C-Store Fulfillment Solutions

C-Store Fulfillment Challenges and Automation Solutions

Tailored automation solutions for C-Store supply chains facing SKU complexity, labor shortages, and rapid replenishment demands.

Trusted by 770+ Global Customers

Addressing the Unique Challenges of C-Store Supply Chains

SKU ProliferationManaging thousands of diverse SKUs with different ambient, chilled and frozen temperature, handling, and storage requirements. |

Demand VolatilityUnpredictable demand patterns requiring rapid inventory adjustments and fulfillment adaptations. |

Rapid ReplenishmentNeed for daily or multiple-times-per-week store deliveries with tight delivery windows. |

Labor ShortagesDifficulty finding and retaining warehouse staff for repetitive picking and packing tasks. |

Distribution ComplexitySupporting growing delivery networks across urban, suburban, and rural locations. |

Seasonal PressuresManaging seasonal surges and promotional events that create temporary volume spikes. |

Purpose-Built Solutions for Grocery Operations

Shelf-to-Person System

Fast-moving shelf inventory, brought directly to the picker.

✅ Perfect for split-case picking of snacks, beverages, and everyday essentials

✅ Flexible layouts for narrow aisles and mixed-SKU storage

✅ Increases picking speed for high-throughput convenience replenishment

✅ Reduces store-order errors with automated shelf delivery

Tote-to-Person System

High-density vetical storage for fast-turning goods.

✅ Ideal for small and medium sized , personal care, OTC, high-margin items etc

✅ Double robot design speeds up retrieval and order consolidation

✅ Handles seasonal surges and store-level order complexity with ease

✅ Space-efficient design fits into urban or back-of-store operations

Pallet-to-Person System

Full pallet and case movement for grocery DCs and chilled zones.

✅ Handles fresh, chilled, and frozen goods with multi-zone handoff

✅ Ideal for regional distribution centers and cross-docking hubs

✅ Reduces forklift dependency and cold zone exposure

✅ Increases safety and efficiency in ambient-to-frozen environments

.gif?width=600&height=342&name=640%20(3).gif)

Warehouse Software Suite

Real-time fulfillment intelligence for every convenience and grocery SKU.

✅ Automates order batching, route optimization, and SKU slotting

✅ Tracks performance across chilled, ambient, and seasonal inventory

✅ Seamlessly integrates with retail and grocery WMS/ERP

✅ Provides store-level insights to optimize replenishment cycles

Sample Layout: AMR-Powered Fulfillment for Convenience Stores

Sample Layout: AMR-Powered Fulfillment for Convenience Stores

A real-world example of a robotic layout optimized for high-frequency, small-format retail.

✅ Tote-to-Person (TTP) area for fast-moving SKUs

✅ VAS and expedited order zones for expedidhandling

✅ Smart zoning for pallet racks, picking, and receiving

✅ Consolidation and wrapping area for outbound flow

✅ PDA stations for real-time replenishment and inventory sync

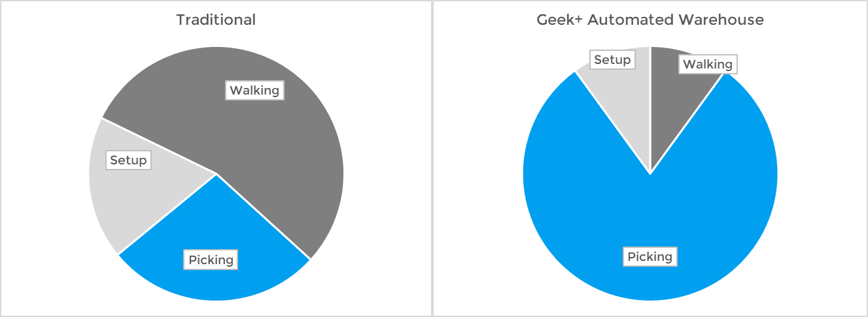

Measurable Improvements for Your Grocery Operations

<300%Increased ThroughputProcess more orders with fewer resources, allowing you to handle volume spikes and growth without adding warehouse space. |

65% ↓Faster Order FulfillmentCut order processing times to meet tight delivery windows and ensure stores receive stock when they need it. |

40% ↓Lower Operational CostsReduce labor costs, minimize errors, and optimize space utilization for significant operational savings. |

99.9%Improved Inventory AccuracyNear-perfect inventory tracking reduces out-of-stocks and overstocks that impact store operations. |

70% ↓Labor OptimizationReallocate staff from repetitive manual tasks to higher-value activities that enhance customer experience. |

4xEnhanced AdaptabilityQuickly adjust to changing demand patterns, new product introductions, and seasonal variations. |

Trusted by Leading Grocery Operators

Circle K

Largest Smart Warehouse for Grocery Deliveries in Asia

✅ 100 Shelf-to-Person picking robots were deployed in Circle K’s 140,000 sq. ft distribution center to handle the deliveries of more than 300 Circle K convenience stores.

✅ Improved space utilization, throughput capacity and brought more flexible supply chain operations.

Century Mart

2x storage capacity

✅ To meet rising demand across more than 5,000 grocery stores, Lianhua Supermarket integrated Geekplus Pallet-to-Person solutions in its smart warehouse distribution center, serving more than 90 urban locations.

✅ Optimized vertical space with multi-level pallet storage, and doubled storage capacity to handle 80,000 SKUs.

Wellcome

2x Operational Efficiency

✅ Wellcome integrated Geekplus's Shelf-to-Person and Skycube solutions into its 20,000-square-foot facility to build its first automated smart warehouse in Hong Kong.

✅ Achieved operational efficiency by two times and long-term cost savings by maximizing vertical space for high-density pallet storage.

C-StoreMaster

4x Full Warehouse Orders

✅ To automate its new 130,000-square-foot warehouse in Alabama, C-StoreMaster implemented Geekplus flagship P800 Shelf-to-Person solutions along with the award-winning RoboShuttle system.

✅ Doubled inventory density and enhanced picking productivity by four times.

Walmart

Multinational retail corporation and the number 1 Fortune 500 company.

✅Geek+ robots help Walmart easily handle their massive quantity of SKUs, improving their picking efficiency by about 3.5 times

✅Geek+ deployed picking robots used for loading and unloading shelves, replenishing shelves, inventory, and performing outbound operations according to order instructions.

✅ Productivity increased from 149 pieces/person/hour to 533 pieces per person/hour

We aim to improve our customer and employee experience by reinventing our supply chain management with Geek+ automation technologies

We cherish the collaboration with our business partner Geek+ and we work closely to offer relevant products and promotions to our customers with good value

With Geekplus Shelf-to-Person solutions in place, our warehouse team members no longer need to manually search for products. Our order fulfillment is now fast and accurate, making operations more effortless than ever.

Innovation has always been at the forefront of our business and with this new warehouse, C-StoreMaster is set up for success for years to come.