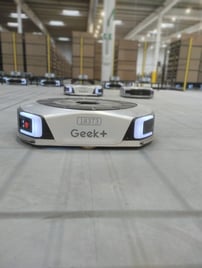

| Utilizing autonomous mobile robots to streamline activity at distribution centers is crucial to the health of the supply chain ecosystem. |

Working together and uniting disparate members of the supply chain is one step in tackling supply chain resilience. The Department of Commerce’s new Supply Chain Center has a remit to undertake “deep-dive analyses on select critical supply chains to drive targeted actions to increase resilience.” A number of the actions take a national security tact toward logistics and are also meant to shore up the supply chain for prescription drugs while making the drug sourcing cheaper.

The Department of Transportation’s Freight Logistics Optimization Works program (FLOW) is also important to the council. In a news release, officials said that partners use information produced through the program to “inform their logistics decision making, helping to avoid bottlenecks, shorten lead times for customers, and enable a more resilient and globally competitive freight network through earlier warnings of supply chain disruption.”

While there was no overt mention of distribution centers among the key announcements and strategic supply chain initiatives, order fulfillment is an important aspect of the supply chain. As e-commerce ordering increases and supply chains are filled more and more with online orders, optimized, error-free picking and order fulfillment can prevent supply chain chokepoints from developing.

Supply chain readiness is also about risk aversion. 3PLs and warehouse operators now have enough post-pandemic data to establish a new normal for their supply chains, but an increasing amount of logistics disruptions – large weather events, geopolitical issues and labor unrest just to name a few – make predictions hard. Fulfillment operations are trying to discover the optimal balance between pre-pandemic lean inventory strategies like just-in-time manufacturing, which created shortages during the early months of the COVID shutdown, and the just-in-case inventory management style. Just-in-time inventory management doesn’t breed supply chain resilience, but having less inventory on hand is one solution to soaring warehouse costs.

Increasingly, optimizing distribution centers and order fulfillment means developing an autonomous mobile robot strategy. The analyst firm Interact Analysis predicts there will be 2.7 million warehouse robots in the

|

| There will be a vast uptick in order fulfillment robot deliveries in the next few years. |

country by 2027 and that more than 60 percent of those will be order fulfillment robots. While just more than 1 percent of distribution centers were using robots by the end of 2022, that number will balloon to 12 percent by the latter half of the decade. That means Shelf-to-Person and Goods-to-Person robots will play a major role in order fulfillment strategies moving forward.

These autonomous mobile robots aren’t replacing workers; robots are used for tasks that workers find too onerous or tiring. Mobile robots aid worker retention while optimizing picking and order fulfillment, all the while reducing errors. It’s all about increasing worker happiness while optimizing warehouse storage. A smart warehouse automation strategy also allows customers to quickly scale up their use of robots for optimization during peak season, even flexibly reorienting automated fulfillment warehouse infrastructure to meet changing customer demands. Distribution center workers are still the backbone of any successful supply chain, so giving them the solutions needed to properly handle an ever-increasing flow of orders needs to be top of mind.

For companies in apparel, e-commerce and other retail industries, warehouse fulfillment during Black Friday and Cyber Monday is all about accurate, fast picking. And thriving in a fast-paced environment is a must. That takes optimized fulfillment processes, but in an era of labor scarcity, a winning retail fulfillment strategy also means attracting temporary workers with good working conditions.

To help with both, retailers and 3PLs are turning toward mobile robot solutions, which help operational efficiency while improving working conditions for employees by reducing strenuous tasks. In an era of thin margins and supply chain disruptions, fast fulfillment, aided by mobile robotic solutions, is a competitive advantage.

.png?width=500&name=ASRS%20(1).png)