What is the Bullwhip Effect and Why it Matters

Beware - have you heard of the phenomenon in supply chain called the Bullwhip Effect (sometimes referred to as the ‘whiplash’ effect)?

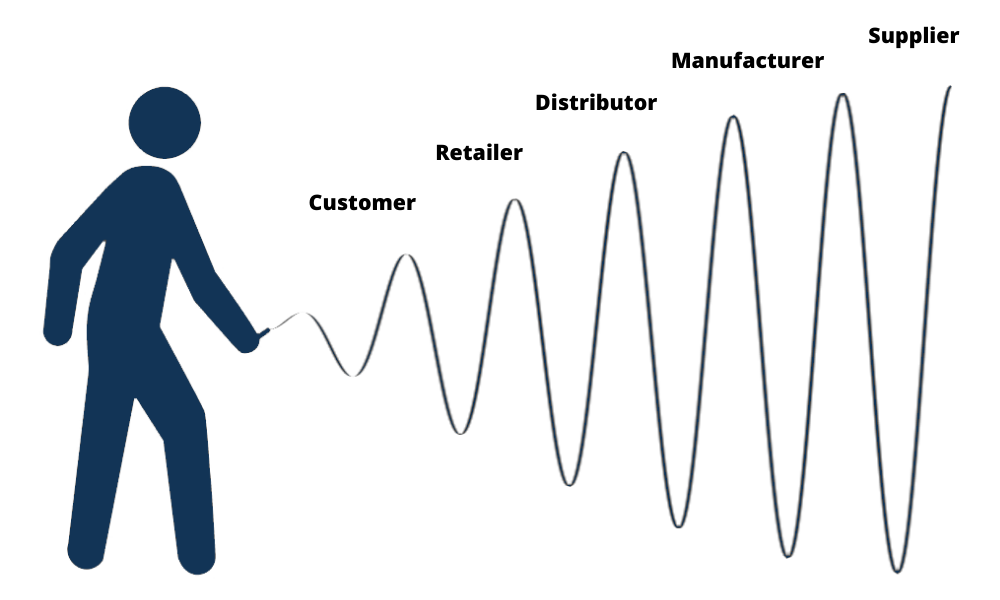

The bullwhip effect is the unexpected distortion of a supply chain caused by a repetitive variation in demand. A typical supply chain is characterized by 5 key players – the customer, retailer, distributor, manufacturer and the supplier. A slight change in customer demand causes unplanned demand from the retailer, which oscillates to the distributor, manufacturer and finally to the supplier, magnifying through each level of the supply chain. The effects of the bullwhip effect can be damaging – unfulfilled orders, excess stock, poor customer service and lost revenue.

Why is it called the Bullwhip effect?

Imagine you are holding a long whip in your hand. You give a little flick to the whip at the handle, which causes it to create little movements in the parts closest to the handle. However, parts of the whip further away from the handle move in an increasing fashion.

Following the natural path of a bullwhip, inventory swings in bigger and bigger "waves" in response to customer demand, which acts as the handle of the whip. The largest "wave" of the whip hits the supplier of raw materials, causing them to see the sharpest demand variation in response to changing customer demand.

What causes the Bullwhip effect?

- Order batching – Order batching is when each member in the supply chain takes order quantities it receives from its downstream customer and rounds up or down to fit production constraints such as equipment setup times or truckload quantities. With order batching, the retailer places orders with its supplier once per month (rather than several times throughout the month), which creates inconsistent demand for the supplier over time.

- Sales and price discounts – Special discounts, promotions and other cost changes can disrupt regular buying patterns. When buyers take advantage on discounts offered during a short time period, it results in irregular production and distorted demand information. This cycle ripples through the supply chain, causing the bullwhip effect.

- Errors in forecasting – Supply chain decisions are made based on demand forecasts. However, relying on past demand information to estimate current demand information of a product does not take into account fluctuations that may occur in demand over a period of time. Errors in forecasting lead to miscalculations that are amplified as they move up the supply chain.

- Lack of communication among stakeholders – This occurs when managers deduce product demand differently within different links of the supply chain and thus order different quantities, which are often smaller or larger amounts than what is required. This lack of communication results in misaligned perceptions and reactions to projected demand.

Why does the Bullwhip Effect matter?

The bullwhip effect can lead to many problems in the supply chain which can prove costly to companies. Overstated or understated orders based on misguided forecasts can directly lead to incorrect inventory levels.

A surplus of inventory could prove costly to the company which may have to fork out extra for inventory holding costs. There is also the risk of expiring goods for perishable products.

.png?width=1000&name=%E6%9C%AA%E5%91%BD%E5%90%8D%20%E7%9A%84%E8%A4%87%E6%9C%AC%20(2).png)

On the other hand, a shortage of inventory translates to lost sales, revenue, reduced customer satisfaction and potential contractual penalties.

.png?width=1000&name=%E6%9C%AA%E5%91%BD%E5%90%8D%20%E7%9A%84%E8%A4%87%E6%9C%AC%20(3).png)

As more businesses understand the risks and consequences of the bullwhip effect, they will seek out measures to mitigate the potential impact of such a phenomena on their supply chain.

Stay tuned for our upcoming article where we will explore what businesses can do to minimize the occurrence of the bullwhip effect on their supply chain.

About Geekplus

Geekplus is a global leader in mobile robotics technologies. We develop innovative robotics solutions for order fulfilment. More than 850 global industry leaders use our solutions to realize flexible, reliable, and highly efficient automation for warehouses and supply chain management.

Media Contact

Marie Peterson, VP International Marketing & Communications

Marie.peterson@geekplus.com

About Geekplus

Geekplus is a global leader in mobile robotics technologies. We develop innovative robotics solutions for order fulfilment. More than 850 global industry leaders use our solutions to realize flexible, reliable, and highly efficient automation for warehouses and supply chain management.

Media Contact

Marie Peterson, VP International Marketing & Communications

marie.peterson@geekplus.com