Popick and Moogo Collaboration Accelerates Cold Chain Logistics Efficiency

![]()

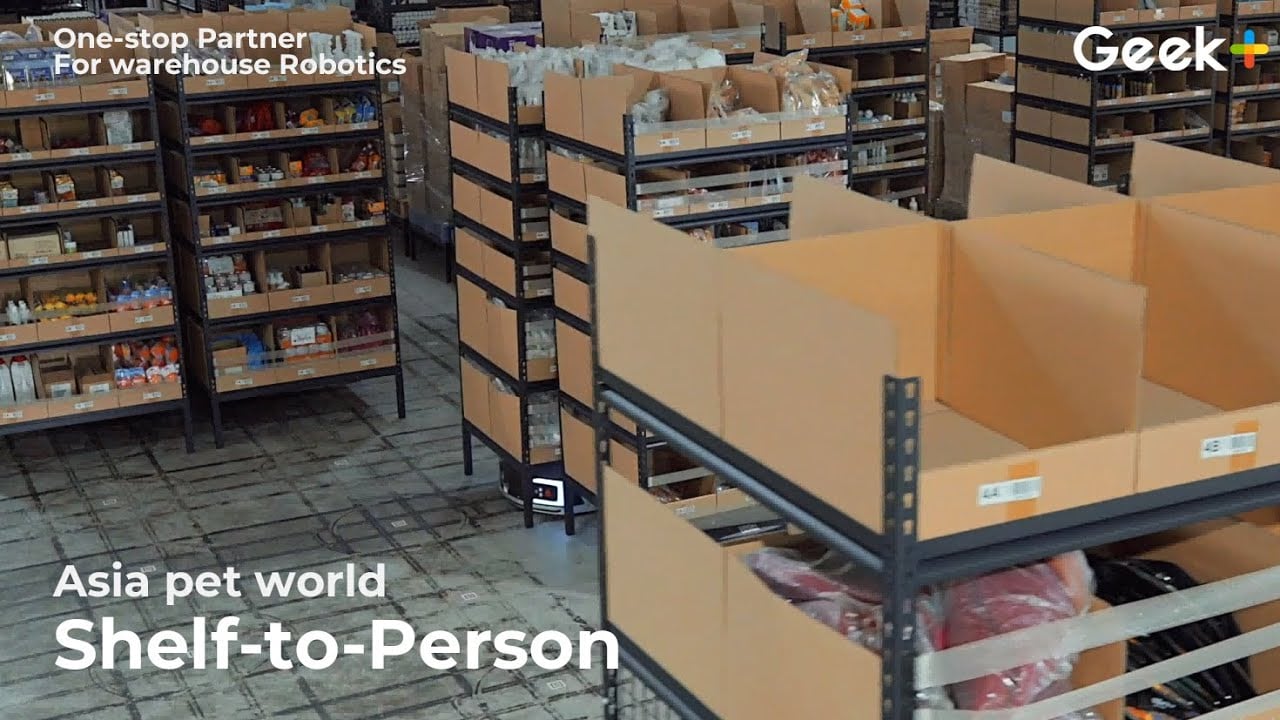

The Customer

Moogo is a prominent cross-border cold chain company in China. Their state-of-the-art temperature-controlled, automated warehouse occupies over 3,000 square meters in the Ningbo Free Trade Zone. Moogo is dedicated to optimizing storage and distribution while catering to the rigorous demands of e-commerce and supply chain logistics.

The Challenge

-

Inefficient storage systems for managing a high volume of SKUs.

-

Rising pressure from rapid e-commerce development and increased order volumes.

-

High expectations for delivery speed.

-

Complex inventory consisting of multiple product types and sizes requiring enhanced management systems.

Our Solution

Geek+ provided Moogo with the Popick "goods-to-person" picking solution. Key aspects of the solution included:

- Optimized goods-to-person picking powered by advanced robotics.

- Efficient automation to streamline warehouse operations and reduce manual intervention.

- Enhanced inventory management systems ensuring accurate real-time tracking and categorization.

The Geekplus impact

The implementation of Geek+'s solution delivered exceptional results for Moogo:

-

4x Increase in Storage Density — Optimizing the use of space compared to conventional light shelving systems.

-

4x Improvement in Workforce Productivity — Empowering employees with automation to focus on high-value tasks.

-

Enhanced Inventory Management — Modernized systems for efficient tracking and categorization of varied stock.

-

Unmatched Throughput Performance — Meeting the demands of high business volume with ease and reliability.

Video