Bin-to-Person vs Goods-to-Person

Many are familiar with the term ‘goods-to-person’ but do you know what “bin-to-person” entails? Bin-to-person picking is a revolutionary picking solution that combines narrow aisle design to achieve high-density storage while maintaining high levels of efficiency. The cornerstone of this novel bin handling is its accompanying flexibility, which can allow businesses to easily adjust their picking strategies according to fluctuating demands while maximizing their productivity.

What are the common headaches warehouse operators face?

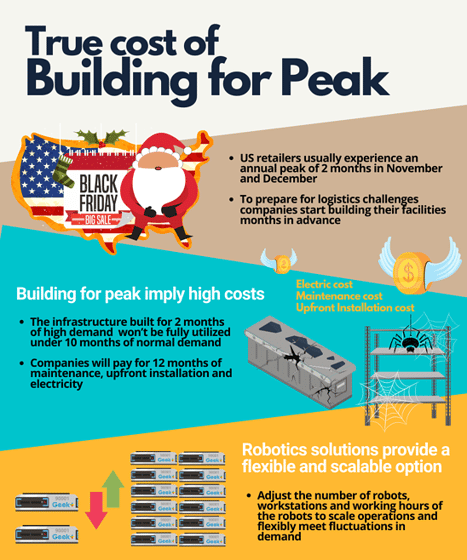

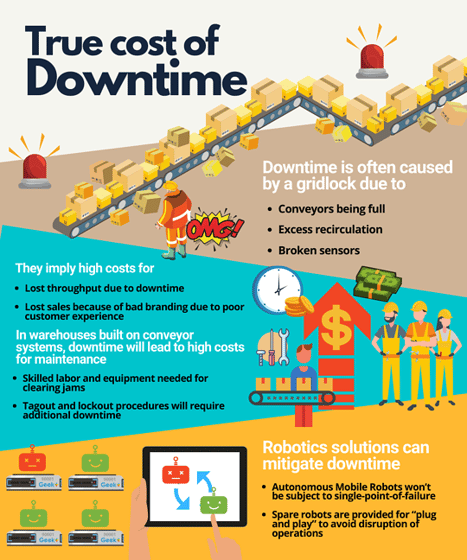

Before diving into the details of bin-to-person picking, let’s iron out the basics: bins are a common form of material containers in the logistics industry. While traditional automatic solutions used for material handling have a high inventory utilization rate and warehousing efficiency, they are generally costly and inflexible. Here are two headaches warehouse operators face:

Single Point of Failure

Traditional automatic solutions are susceptible to single points of failure, which can culminate in bottlenecks and potential business shutdown. Because of this common pain point faced by the industry, many manufacturers have launched bin robots, which are versatile to overcome the rigidity of traditional solutions.

Rental Cost of Warehouse

Since warehouse rental costs are on the rise and represent more than 40% of overall operating costs, bin-to-person picking solutions can aid businesses in realizing flexible, smart upgrades to meet short-term demands whilst propelling long-term growth.

(Another Headaches Operators Encountered)

4 Types of Bin-to-person systems

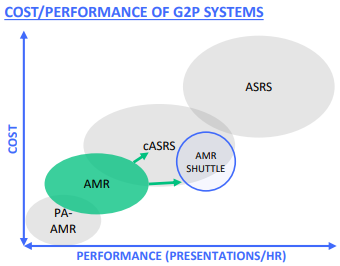

There are several types of Goods-to-Person (G2P) systems available on the market, including:

1) Automated Storage and Retrieval Systems (ASRS)

2) Cube Automated Storage and Retrieval Systems (cASRS)

3) Autonomous Mobile Robot (AMR) Shuttles

4) Picking Assist Autonomous Mobile Robots (PA-AMRs)

Source: STIQ research & analysis

Bin-to-person robots are actually referring to the above systems, in the fact that the differences of the above systems are the flexibility and storage density. Of course, there are no systems perfect for all cases.

For example, ASRS and cASRS are relatively higher storage density but lower flexibility. While AMR Shuttles and PA-AMRs are known as the most flexible solutions.

