3PL Grocery Fulfillment Solutions

Smart Brownfield Solutions for Modern Warehouses

Leverage PTP systems designed for seamless integration into brownfield sites, supported by segregated aisles and cutting-edge robotic technologies like reach truck lifts and P800s.

Trusted by 770+ Global Customers

Client-Specific and Dynamic Demands

Demand FluctuationsHandling peaks and troughs in customer orders, especially during promotional cycles or holidays. |

SKU DiversityUnpredictable demand patterns requiring rapid inventory adjustments and fulfillment adaptations. |

Adapting to SLAs

Meeting diverse client-specific service-level agreements, including strict delivery timelines and accuracy. |

Operational AgilityAdjusting fulfillment strategies on the fly to adapt to fast-changing demand trends. |

Cost ManagementBalancing operational costs with the need to meet performance benchmarks set by clients. |

Technology IntegrationLeveraging technology to improve efficiency in inventory management and real-time delivery tracking. |

Smart Brownfield Solutions for Modern Warehouses

Shelf-to-Person System

Automation configured for efficiency in space-limited sites.

✅ Adapts seamlessly to existing site constraints

✅ Boosts throughput for multiple SKUs regardless of size and type

✅ Responds proactively to fluctuating demand patterns

✅ Eases installation with versatile, modular design options

Tote-to-Person

Flexible configurations for improved workflow in constrained spaces.

✅ Segregated aisles for easier access and order routing

✅ Optimizes space utilization for varying aisle and SKU densities

✅ Ensures forklift and robotic workflows operate harmoniously

✅ Reduces congestion for higher productivity during peak activity

Pallet-to-Person

Next-generation robotic solutions for high-accuracy execution.

✅ Ensures prompt movement across designated fulfillment routes

✅ Manages diverse inventory portfolios with speed and precision

✅ Enhances workload balancing across shifts and zones

✅ Provides real-time insights on robotic efficiency via integrated apps

.gif?width=600&height=342&name=640%20(3).gif)

Unified Software

Combining human and machine touchpoints for peak output.

✅ Incorporates collaborative setups in mixed-use facilities

✅ Delivers high accuracy rates in SKU-specific picking processes

✅ Supports automation during high-frequency orders

✅ Offers scaling pace based on client demands or peak periods

Sample Layout

Streamlined design tailored for smooth, scalable performance.

✅ Shelf-To-Person workflow for store-level selection of headers

✅ Smart zoning for receiving, pallet storage, and outbound flows

✅ Consolidated systems for multi-header and single-header selections at selection station

✅ Dual-Presentation at Selection Station for continuous flow of operations

Measurable Improvements for Your 3PL Grocery Operations

<300%Increased ThroughputProcess more orders with fewer resources, allowing you to handle volume spikes and growth without adding warehouse space. |

65% ↓Faster Order FulfillmentCut order processing times to meet tight delivery windows and ensure stores receive stock when they need it. |

40% ↓Lower Operational CostsReduce labor costs, minimize errors, and optimize space utilization for significant operational savings. |

99.9%Improved Inventory AccuracyNear-perfect inventory tracking reduces out-of-stocks and overstocks that impact store operations. |

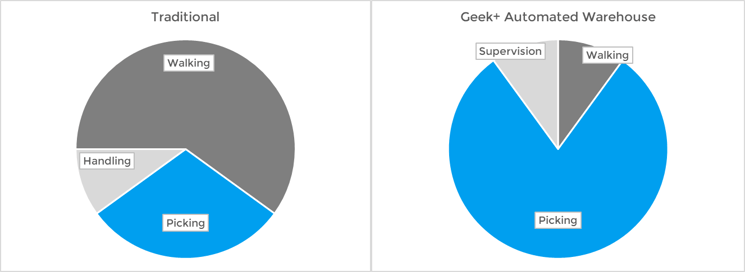

70% ↓Labor OptimizationReallocate staff from repetitive manual tasks to higher-value activities that enhance customer experience. |

4xEnhanced AdaptabilityQuickly adjust to changing demand patterns, new product introductions, and seasonal variations. |

Trusted by Leading 3PL Grocery Providers

ASDA

Sort up to 2000 parcels/hour

✅Geekplus deployed 60 S20C sorting robots in ASDA's 3,875 sqft. cross-docking facility. Geekplus solutions provided ASDA the ability to flexibly respond to rapid changes in order volume to ensure better customer service during peak times.

✅ Increased operational flexibility by over 65% and sorting efficiency up to 2000 parcels/hour.

Wellcome

2x Operational Efficiency

✅ Wellcome integrated Geekplus's Shelf-to-Person and Skycube solutions into its 20,000-square-foot facility to build its first automated smart warehouse in Hong Kong.

✅ Achieved operational efficiency by two times and long-term cost savings by maximizing vertical space for high-density pallet storage.

Lianhua Supermarket

2x storage capacity

✅ To meet rising demand across more than 5,000 grocery stores, Lianhua Supermarket integrated Geekplus Pallet-to-Person solutions in its smart warehouse distribution center, serving more than 90 urban locations.

✅ Optimized vertical space with multi-level pallet storage, and doubled storage capacity to handle 80,000 SKUs.

I'm really proud to see Geekplus systems performing so well. They are delivering great results and hitting the key metrics.

With Geekplus Shelf-to-Person solutions in place, our warehouse team members no longer need to manually search for products. Our order fulfillment is now fast and accurate, making operations more effortless than ever.