Geek+ Robots: at the Heart of the Logistics Revolution

As one of the largest economies in Europe, France is a key market for Geek+, with several major projects already underway. France-based Geek+ Global Key Account Director Alexis Richez sat down with logistics journalist Emilien Villeroy from Voxlog, a French publication focused on the supply chain, to discuss the advantages Geek+’s technology can bring, some of our latest developments, and what logistics trends are emerging. Read on for some of the highlights of their conversation:

Photo:Geek+ Global Key Account Director Alexis Richez

Photo:Geek+ Global Key Account Director Alexis Richez

Emilien Villeroy: As things stand today, how can robotic solutions respond to warehousing needs in terms of labor, energy independence, and productivity?

Alexis Richez : We are currently seeing an increasing shortage of labor as people are refusing to do jobs involving hard tasks like walking a lot or lifting heavy loads, so it’s getting harder to retain workers. Also, thanks to inflation, it’s getting harder and more expensive to find and retain.

"Bringing in robots and digitalizing the warehouse makes workers’ jobs more attractive. They go from simply being providers of physical labor to supervisors of a fleet of robots and are freed to do more value-adding tasks," said Richez. "It’s a win-win situation. Employees skillsets are enriched while their jobs become much more comfortable, creating a much better working environment overall."

Also, in a robot-powered warehouse, the areas where the robots operate are closed off, meaning that it's generally not necessary to heat them or light them, which translates into significant advantages for the general functioning of the warehouse especially in terms of energy. We estimate that some of our clients have saved as much as 75% in energy costs in areas dedicated solely to the robots.

EV: So automation has become something of a standard for actors in the logistics sector?

AR: It's becoming the norm simply because the evolving consumer demands - faster deliveries, peak seasons - have made exceptions the norm. This means logistics has had to respond to meet those demands, and that means turning to robots. Using robots turns a warehouse into a digitalized space where various tasks become much simpler. I'll give you a few examples.

First, what we call automation on demand really shows the flexibility and scalability that our solutions provide. The process of automating a warehouse is often done in phases; the number of robots or racks can be adjusted up or down according to business fluctuations.

In a fully automated warehouse, inventory is taken every day. We can see in real time what is in the warehouse and quickly respond to issues either in terms of items not selling or moving more quickly than anticipated.

There is also dynamic slotting, which places the racks in positions according to order forecasts. The system takes advantage of downtime to reorganize the stocks in the shelves to increase picking efficiency.

EV: In what ways could Geek+’s solutions play a role in future logistics revolutions and using what technologies?

AR: "Geek+ has the double advantage of having the ability to building robots and also the know-how to use them effectively and optimize their implementation. We're talking about connected logistics systems with enormous amounts of data," said Richez. "Geek+ has over 20,000 robots deployed around the world, and the accumulation of data and experience from all our projects means that even a new client is not starting from a blank slate; they benefit from the optimization of software and algorithms tested in the real world in addition to solutions customized to suit their unique needs."

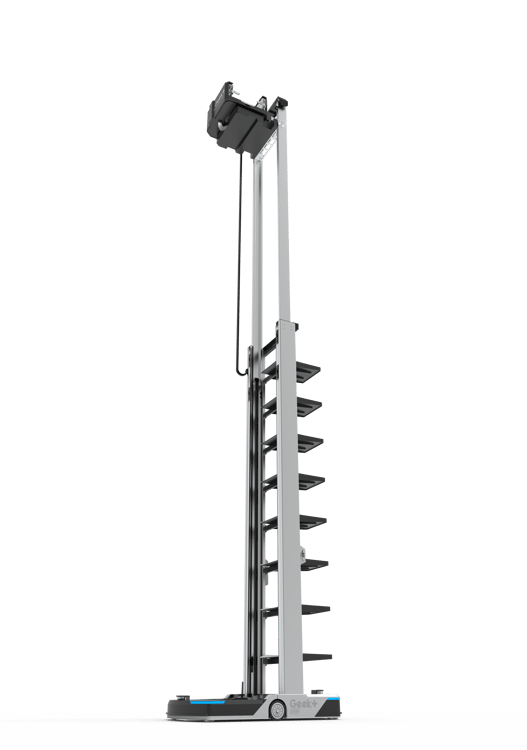

We are very strong in goods-to-person--moving cartons, shelves, or pallets to pickers who fulfill the orders - and we also have robots that handle very high vertical storage space. Our RoboShuttle robots navigate through aisles to find the needed items, bring them to floor level, where another robot takes the carton to the picking station. This is a very typical situation of robotic cooperation between four or even five robots handling different tasks.

Photo: RoboShuttle8

EV: Among your recent developments is the PopPick solution. Can you tell us more about this solution?

AR: PopPick is our latest (goods-to-person) solution, which has just arrived in Europe. PopPick is based around an automated picking station. Rather than having a warehouse employee search through a rack of cartons to find the right item, the PopPick station is fed with mobile racks (carried by picking robots), and its robot arms grab the necessary carton and present it to the operator. This reduces the chance for errors and greatly boosts productivity because all that's left to do is check the quantities involved. PopPick also works with the dynamic slotting we talked about earlier and can reorganize the stocks in the shelves.

With manual picking, an operator might be able to pick one hundred orders per hour, with goods-to-person, we're talking about two, three, or even four hundred orders per hour with very good operators. PopPick can do 600 or 650 picks per hour. This allows for major gains in productivity and efficiency.

Photo: The PopPick workstation

EV: Today, robotics allows us to imagine new forms of work. What models are you seeing emerge in the world of intralogistics?

AR: I can think of one clear example from everyday life: grocery shopping. Today, there are so many ways of doing your grocery shopping, whether you go to the shop yourself or have groceries delivered. And there's a new way that's showing up more frequently. You place an order on your smartphone, and the warehouse itself will prepare the goods and make them ready for pick-up, meaning that all you need to do is go in and pick up what you've ordered. That's possible 24 hours a day. We call these micro-fulfillment centers (MFCs); they're basically mini-warehouses. They're adaptable, for example, in cities where space is limited, and they allow people to do their shopping exactly when they want.

EV : So, it's a way of using robots in an urban setting, closer to the needs of online shoppers?

AR: Exactly, and to create a sort of hybrid warehouse that can prepare orders, and, with an integrated pick-up area, become a giant automatic distribution center. I think we're going to see more and more such scenarios, because the line between warehousing and retail is becoming more blurry, especially in big cities.

To hear the full version of Emilien and Alexis’s conversation (in French), click here.