Cross-Docking Grocery Fulfillment Solutions

Customized Cross-Docking Automation for Grocery Operations

Fewer touches, faster pallet movement, and smarter fulfillment with Geekplus robotics solutions

Trusted by 770+ Global Customers

Labor and Scalability Constraints

Wholesalers face mounting pressure to optimize labor and logistics while overcoming operational obstacles tied to space, efficiency, and perishables.

Labor ShortagesFinding and retaining workers for repetitive tasks remains a significant hurdle. |

Scalability Issues

Managing a broad portfolio of SKUs with varying storage and transportation requirements. |

High Real Estate CostsSkyrocketing property prices make it difficult to secure larger facilities. |

Inventory AccuracyManual tasks often lead to errors in stock tracking, increasing the risk of shortages. |

Perishables ManagementManaging temperature-sensitive goods while preventing spoilage and adhering to safety regulations adds complexity. |

Delivery SpeedMeeting retailers’ demands for rapid restocking requires optimized transportation and fulfillment processes. |

Cross-Docking Solutions for Grocery Wholesalers

Geekplus cross-docking solutions leverage Shelf-to-Person systems to automate the flow from inbound to outbound with speed and precision.

Shelf-to-Person System

Seamless automation flow across receiving, storage, and shipping.

✅ Adapts to existing warehouse layouts with minimal disruptions

✅ Dual-mode operation ensures order fulfillment across SKU ranges

✅ Reduces operational costs with targeted workflow adjustments

✅ Facilitates rapid implementation for short-term ROI gains

Pallet-to-Person

Enhanced access to inventory within complex architecture.

✅ Speeds up stock movement in vertically stacked warehouses

✅ Provides efficiency across high-density urban storage areas

✅ Lowers manual handling risks with automated retrieval

✅ Ideal for chilled, frozen, and ambient products

.gif?width=600&height=342&name=640%20(3).gif)

Unified Software

Advanced robotics for high-performance fulfillment.

✅ Robots streamline order processing with automated sorting systems

✅ Double-tier systems manage increased vertical utilization

✅ Handles higher SKUs while reducing floor space requirements

✅ Enhances overall throughput during peak demand

Sample Layout: Cross-Docking Automation for Grocery Wholesalers

Real-world layout optimization for operational success.

✅Pallet receiving and handling automated by Geekplus mobile robots

✅ Optimized warehouse space through shared inbound and outbound dynamic zones

✅ Centralized system with AI-assisted scheduling

Measurable Improvements for Grocery Wholesalers

<300%Increased ThroughputProcess more orders with fewer resources, allowing you to handle volume spikes and growth without adding warehouse space. |

65% ↓Faster Order FulfillmentCut order processing times to meet tight delivery windows and ensure stores receive stock when they need it. |

40% ↓Lower Operational CostsReduce labor costs, minimize errors, and optimize space utilization for significant operational savings. |

99.9%Improved Inventory AccuracyNear-perfect inventory tracking reduces out-of-stocks and overstocks that impact store operations. |

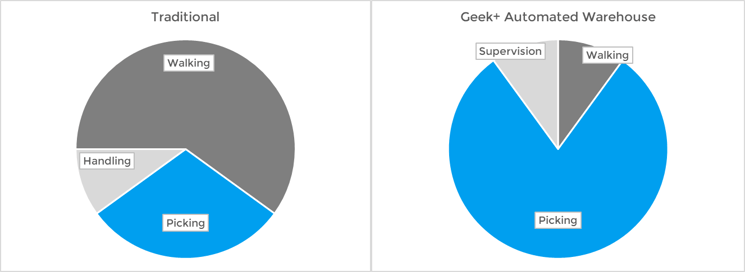

70% ↓Labor OptimizationReallocate staff from repetitive manual tasks to higher-value activities that enhance customer experience. |

4xEnhanced AdaptabilityQuickly adjust to changing demand patterns, new product introductions, and seasonal variations. |

Trusted by Leading Grocery Wholesalers

The Largest Grocery Retailer in the UK

Customized cross-docking automation for Britain's largest grocery retailer

✅Geekplus implemented a cross-docking solution using 70 shelf-to-person picking robots in a 38,823 sq ft warehouse in the UK

✅ Improved picking productivity while easing manual workload operations

✅ A dynamic sorting and storage area designed for operational scalability and flexibility

A Leading Supermarket Chain

Automated cross-docking solution for a global supermarket leader

✅ Geekplus designed a scalable cross-docking solution utilizing Shelf-to-Person robotics system to optimize the customer's warehouse throughput

✅ Achieved greater operational efficiency through improved picking accuracy and workflow optimization