Join the Automation Movement before 2020, Geek+ to Exhibit Intelligent Robots at IMHX UK

The rise of Ecommerce and demand for fast delivery has forced warehouse operators to significantly enhance the entire warehouse efficiency. According to the BIS research, the numbers of mobile robots will have doubled by 2023. For fast moving industries with high SKUs in particular, demand for robots will drastically surge. The reason behind this trend is both the labour issues and market demand.

For labour, in addition to consistently rising labour costs as well as increasingly stringent rules, there is an increasing shortage of warehouse workers, a headache to the entire logistics industry. In the US, for example, there will be a shortfall of 1 million warehouse workers by 2022. These labour issues constitute continuous overhead and efficiency problems to warehouse operators.

On the other hand, demand for“flawless” and fast delivery is becoming a standard across the logistics industry. Customers are expecting a shorter and shorter delivery period. New approaches like Last-Mile-Delivery are striving to keep pace with demands of Ecommerce. This standard of delivery is expected become higher than ever before.

Simply because of these two factors, warehouse operators are already struggling with coping with the new delivery standard.

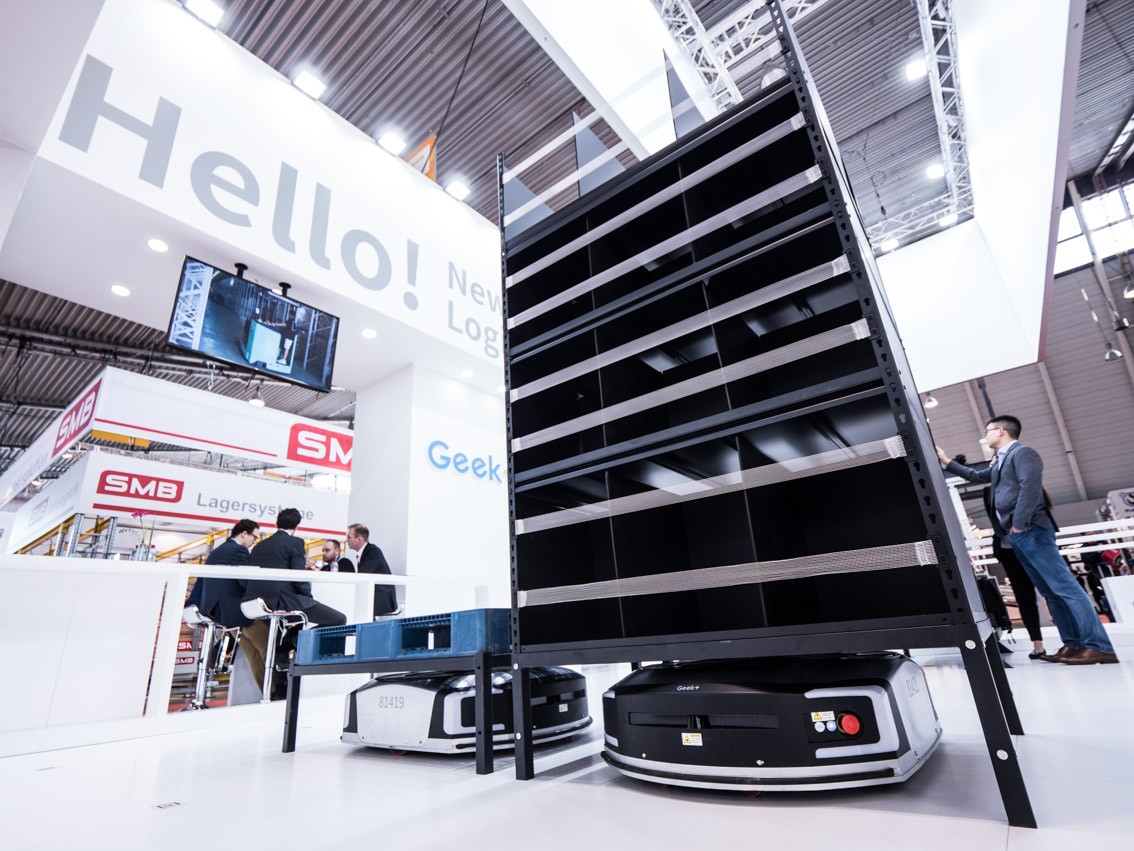

Geek+ has developed the technology to significantly alleviate the headache of warehouse operators. Geek+ will participate in IMHX, one of the largest logistic events in the UK and exhibit its latest robotic solutions such as the Sorting solution S20C. Geek+ specializes in providing advanced robotics technologies solutions to logistics with over 200 projects and 7000 robots deployed globally.

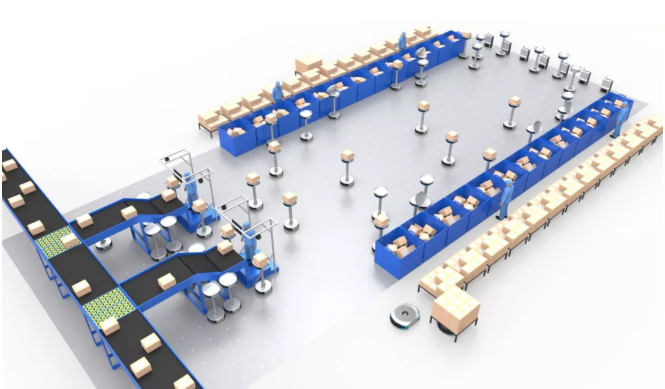

The MiniSort S20C uses the Geek+ S20 line of robots as sorting and transportation devices. Sorting holes can be freely distributed around the edge of the site, and the system is characterized by its high efficiency, reduced labour, and modularization. MiniSort can design a sorting environment based on the actual site requirements of the client, and it is highly adaptable to site locations; No need for fixed platforms and suitable for quick installation. Customers can flexibly expand and adjust sites, destinations, and efficiency based on the crests and troughs of the sorting traffic.

The Geek+ Picking system will also be one the featured solution at the event, which has automated the order picking process. The most inefficient process for warehouse workers is working through the aisles and picking the corresponding SKUs. This traditional approach wastes too much time to pick it out and is very labour intensive. Automation solutions like the picking system enhances the accuracy from normally 70% to 99%.

Geek+ is not only manufacturing the robots, but making them intelligent, enabling them to self-correct and self-determine their optimal operational mode.

If you are one of the market drivers in your industry, you should not miss out on automation and Geek+'s market defining technology. In the era of intelligence, it will be the make-or-break difference between you and your competitors in the coming years.

If you are one of the market drivers in your industry, you should not miss out on automation and Geek+'s market defining technology. In the era of intelligence, it will be the make-or-break difference between you and your competitors in the coming years.

Schedule a meeting with our consultants at here or Visit our stand at 6E255 in IMHX to learn more.

About Geekplus

Geekplus is a global leader in mobile robotics technologies. We develop innovative robotics solutions for order fulfilment. More than 850 global industry leaders use our solutions to realize flexible, reliable, and highly efficient automation for warehouses and supply chain management.

Media Contact

Marie Peterson, VP International Marketing & Communications

Marie.peterson@geekplus.com