Flexible AMR Shuttles provided:

1) Adapt to peak and non-peak period by adjusting the deployed robots

2) Ability to deploy robots to different sites

3) Relatively small amount of investment and scale up easily in the future

Let's look into industries that need Bin-to-person

Flexibility in Pharmaceutical

Pharmaceutical companies have realized the need to streamline their warehouse operations, build operational resilience, and secure the medical supply distribution at ground zero of the global pandemic.

(Pharmaceutical warehouse deployed RS2)

Bin-to-Person robots feature self-charging capabilities and can operate 24/7 in pharmaceutical warehouses. Navigation can be done with simple QR codes making it easy to adjust the space and to quickly add robots to expand operational capacity should a company be faced with a sudden rise in the demand for medical supplies.

Flexibility in E-commerce

Another example is in the retail industry, where the e-commerce boom has led to a high influx of products to be shipped globally. Such warehouses may see very narrow aisles to achieve the maximum storage capacity per square foot. Bin-to-person robots can come in useful, as they operate smoothly on narrow aisles and the extended arms reach new storage depth, saving up to 50% of warehouse space and helping retail companies significantly reduce warehouse rental costs.

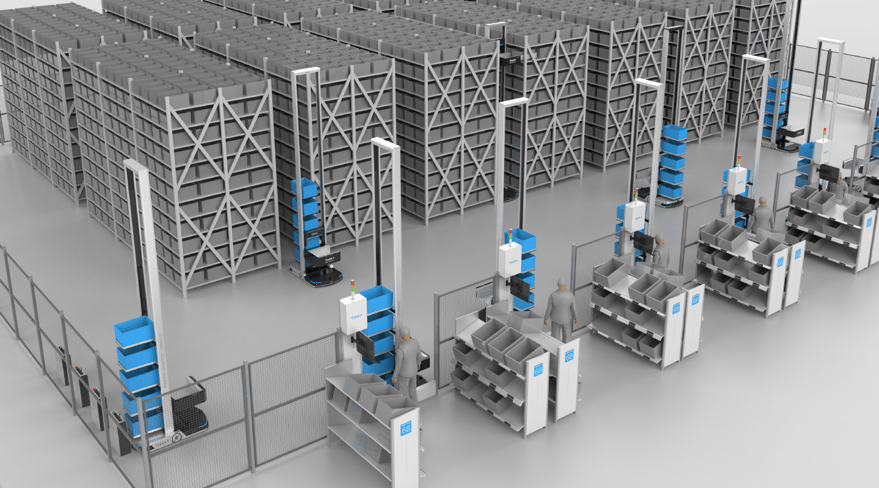

Geek+ RS2

The Geek+ RS2 bin-to-person robot is dexterous, lightweight, and can quickly navigate multi-stored shelves smoothly. The picking action is simple and efficient, and the station layout takes up a small area (more stations can be deployed in the same warehouse area, strengthening the whole warehouse throughput capacity). The picking position of the bin can be automatically adjusted to the most comfortable picking height, and there is no need to climb the ladder to maximize the picking efficiency.

RS2 can operate 0.8m narrow aisles and use its forklift arms to swiftly reach bins of ordered items and autonomously transfer them to an employee positioned at a workstation, allowing picking efficiency to improve by 300% and picking accuracy to reach 99.99%.

Geek+ RS5-D

The Geek+ RS5-D bin-to-person robot innovatively adopts the 1.4m double extension design. The robot can perform double-deep retrieval. It refreshes the effective storage range of the three-dimensional space of the robot warehouse, and the bin access range of the robot is as low as 0.215 meters and up to 5 meters, which maximizes the three-dimensional storage space.

RS5-D only needs a 1m narrow roadway, which further reduces the channel area required by robot operation and improves the storage space. By making full use of the horizontal area and vertical space, the storage capacity of RS5-D robot warehouse is 2.5 times higher than that of a manual warehouse. The gantry of RS5-D adopts a modular design, and the height can be customized according to customers' requirements.

Kai Liu, Co-founder, VP Picking & Smart Warehouse, Geek+, says: “We are excited to see our Bin-to-Person solution installed in the warehouses of leading companies and look forward to working and growing with them. By implementing the Bin-to-Person solution, we will support them with efficient, accurate, and safe warehouse operations, and the flexibility to quickly expand operations in-line with growth demands, to mitigate against sudden disruptions, and build supply chain resilience.”