RoboShuttle™: 3 Things You Need to Know

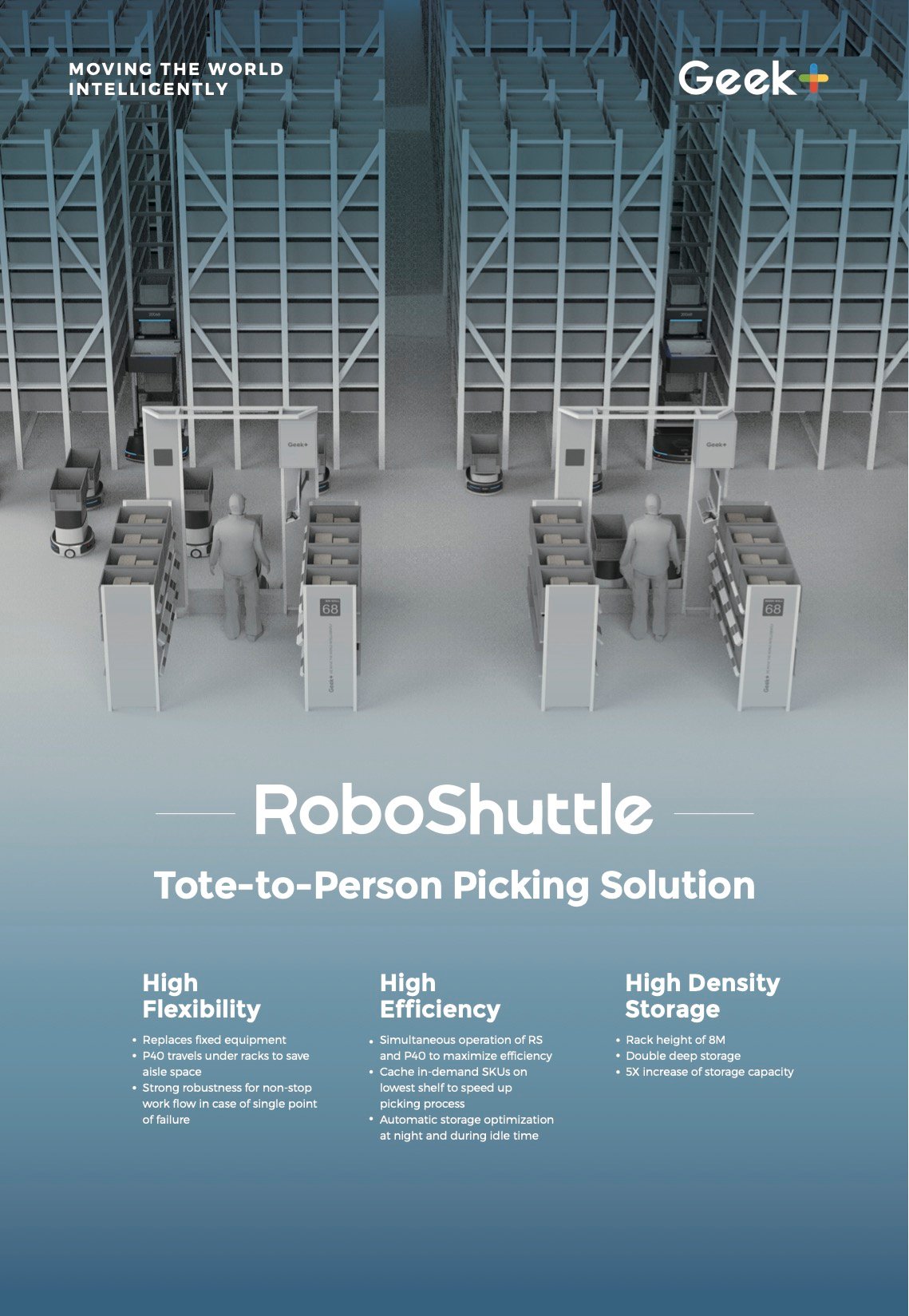

RoboShuttle™ is a next-generation, high storage density, tote-to-person picking solution with optimal cost efficiency and robust operational flexibility.

A tote-carrying robot equipped with a lifting module that adjusts the tote to a suitable height for the operators, enabling an ergonomic work process which increases picking efficiency. P40 is 20% faster with quicker acceleration speeds than similar products and can travel under racks to save aisle space. Combined with RoboShuttle™, the two robots form a fully flexible tote-to-person picking solution.

The basic concept behind the Tote-to-Person solution known as RoboShuttle™, is to help businesses take full advantage of vertical warehouse space. This system ensures safe storage, retrieval, and organization that optimizes warehouse space.

When a new box is placed on a rack, the robot will carry it to the operators or shelf. The robot will use a lifting module to adjust the height of the box. This allows RoboShuttle™, to work independently optimizing value time and resources.

1) An Award-winning Solution:

The Geek+ RoboShuttle™ system was certified as "Best of Intralogistics 2020" by the world-renowned IFOY award, one of the industry's most prestigious recognitions.

2)Super Fast ROI:

Compared with the traditional warehouse shuttle system, RoboShuttle™ has higher flexibility, efficiency and return-on-investment. Its AI algorithm will also detect different box sizes to maximize space. Its low operating costs allow it to reduce the need for a manual warehouse, which is one of the main causes of increasing rental costs.

3) Highly Flexible:

The RoboShuttle™ is compatible with several types of bins, totes, cartons, and boxes. It is highly flexible with a slim chassis and doorframe and is equipped with double deep telescopic fork arms. It is also equipped with an intelligent depth camera and high-precision sensors, which help it avoid obstacles. Its compact, robust chassis design allows it to be placed in confined areas. Its wide-range sensors allow it to identify objects and identify them even when jumbled. It is designed to work with a variety of materials, including cardboard and tyres, making it ideal for warehouses.

It is an excellent option for a small- to medium-sized warehouse and will make the process faster and safer. The main benefits of using RoboShuttle™ are its safety, flexibility, and low maintenance.

The Double Deep RoboShuttle™ is designed to operate in narrow aisles and reach 5m-high shelves. It can accommodate totes of different depths. With high-precision sensors, it can operate in varying ground conditions and in different types of warehouses. Its adjustable arm design and multi-level storage capability also make it an ideal solution for warehouses.

Applicable Industries: apparel, pharmaceuticals, retail, e-commerce P40: flexible and convenient

"With e-commerce and warehouse rental spikes, businesses need a flexibility and space utilization that traditional automation does not provide. Our engineering teams are continuously developing innovative solutions to meet this demand and allow our clients to remain competitive while providing a safe working environment to their employees."

-Liu Kai, Co-founder and VP of smart warehouse products at Geek+

Connect with Geek+ on Linkedin to stay in touch with RoboShuttle News

.png?width=500&name=With%20Automation)